Tube Laser Cutting Video On Youtube

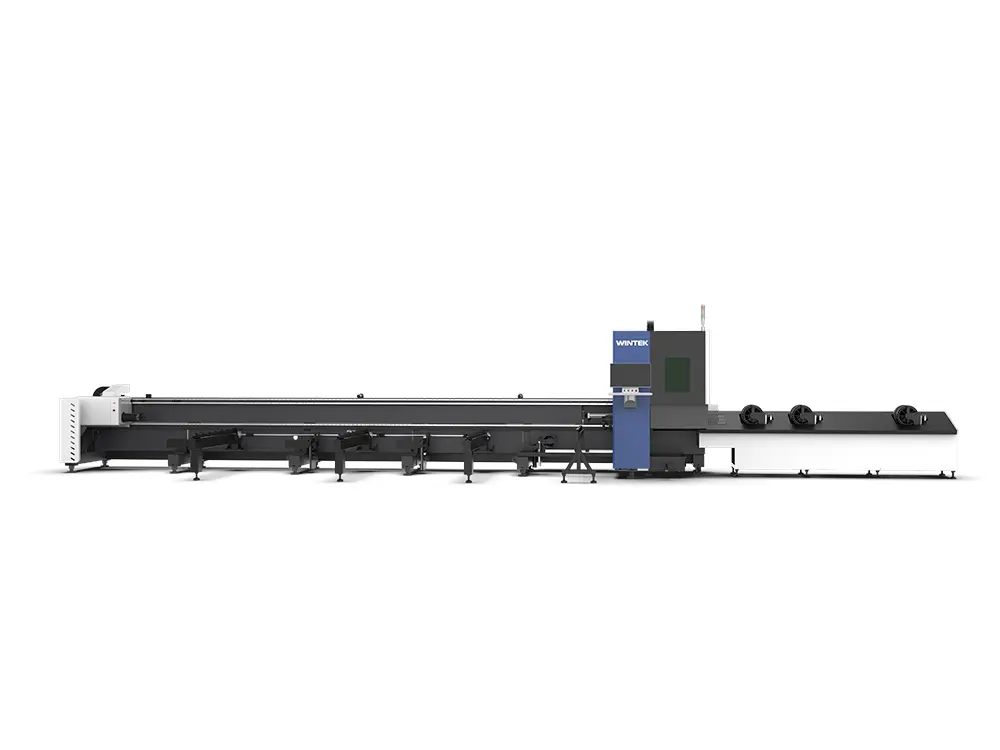

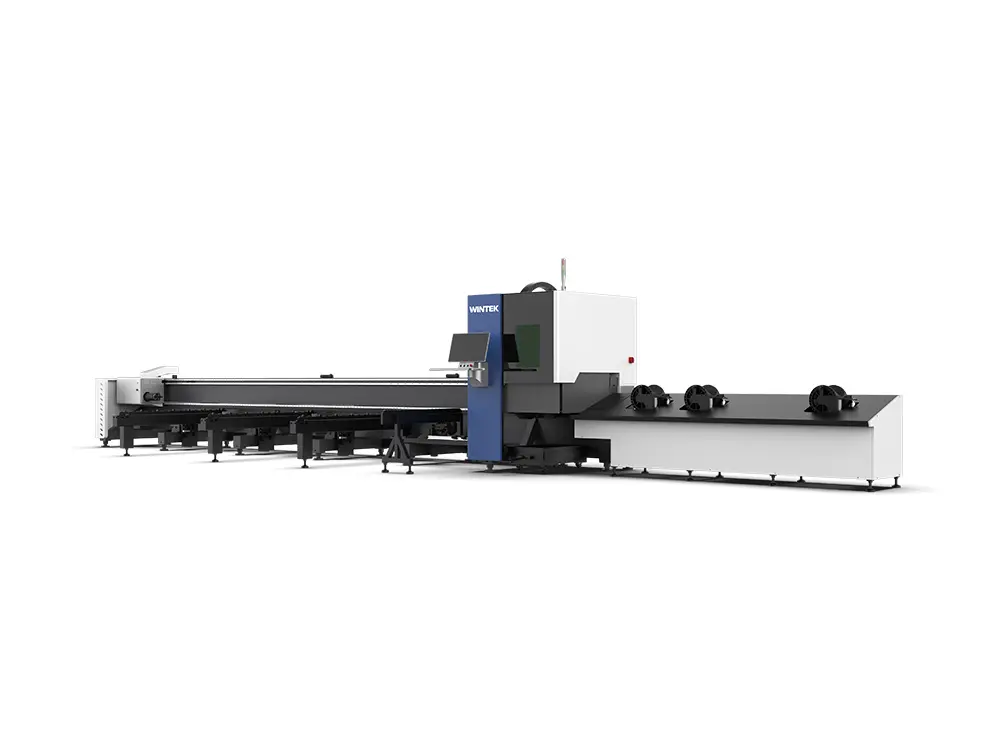

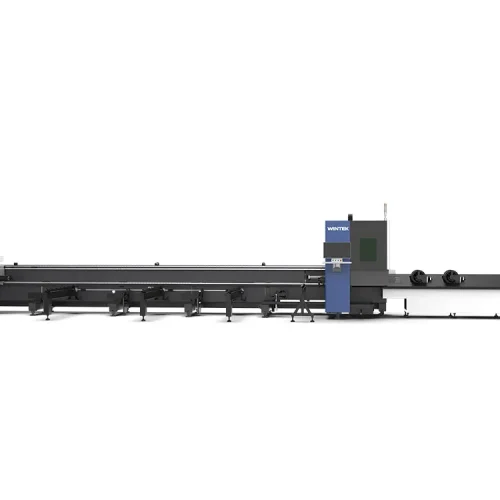

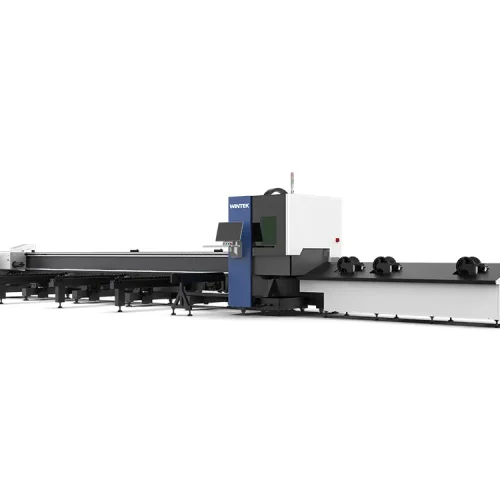

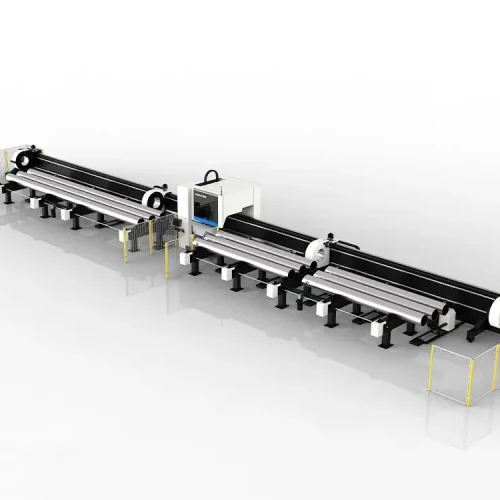

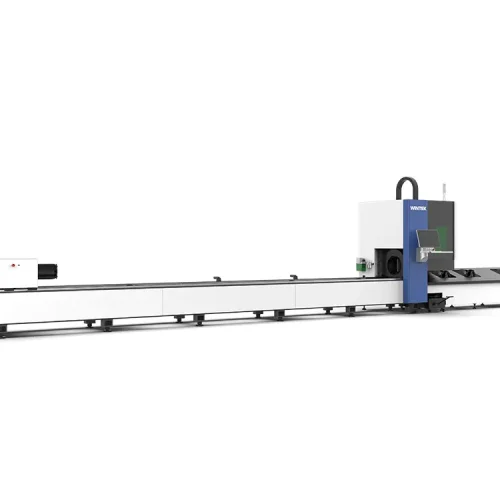

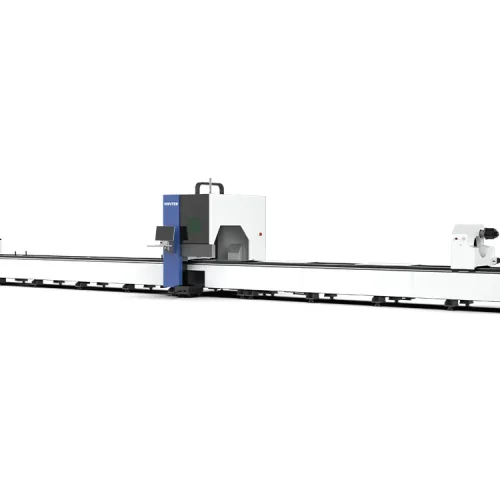

