Tube Laser Cutting Video On Youtube

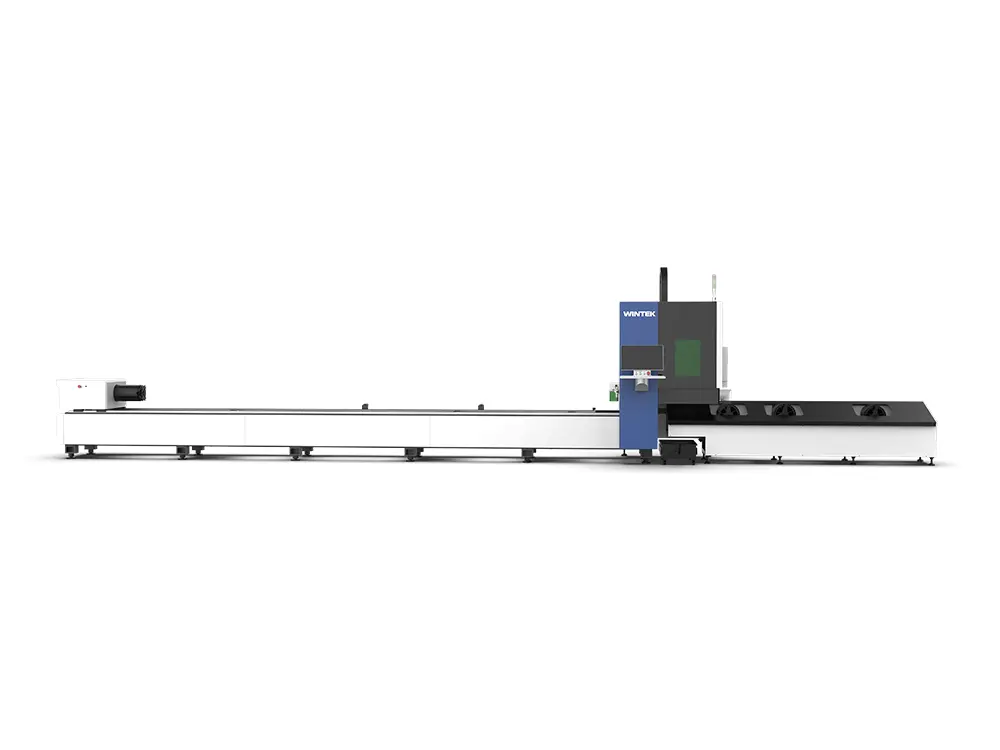

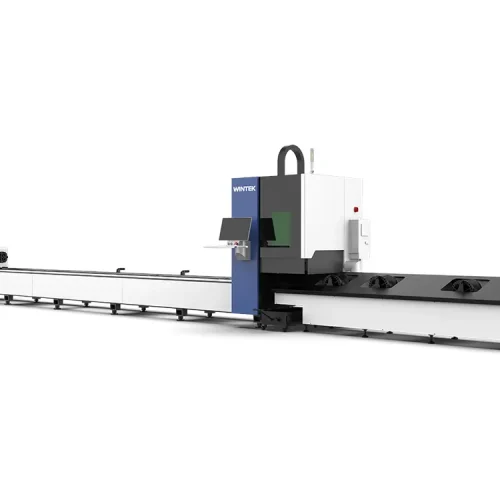

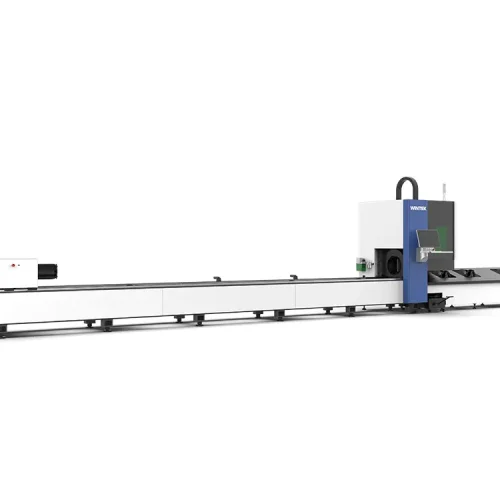

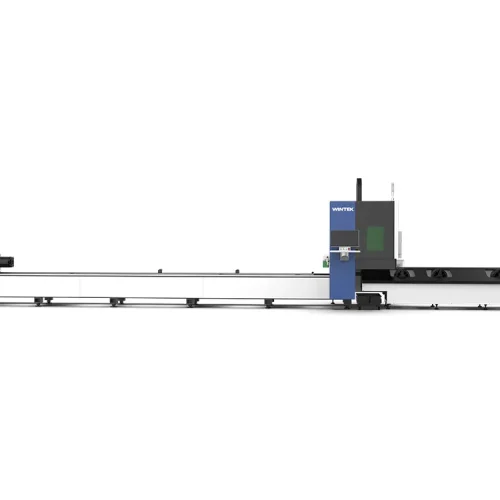

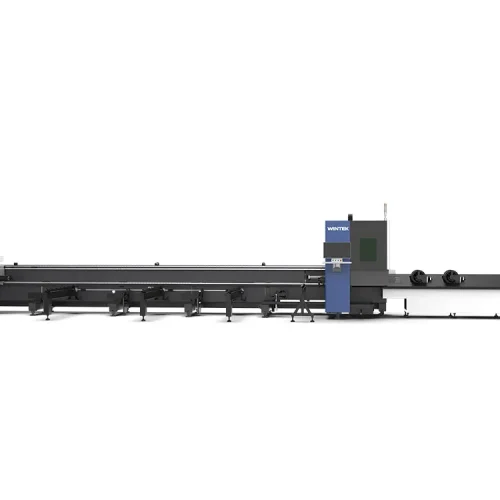

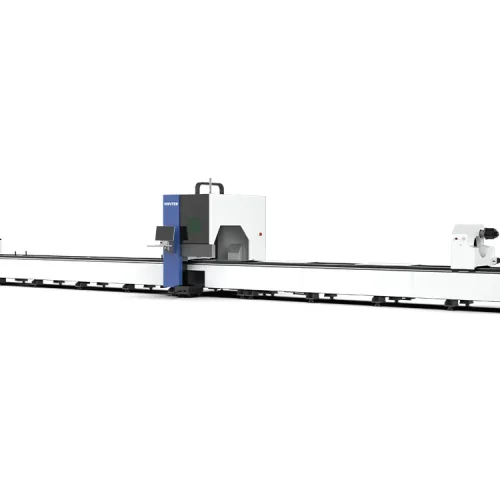

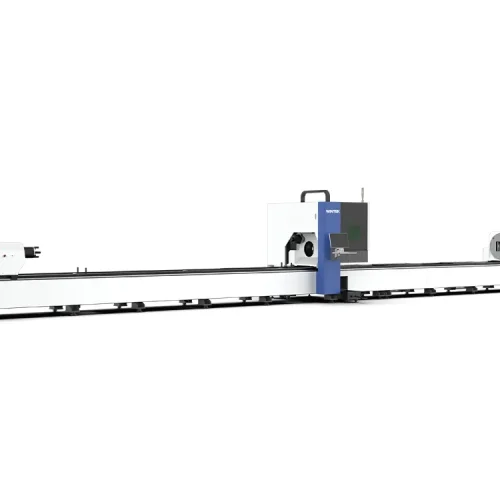

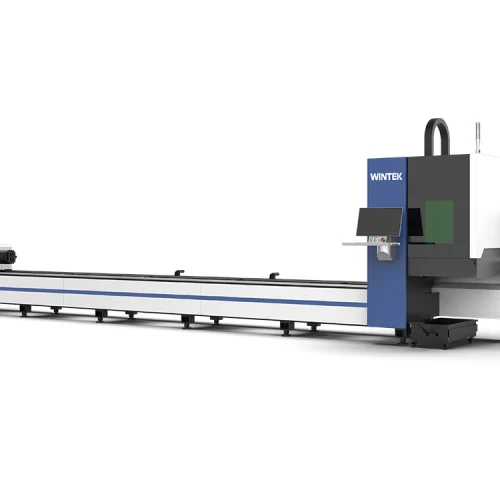

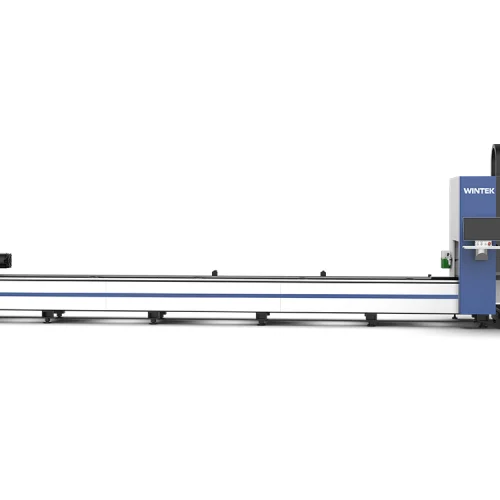

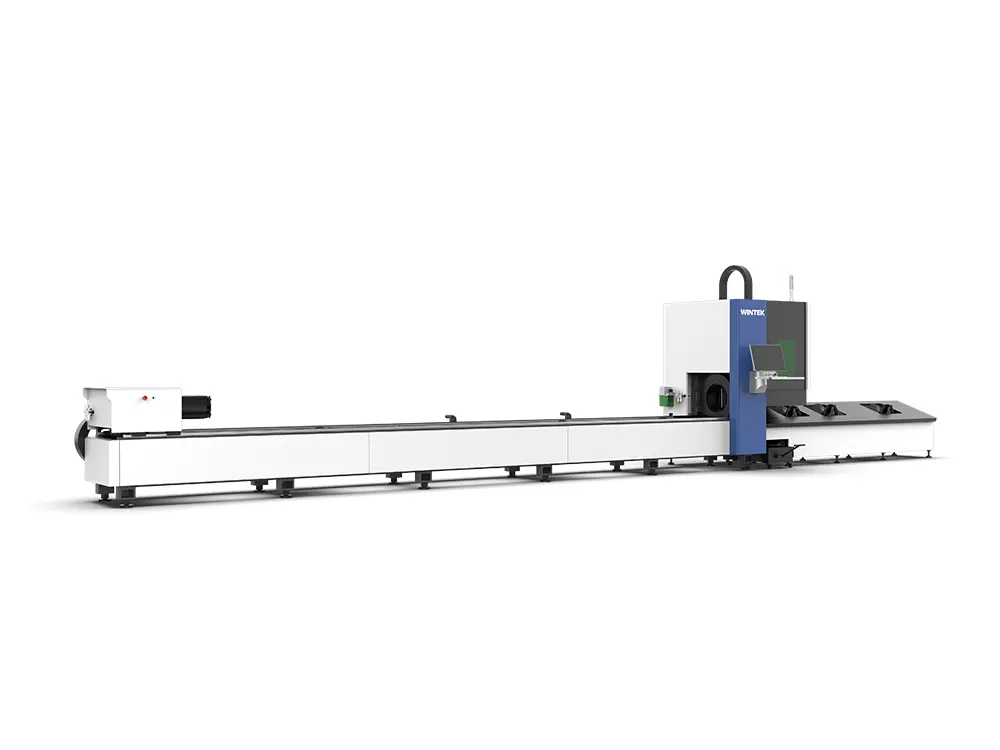

▍Pipe Laser Cutting Machine Description

The laser tube cutting machine is an efficient and precise device that uses laser beams for cutting pipes, offering several notable advantages. Firstly, it achieves high-precision cutting with smooth and neat edges, eliminating the need for secondary processing. The machine can handle various shapes and sizes of metal pipes, and the cutting process does not involve direct contact with the material surface, avoiding deformation or damage caused by mechanical forces. Compared to traditional cutting methods such as mechanical or plasma cutting, the laser tube cutting machine significantly increases cutting speed, saving 50%-90% of the time. It can cut several meters of pipe in just one minute, greatly enhancing production efficiency.

The machine is equipped with high-quality lasers and a stable mechanical structure, ensuring long-term operation with low maintenance costs. Even under high-load production conditions, it maintains efficient and stable cutting performance. With advancements in technology, modern laser tube cutting machines are also equipped with a follow-up system that automatically adjusts the height and angle of the cutting head, ensuring that the laser head stays parallel to the material surface throughout the cutting process, resulting in consistent cutting quality. The follow-up system responds in real-time to changes in the material surface, further improving the stability and consistency of the cutting process.

Additionally, the laser cutting process is environmentally friendly, as it concentrates energy, minimizes the heat-affected zone, reduces material waste, and generates less exhaust, making it more sustainable. These features make the laser tube cutting machine an indispensable tool in modern pipe processing industries.

