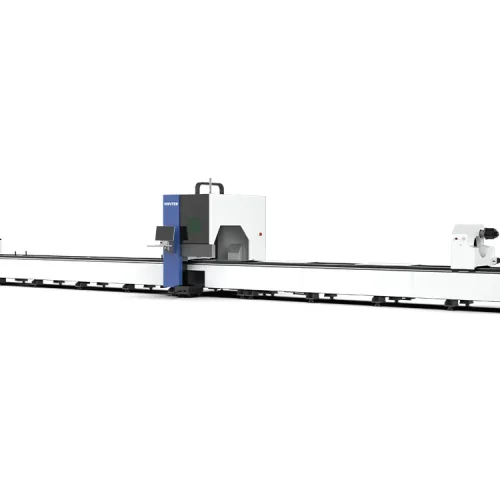

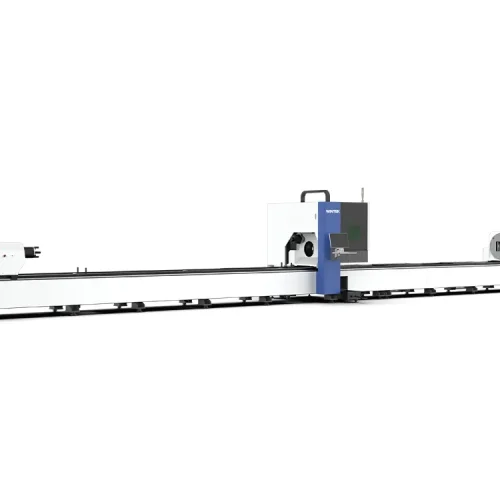

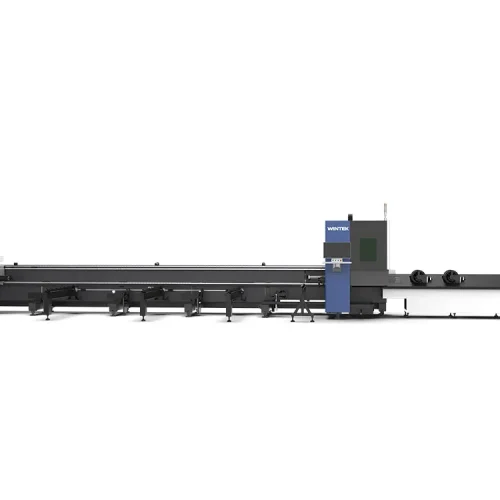

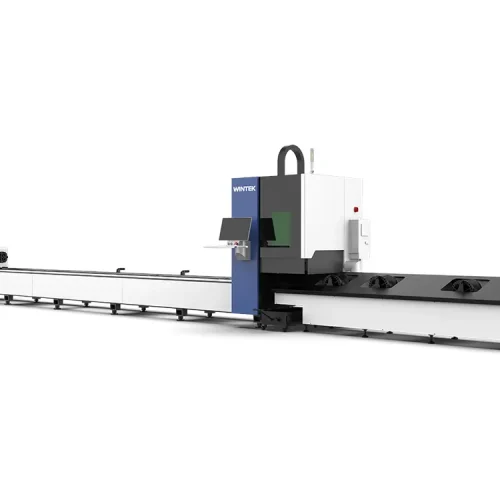

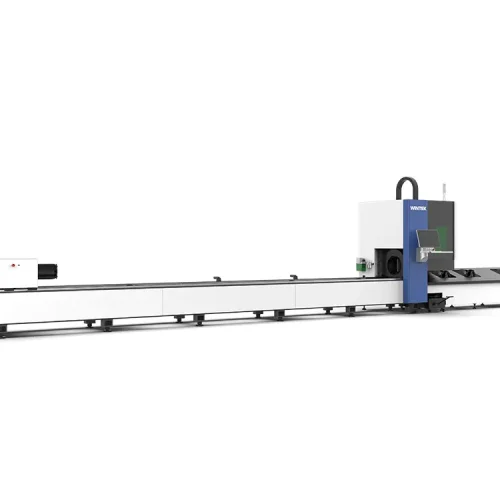

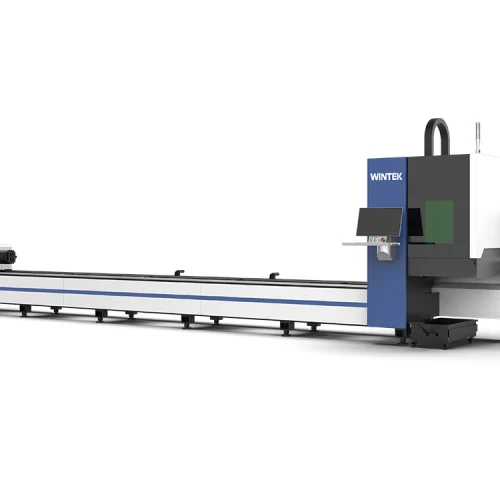

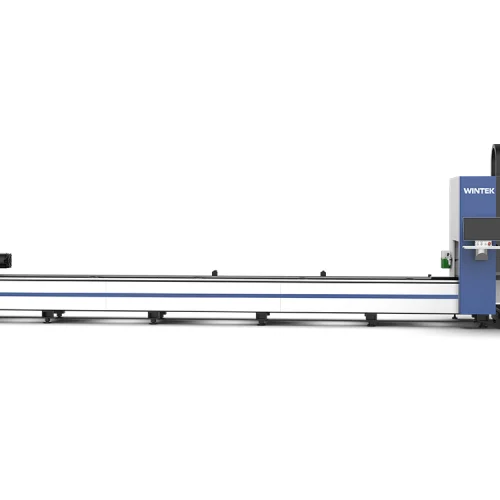