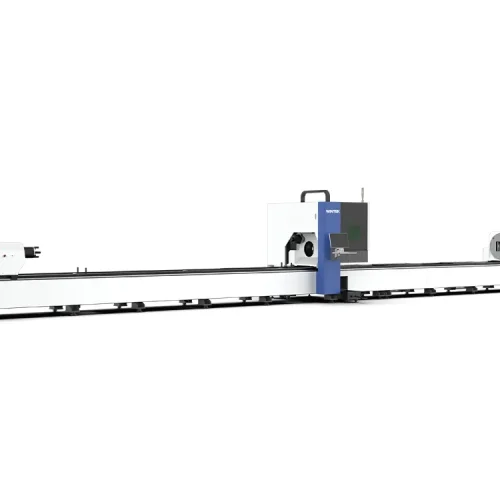

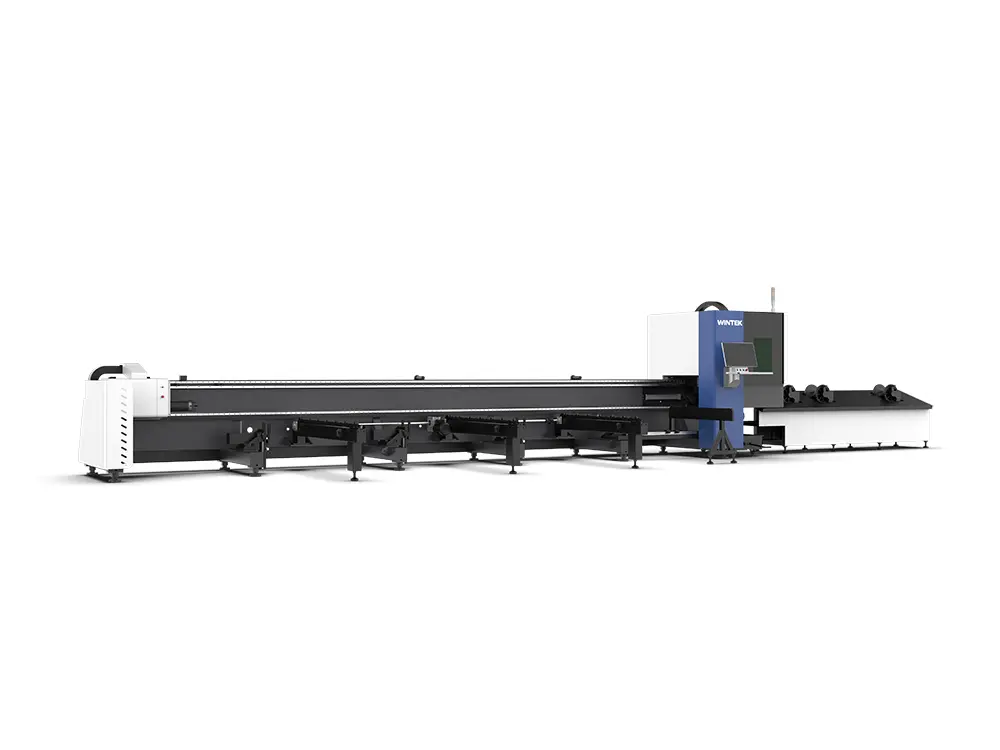

Semi-Automatic Loading Tube Laser Cutting Machine Description

The semi-automatic tube cutting machine with a discharge table is an efficient and intelligent tube cutting solution designed to enhance production efficiency and reduce manual intervention. The machine features a semi-automatic loading system that quickly feeds tubes into the cutting position, reducing loading time and labor intensity. With a simple user interface, operators can easily set cutting parameters for efficient tube cutting, making it suitable for various materials and tube specifications.

