In recent years, fiber laser cleaning technology has gained popularity in various industries due to its high efficiency, eco-friendliness, and non-contact nature. It is widely used in fields such as manufacturing, shipbuilding, and precision maintenance. However, with numerous brands and models available on the market, choosing the right fiber laser cleaning machine can be challenging….

In modern industry, metal processing plays an indispensable role, with efficiency and precision being key benchmarks for evaluating processing technologies. The emergence of the 3 in 1 laser machine has brought an innovative solution to metal processing by combining welding, cutting, and cleaning functions into a single device. This 3 in 1 laser welding cleaning…

In the field of laser cleaning, fiber lasers have become the preferred light source due to their exceptional reliability, stability, and flexibility. Among these, continuous laser cleaning and pulsed laser cleaning stand out as two core technologies, each with unique advantages that have secured their prominent positions in the market. However, with diverse cleaning requirements,…

Introduction As modern manufacturing evolves, the need for precision, efficiency, and eco-friendliness in metal processing has grown significantly. While traditional welding techniques are well-established, they often fail to meet these demands. Laser welding, as a cutting-edge solution, offers unparalleled advantages with its high precision, speed, and energy efficiency, quickly becoming a preferred technology across various…

Laser rust removal machines are cutting-edge industrial cleaning tools that use high-energy laser beams to remove rust, coatings, oxide layers, or other contaminants from metal surfaces. This cleaning technology requires no chemicals, offering a more efficient and environmentally friendly alternative to traditional methods that do not damage the base material. Below is a comprehensive analysis…

Introduction Laser cutting machines are known for their high precision, fast cutting speeds, and versatility, making them an ideal choice across various industries. They deliver clean, smooth cuts with minimal material waste, ensuring efficiency and cost-effectiveness. With non-contact cutting technology, these machines experience less wear and require lower maintenance. Moreover, advanced models integrate CNC automation,…

Introduction Fiber laser cutting machines have revolutionized the metalworking and manufacturing industries with precision, efficiency, and versatility. As China continues to lead the global manufacturing market, many Chinese companies have emerged as top-tier suppliers of fiber laser cutting machines. This article explores the top 10 fiber laser cutting machine manufacturers in China, highlighting their innovative…

Laser cleaning, as a green and efficient cleaning method, is being accepted by more industries and is gradually replacing traditional cleaning methods such as sandblasting and chemical cleaning. At present, the cleaning equipment on the market is mainly handheld laser cleaning machines, which are small in size, easy to operate, and moderately priced, and are…

Introduction Laser welding is an advanced welding technique that uses a highly focused laser beam as a heat source to join materials. The process is commonly used to weld metals by directing a laser beam into the joint area, causing the materials to melt and fuse. Laser welding is known for its precision, speed, and…

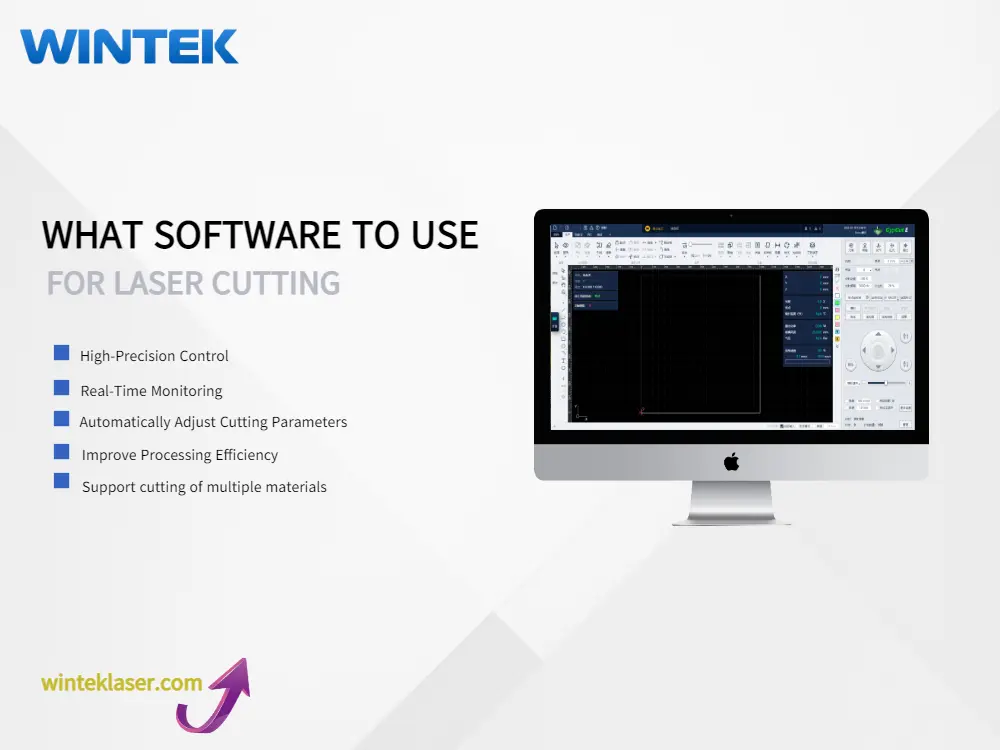

Introduction Laser cutting is a precise and efficient manufacturing process that relies heavily on software for design, control, and optimization. The right software can significantly enhance the capabilities of a laser cutting machine, allowing for complex designs, accurate cuts, and seamless workflow. This article will explore software commonly used in laser cutting and features. What…

- 1

- 2