Tube Laser Cutting Video On Youtube

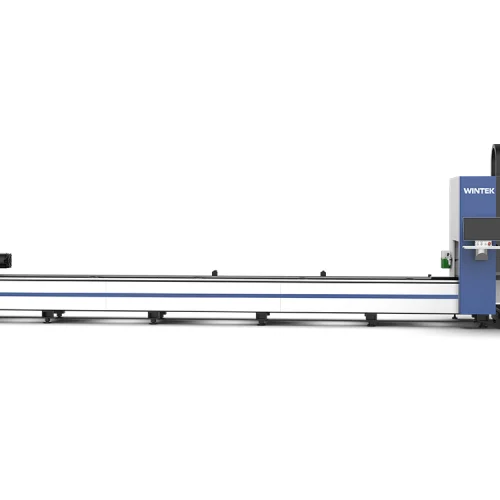

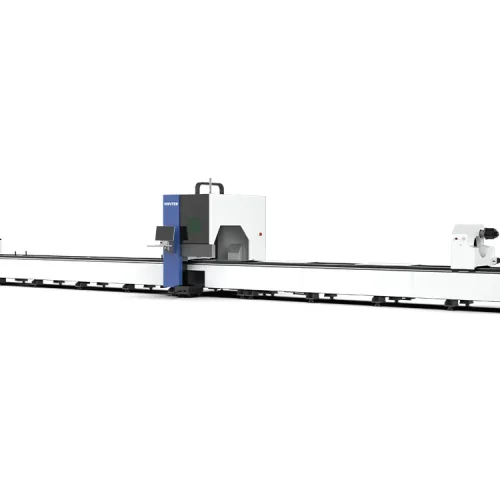

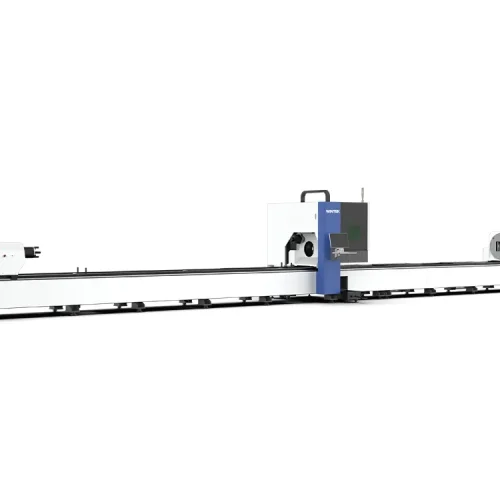

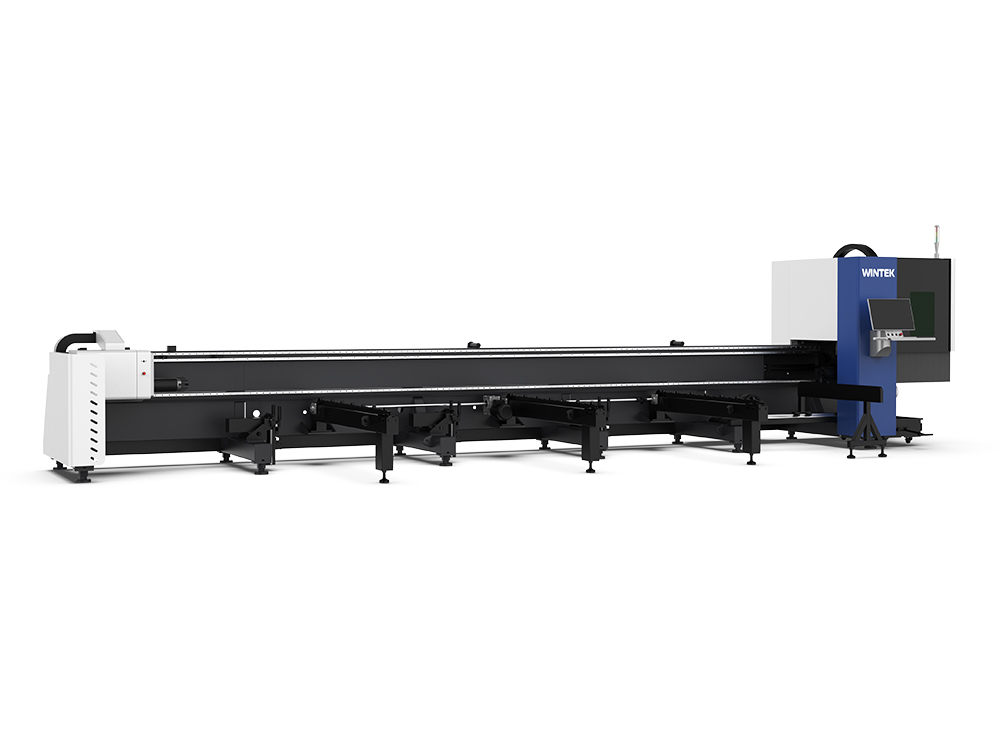

Fiber Laser Tube Cutting Machine Description

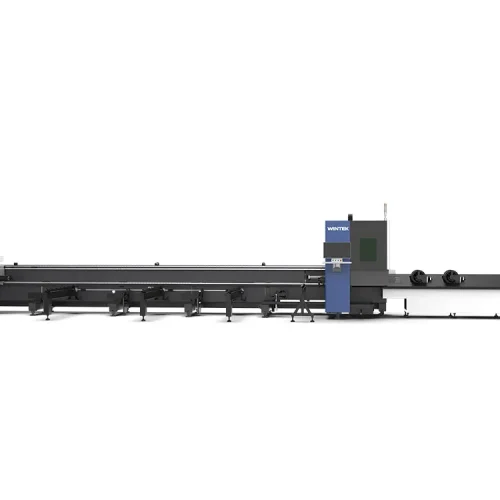

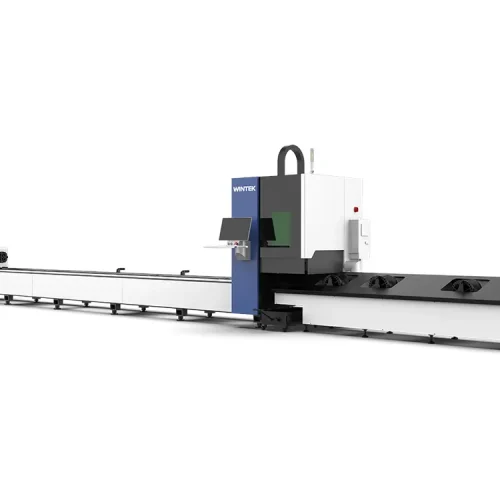