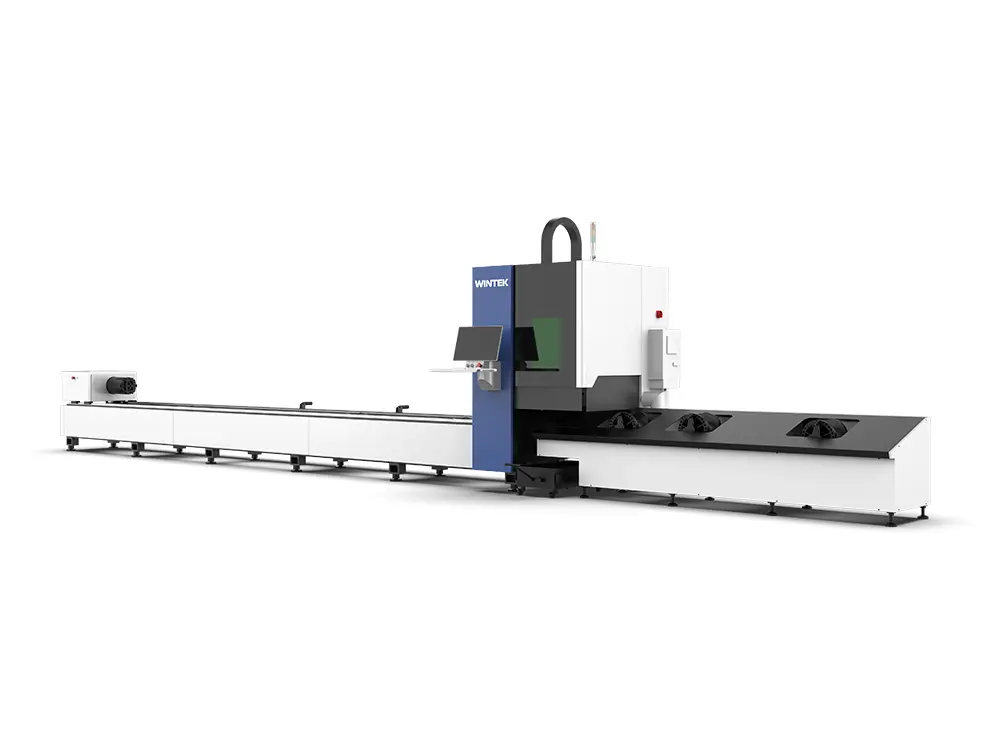

▍Pipe Laser Cutting Machine 1KW-6KW Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT6012T | WT6020T | WT6035T |

| Max. Processing Tube Length | 6300mm | 6300mm | 6300mm |

| Cutting Diameter | 20-120mm | 20-240mm | 0-350mm |

| Maximum Tube Weight | 100kg | 300kg | 900kg |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning Accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck Rotating Speed | 200r/min | 120r/min | 80r/min |

| Y Axis Maximum Speed | 130m/min | 110m/min | 80m/min |

| X Axis Maximum Acceleration | 1.5G | 1.5G | 0.8G |

| Dimensions | 11750*1490*2210mm | 11870*1500*2220mm | 12280*1720*2300mm |

| Laser Power Range | 1000W-6000W | 1000W-6000W | 1000W-6000W |

| Supported Materials | Carbon Steel, Stainless Steel, Aluminum | Carbon Steel, Stainless Steel, Aluminum | Carbon Steel, Stainless Steel, Aluminum |

| Operating Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz |

▍Pipe Laser Cutting Machine Sample

▍Pipe Laser Cutting Machine Configuration

High-Efficiency Laser Source

MAX lasers have excellent beam quality, which can ensure that the laser beam is output more evenly and stably, ensuring high precision during the cutting process. High-quality beams help improve the smoothness and processing quality of the cutting surface and reduce burrs, slag and other undesirable phenomena.

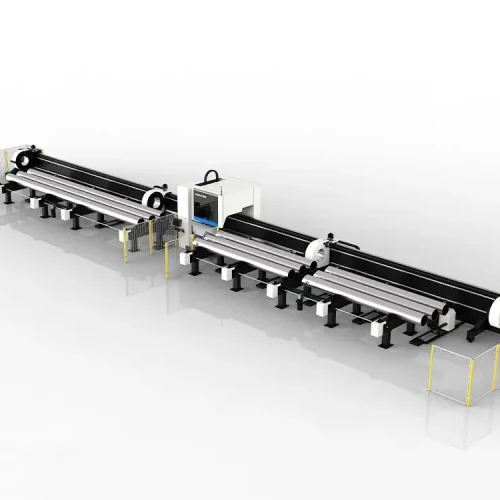

Unloading Table

Automatic collection, sorting and transportation of pipes after cutting improves production efficiency and reduces manual intervention.