During the cutting process, the machine is equipped with advanced laser technology, ensuring precise tube cutting with smooth, burr-free edges, significantly improving the quality of the finished tubes. The cut tubes are automatically transported to the designated position by the discharge table, reducing the need for manual handling, improving discharge efficiency, and minimizing downtime caused by material transfer. This ensures a smooth and efficient cutting process.

Technical Parameters

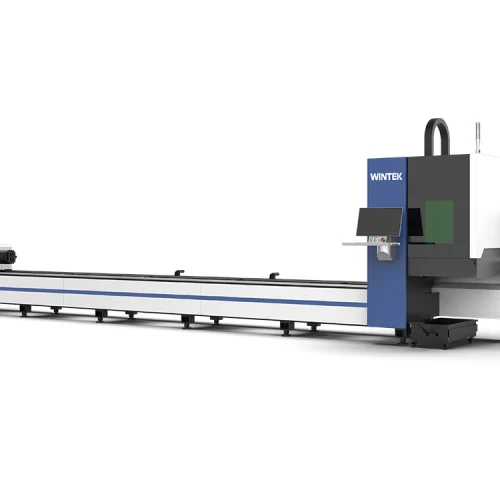

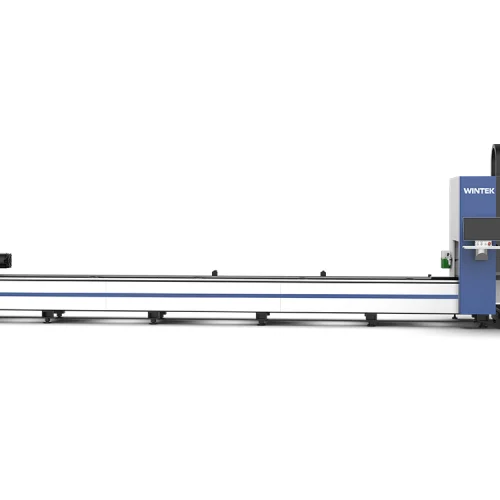

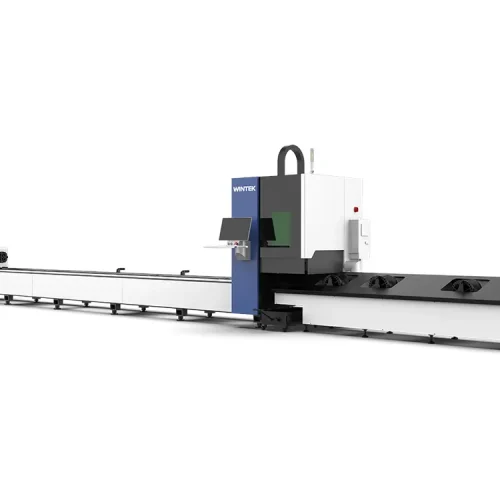

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT6012T | WT6020T | WT6035T |

| Max. processing tube length | 6300mm | 6300mm | 6300mm |

| Cutting diameter | 20-120mm | 20-240mm | 0-350mm |

| Maximum tube weight | 100kg | 300kg | 900kg |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck rotating speed | 200r/min | 120r/min | 80r/min |

| Y axis maximum speed | 130m/min | 110m/min | 80m/min |

| X axis maximum acceleration | 1.5G | 1.5G | 0.8G |

| 20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| Dimensions | 11700*2400*2000 | 12250*2635*2350mm | 12250*2780*2370 |