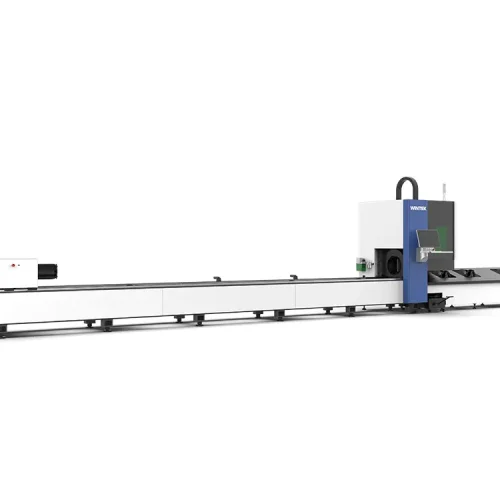

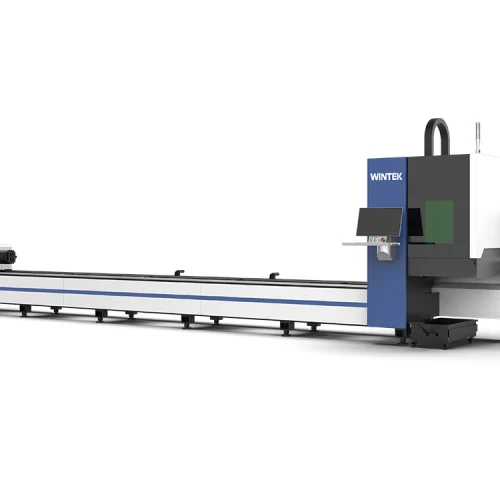

Wintek semi-automatic pipe laser cutting machine is compact and practical in appearance design. Its semi-automatic feeding system with side-hanging structure greatly reduces manual operation links and improves feeding efficiency.