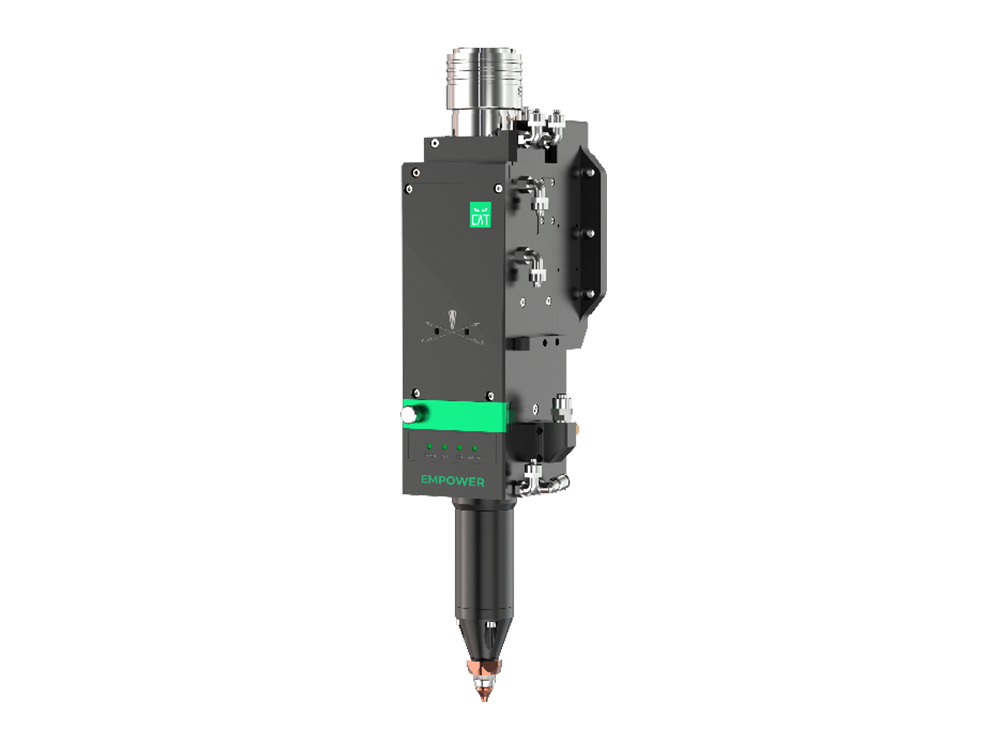

Intelligent Cutting Head

The cutting head is equipped with an advanced intelligent control system that can automatically adjust laser output parameters such as power, frequency, and pulse width to ensure the best cutting effect for different materials, thicknesses and shapes.

Intelligent Cutting System

The system offers personalized customization options based on the specific needs of different customers, including customizations for laser power, cutting range, processing modes, and more. This flexibility allows the equipment to adapt to various processing scenarios and industry requirements.

Tube Laser Cutting Machine - Other Core Components

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Rear Chuck

Water Cooler

▍Pipe Laser Cutting Machine Benefits

1. Enhanced Cutting Stability: The material support table ensures stable support for long pipes during the cutting process, preventing movement that could affect cutting precision. This is particularly beneficial for longer or thinner pipes, maintaining consistent and accurate cutting results.

2. Reduced Material Deformation: During laser cutting, long pipes may deform due to their weight or thermal effects. The support table evenly distributes the weight of the pipes, providing additional support to minimize deformation and enhance processing quality.

3. Improved Processing Efficiency: With a support table, loading and unloading pipes become more efficient, especially for long pipes in batch processing. The support table also reduces downtime caused by material adjustments due to movement, significantly boosting production efficiency.

4. Minimized Material Waste: The material support table keeps the pipes in the correct position and angle within the laser cutter, preventing errors or waste caused by misalignment. This optimizes raw material utilization and reduces unnecessary loss.

5. Versatile Processing Capabilities: The support table accommodates pipes of varying diameters, lengths, and materials, such as carbon steel, stainless steel, and aluminum. Its flexibility meets the diverse needs of industries like construction, automotive, and furniture manufacturing.

6. Extended Equipment Lifespan: By reducing the direct impact and friction of pipes on the machine, the support table minimizes wear and tear on the equipment. This extends the machine’s lifespan and lowers maintenance and part replacement costs.

Contact us now to learn more about our advanced pipe laser cutters. Complete the form to receive a customized quote.