PRODUCT CATALOG

WINTEK provides diversified high-quality products to global customers, including fiber laser cutting machines, tube laser cutting machines, sheet and tube laser cutting machines, handheld laser welding machines, laser cleaning machines, hydraulic bending machines, etc.

Sheet & Tube Laser Cutting Machine

Sheet and tube laser cutter offers seamless transitions between sheet cutting and tube cutting, enabling flexible production and operational convenience.

Learn more about product

Fiber Laser Cutting Machine

Sheet metal laser cutting machine is suitable for cutting various metal materials, including stainless steel, carbon steel, aluminum, copper, etc.

Learn more about product

Tube Laser Cutting Machine

Support various shapes cutting, Pipe, Tube, L-beam, T-beam, H-beam, I-beam, etc. With nesting software to efficiently optimize cutting paths and layouts for pipes.

Learn more about product

Hydraulic Press Brake

Bending machine is an important metal processing equipment that provides high-precision, high-efficiency and highly automated bending solutions.

Learn more about product

Portable Laser Cleaning Machine

Laser rust removal machines are efficient, eco-friendly, and versatile, ideal for metal, coating, oil stains, dirt, rust, plating, paint, and complex cleaning tasks.

Learn more about product

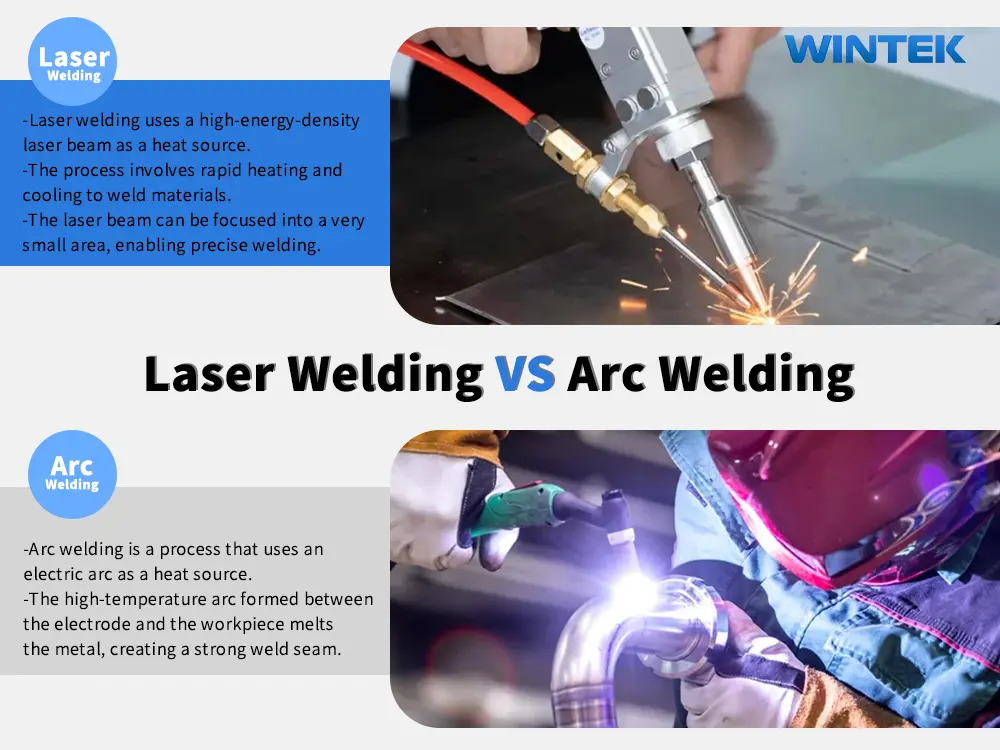

Handheld Laser Welding Machine

Hand laser welding machines can achieve fine welding, with a small heat-affected zone, uniform and flat welds, no welding marks, and beautiful appearance.

Learn more about product

Wintek Laser Machine Manufacturer

600,000+

Equipment Manufactured

25 +

Countries Exported

12 +

Years of Laser Experience

5000 +

Satisfied Customers

Why Choose Us – Focus on Quality & Service

WINTEK strives to provide customers with the most satisfactory equipment, supported by a rigorous quality control department and a professional after-sales team, always ready to resolve any issues. We prioritize quality, strictly controlling every step of the production process, including precision milling, high-temperature aging treatment, and accuracy testing. Additionally, wintek laser provides flexible OEM and ODM services to meet your specific needs.

- Customization Service

We can provide customized laser cutting machines to meet your specific needs, including machine design, color, configuration, software, and automation system, to achieve more efficient and precise processing results.

- Trusted for Over 10 Years

With over 10 years of experience in laser cutting industry, we provide advanced solutions that ensure precise, efficient, and innovative service. Trust our expertise to help your business thrive in an evolving industry.

- Competitive Price

We offer affordable, high-quality fiber laser cutting machines with cost-effective solutions tailored to your needs. Choose Wintek for advanced technology, durability, and reliability at a budget-friendly price.

- Standard Production Process

Every machine undergoes strict testing and inspection to ensure durability, precision, and top-notch performance. This comprehensive process ensures reliable, high-quality results for customers across various applications.

- Global Certification

We have CE and FDA certification and are committed to delivering high-standard products and service. These certifications ensure strict quality at every stage, offering reliable, durable, and high-performance solutions.

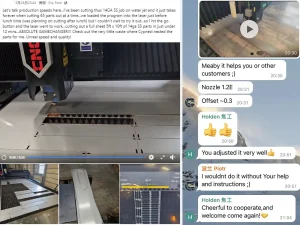

- After-Sales Support

Our dedicated team will help you solve problems, troubleshoot, provide expert advice, and offer support to ensure your products perform at their best, maximizing equipment lifespan and improving efficiency.

How to Cooperate with Us?

At WINTEK, we prioritize understanding your needs to provide customized laser solutions. From consultation to after-sales support, our streamlined process ensures exceptional results. Here’s how we collaborate with you:

Get a Quote Now

01 Consultation & Proposal

We begin with a comprehensive consultation to understand your specific requirements. Tailored recommendations are provided to align with your business goals, ensuring an informed decision.

02 Agreement & Production

We commence production after confirming the scope and terms through a detailed agreement. Our advanced manufacturing process and rigorous quality control ensure products meet the highest standards.

03 Delivery & Ongoing Support

Once production is complete, we ensure safe delivery and provide installation assistance. Our team offers technical support, repair, and maintenance to guarantee smooth operation.

Customer Feedback

OEM & ODM

WINTEK established an experienced R & D team to provide customers with various solutions, which can update and innovate regularly. Customization including Logo, Color, Appearance and Solution according to your job.

Warranty & Service

Warranty Period :

2 years for laser source / 3 years for machine

Technical Support :

Whole lifetime / Online technical support / On-site installation + training