The semi-automatic loading fiber laser tube cutting machine offers efficient and precise cutting for various metal pipes. The side-suspension machine structure allows for uninterrupted operation with loading without stopping. During cutting, it follows the contact surface of the pipe, moving up and down. When changing the pipe, the support height is automatically set according to the drawing, eliminating the need for adjustments.

Featuring a semi-automatic loading system, it streamlines material handling while maintaining high accuracy and performance. Ideal for medium to high-volume production, this machine combines advanced fiber laser technology with user-friendly operation, ensuring consistent results and optimized productivity.

Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT6012T | WT6020T | WT6035T |

| Max. processing tube length | 6300mm | 6300mm | 6300mm |

| Cutting diameter | 20-120mm | 20-240mm | 0-350mm |

| Maximum tube weight | 100kg | 300kg | 900kg |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck rotating speed | 200r/min | 120r/min | 80r/min |

| Y axis maximum speed | 130m/min | 110m/min | 80m/min |

| X axis maximum acceleration | 1.5G | 1.5G | 0.8G |

| 20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| Dimensions | 8700*2400*2000 | 9250*2635*2350mm | 9250*2780*2370 |

Tube Laser Cutting Machine Sample

Machine Configuration

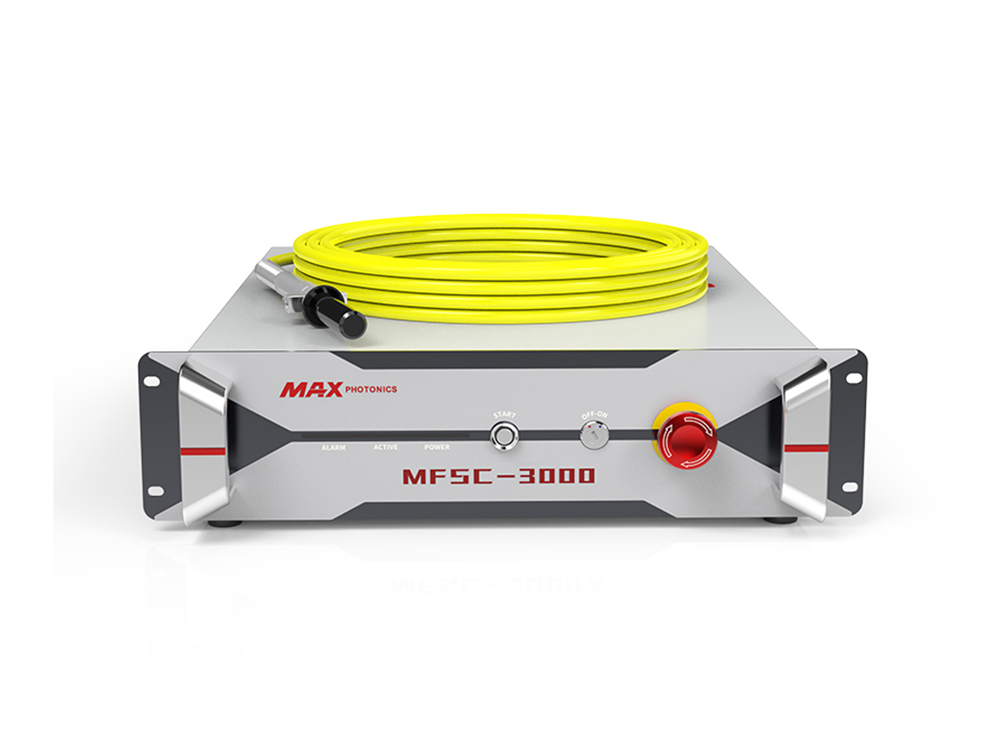

High-Efficiency Laser Source

We use high-quality MAX lasers with stable performance, delivering excellent beam quality, finer cutting lines, higher work efficiency, and superior processing results, ensuring reliable and consistent operation.