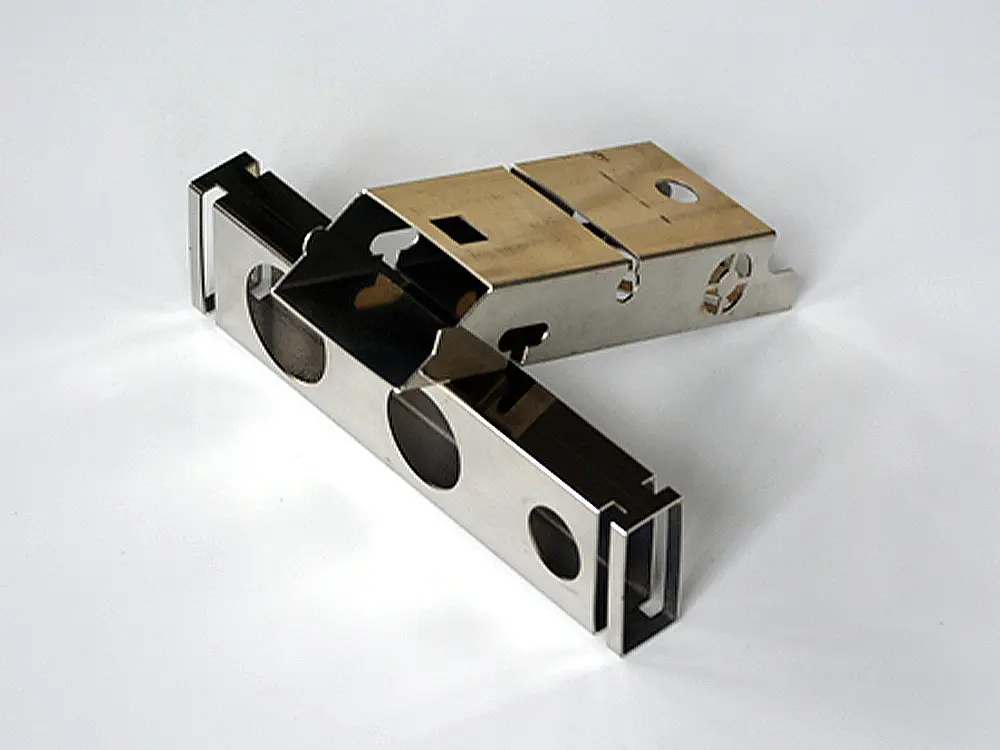

Tube Laser Cutting Machine Sample

Machine Configuration

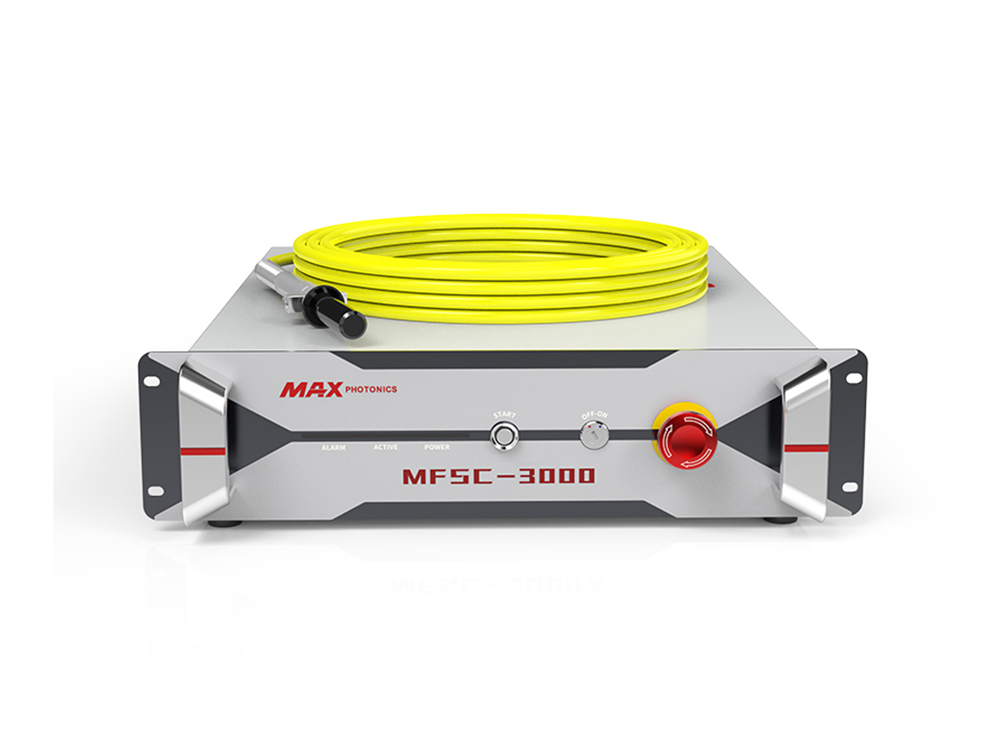

High-Efficiency Laser Source

The machine is equipped with a high-performance fiber laser, known for its high energy conversion efficiency and stable beam quality. The laser provides continuous, stable output, supporting high-speed and high-precision cutting of various metal tubes. The power and adjustment functions of the laser are automatically calibrated based on the material’s thickness and hardness to optimize cutting performance.

Sturdy And Stable Machine Bed

The bed of the semi-automatic tube cutting machine is constructed with high-strength steel welded structure, precision-machined and heat-treated to ensure stability and durability. The