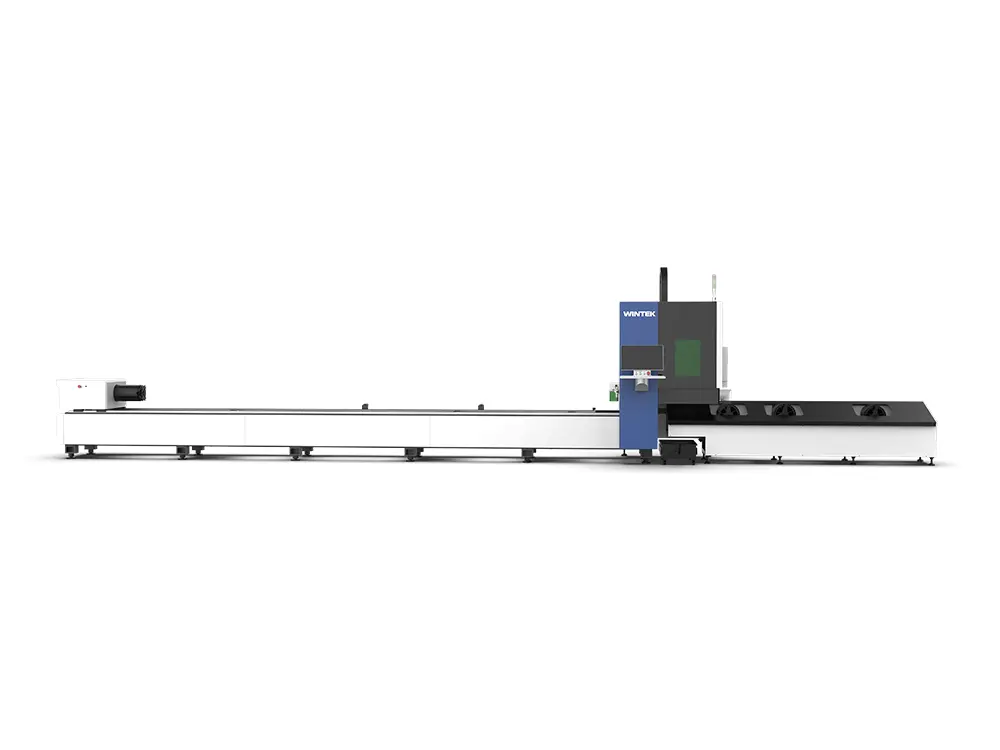

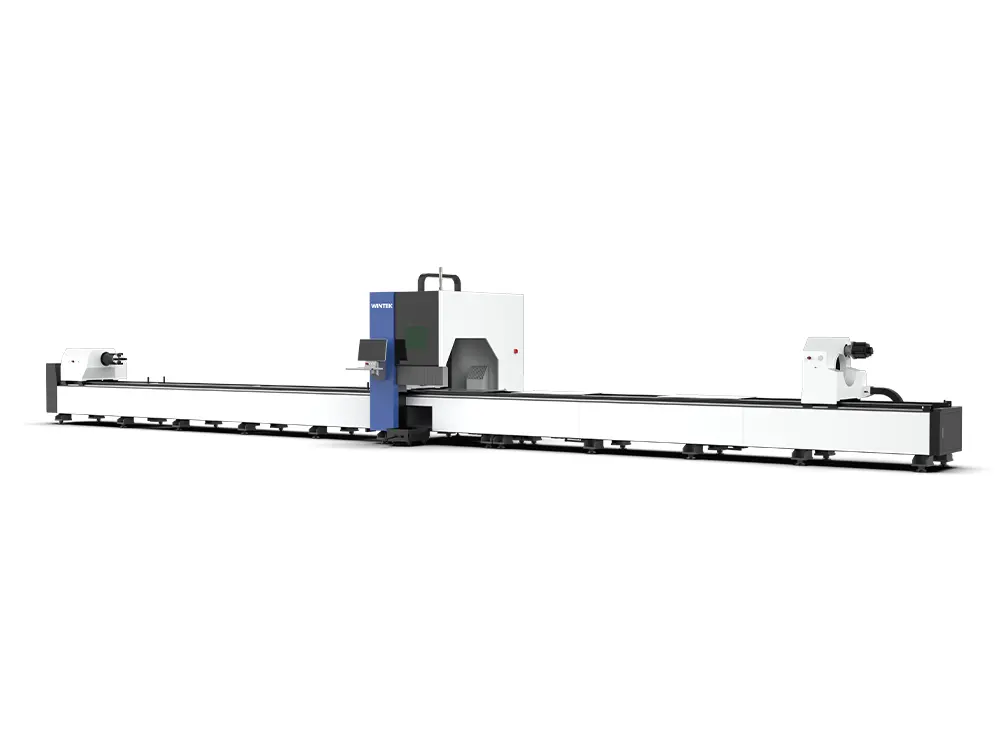

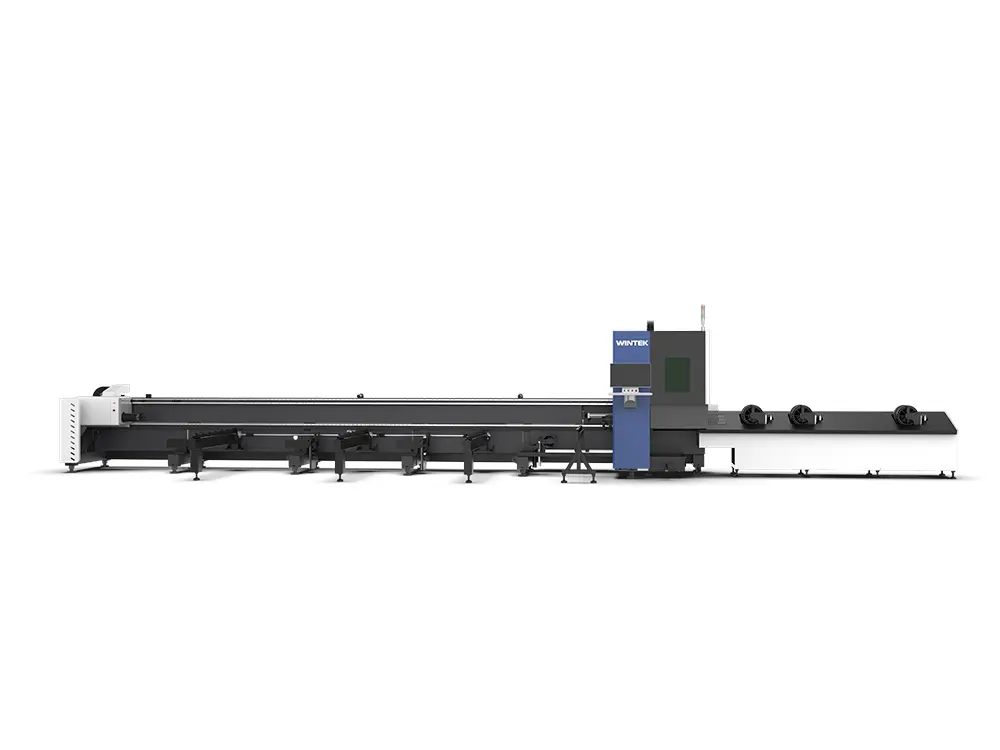

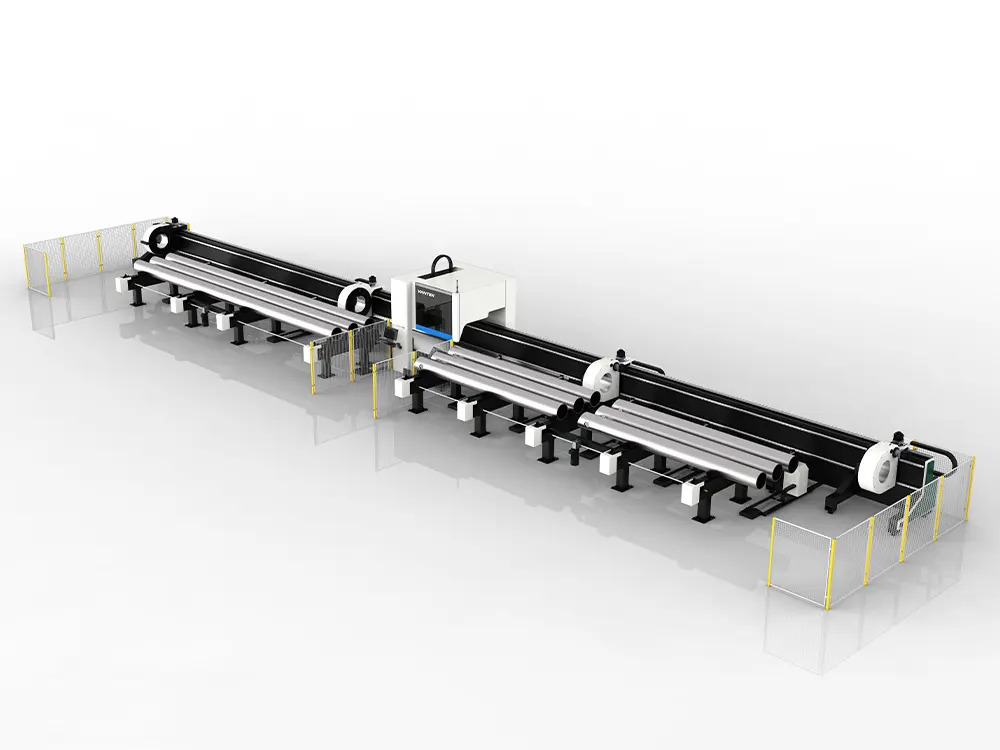

Tube Laser Cutting Machine

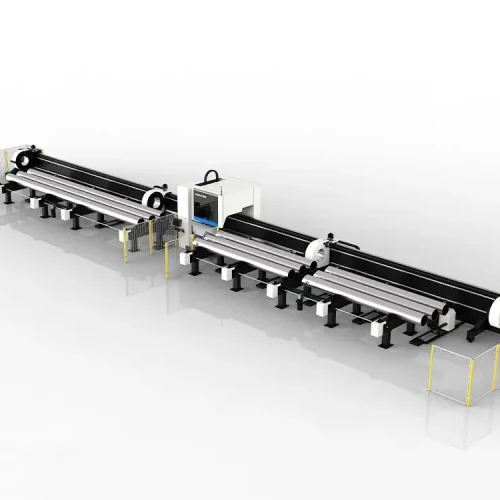

WINTEK tube laser cutting machine is mechanical equipment specially used for cutting metal tubes. It can meet different production needs, cut tubes efficiently, and ensure tube quality and dimensional accuracy. This versatile machine handles a wide range of shapes, including round, square, rectangular, O-shaped, triangular, L-shaped, H-shaped, channel steel, and other custom profiles, making it an ideal choice for various processing requirements.

(Wintek pipe diameter: 20-120mm/ 20-170mm/ 20-240mm/ 20-350mm | Wintek length range: 6000mm/ 9000mm/ 12000mm)