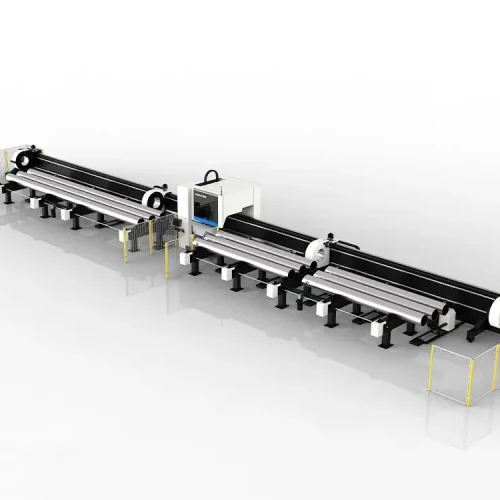

Automatic Loading Device

The automatic loading device automatically completes the delivery and initial positioning of the pipe, greatly reducing the time of manual loading. Especially for large diameter or heavy pipes, loading is easier and safer.

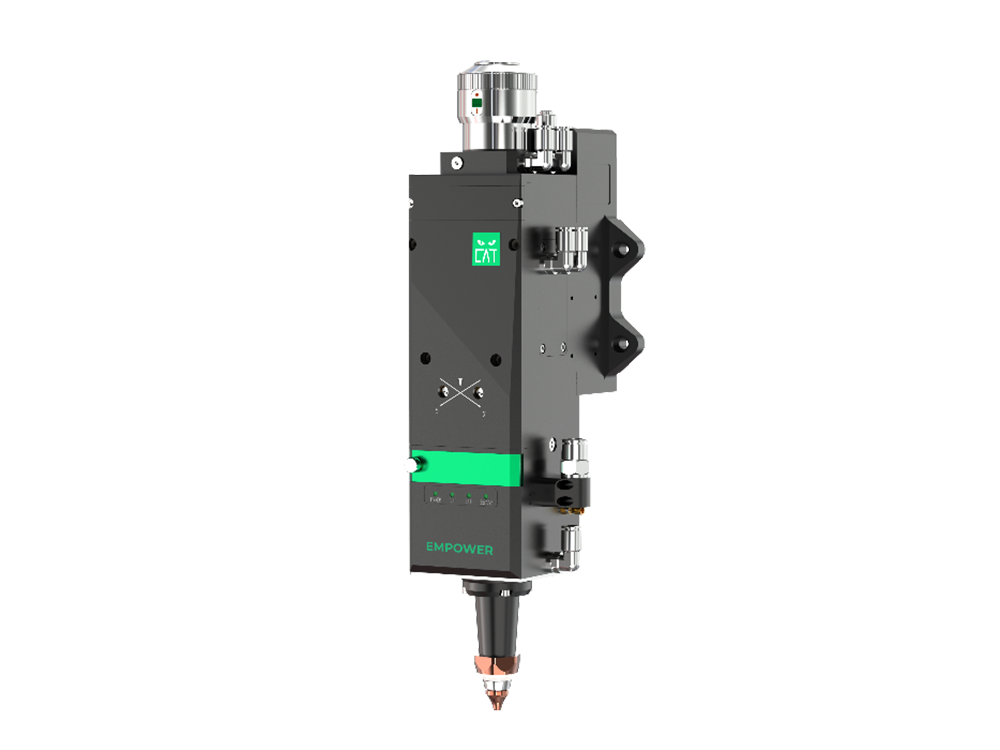

Intelligent Cutting Head

The laser cutting head can be adjusted to the best focal length to ensure excellent cutting performance with smooth and clean edges. It efficiently handles complex cutting paths such as circles, curves, and irregular shapes, delivering high-precision cuts to meet specific design requirements.

Intelligent Cutting System

The system enhances tube laser cutting machines with automated path optimization, real-time monitoring, and material recognition, ensuring high precision and efficiency. It supports complex designs, reduces processing time, and minimizes material waste.

Tube Laser Cutting Machine - Other Core Components

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Rear Chuck

Water Cooler

Tube Laser Cutter Benefits

1. Improve production efficiency: The semi-automatic feeding system reduces manual operation time, enhancing efficiency, especially for mass production.

2. The semi-automatic design makes operation easier. The operator only needs to set up and monitor, which reduces the technical requirements for operation and the training cost.

3. Strong adaptability: It can adapt to pipes of different sizes and materials, meet diverse production needs, and has high flexibility.

4. Stable cutting quality: The precise cutting head and automatic feeding system work together to ensure the quality and accuracy of each cut, and the cutting seam is smooth.

5. Improved safety: The high degree of automation reduces the safety hazards during manual operation and improves operational safety during the production process.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.