robust bed design effectively reduces vibrations, providing a stable cutting platform that enhances cutting accuracy and processing quality. Its compact structure makes the machine suitable for various production environments with minimal floor space requirements.

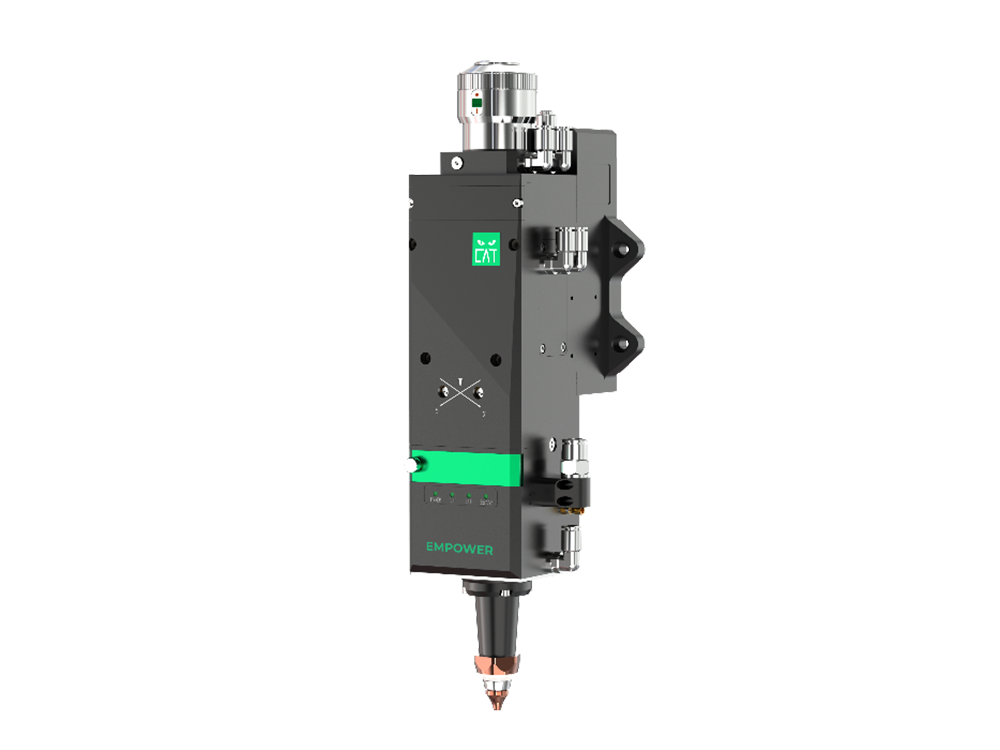

High-Precision 3D Laser Cutting Head

The cutting head is a key component, typically equipped with an automatic focusing system that adjusts the focal length based on tube size and shape to ensure optimal cutting results. The high-precision optical system guarantees stable laser beam quality, minimizing cutting errors. The cutting head also features an airflow protection system, which effectively prevents smoke and slag from contaminating optical components, extending their lifespan.

Tube Laser Cutting System

The machine is equipped with an advanced CNC system that supports intelligent operation and features a user-friendly interface for easy parameter setting and programming. The system includes real-time monitoring and fault detection functions, ensuring accuracy and safety during the cutting process. With automatic path optimization and fast cutting algorithms, the system improves processing efficiency while maintaining high cutting precision. It also supports remote diagnostics for easier maintenance and troubleshooting.

Tube Laser Cutting Machine - Other Core Components

Segmented Automatic Support

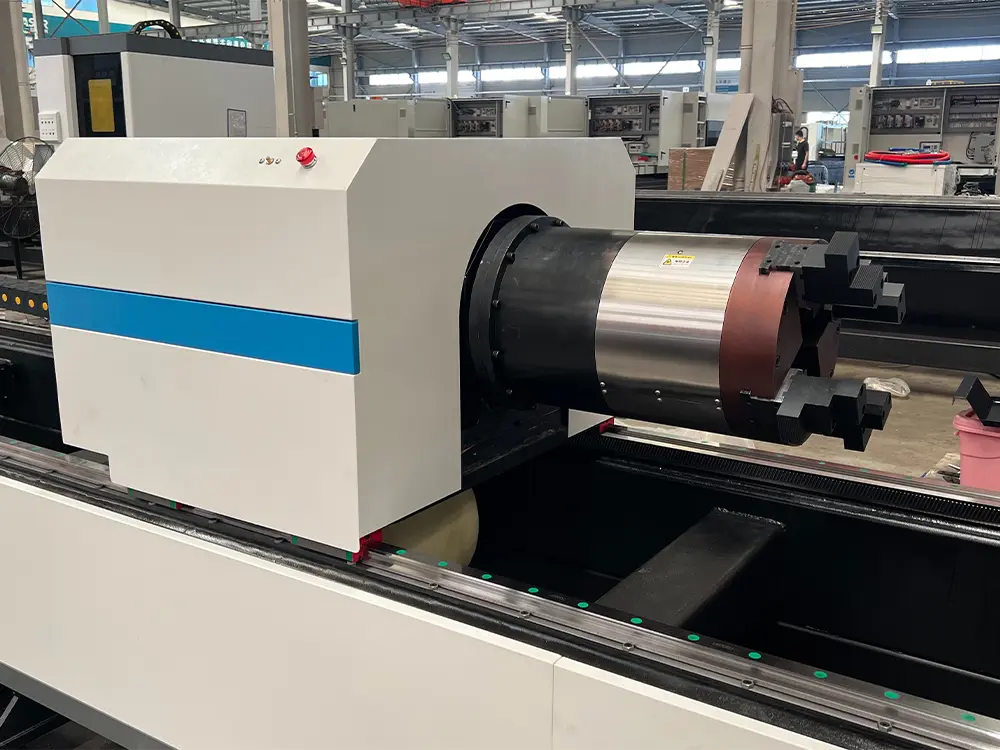

Full Automatic Pneumatic Chuck

Rear Chuck

Automatic Oil Lubrication Device

Tube Laser Cutter Benefits

1. Increased Production Efficiency: The semi-automatic loading system simplifies the tube loading process, reducing manual intervention and speeding up material handling. The cut tubes are automatically transported by the discharge table, eliminating manual handling and significantly improving production efficiency.

2. Precise Cutting and Enhanced Quality: The machine is equipped with advanced laser technology, ensuring precise tube cutting with smooth, burr-free edges, greatly improving the quality of the finished tubes and reducing the need for secondary processing.

3. Easy Operation, Reduced Labor Intensity: Featuring a user-friendly interface, operators can quickly set cutting parameters, simplifying operations and improving work efficiency while reducing labor intensity during production.

4. Labor Cost Savings: The semi-automatic loading and unloading system reduces the need for manual handling, lowering labor costs, especially in large-scale production and high-efficiency processing environments.

5. Versatile and Widely Applicable: The machine is capable of handling various tube specifications, including round, square, and irregular shapes, making it suitable for a wide range of industries such as manufacturing, construction, and furniture.

6. High Reliability and Stability: The machine’s robust structure ensures strong stability, allowing for long-term, efficient operation, minimizing downtime and equipment failures.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.