Tube Laser Cutting Video On Youtube

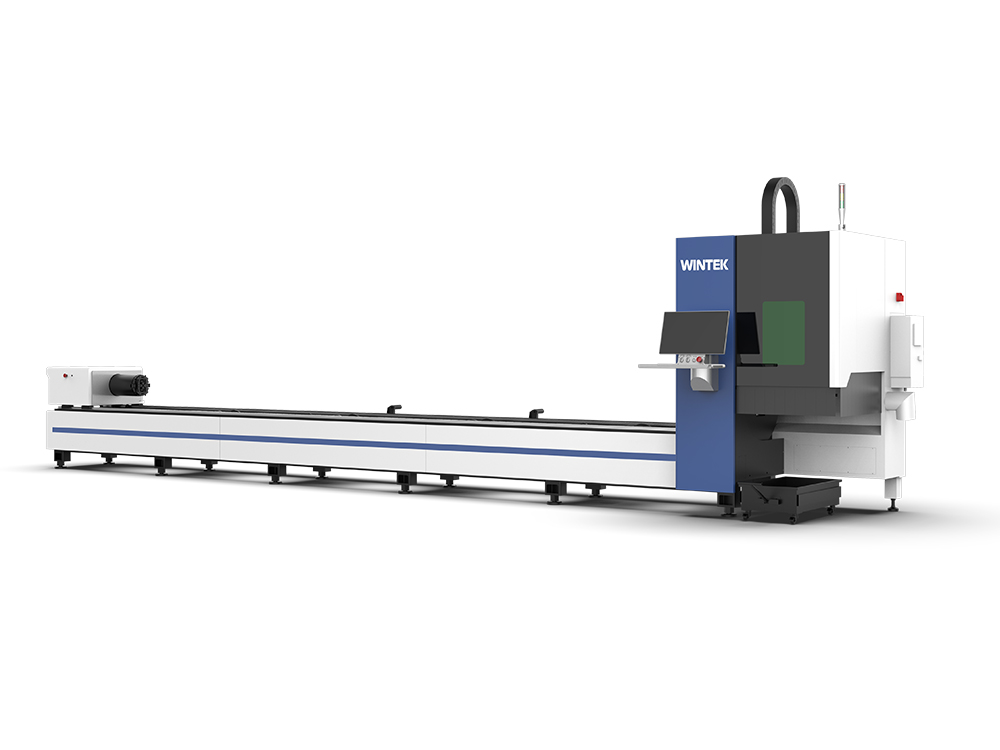

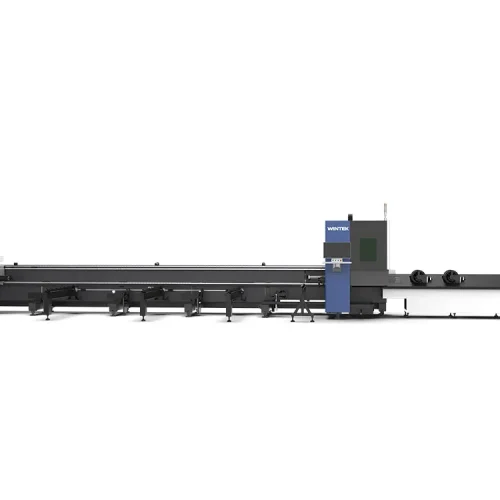

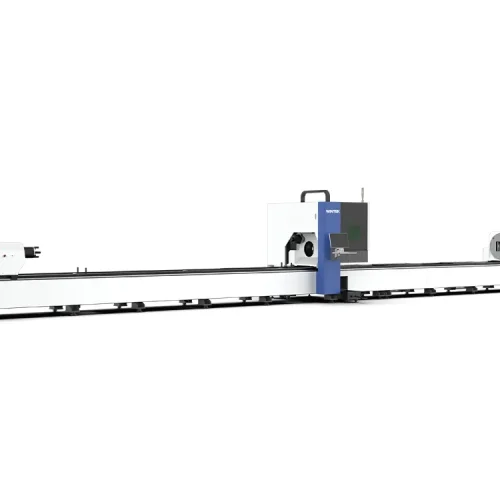

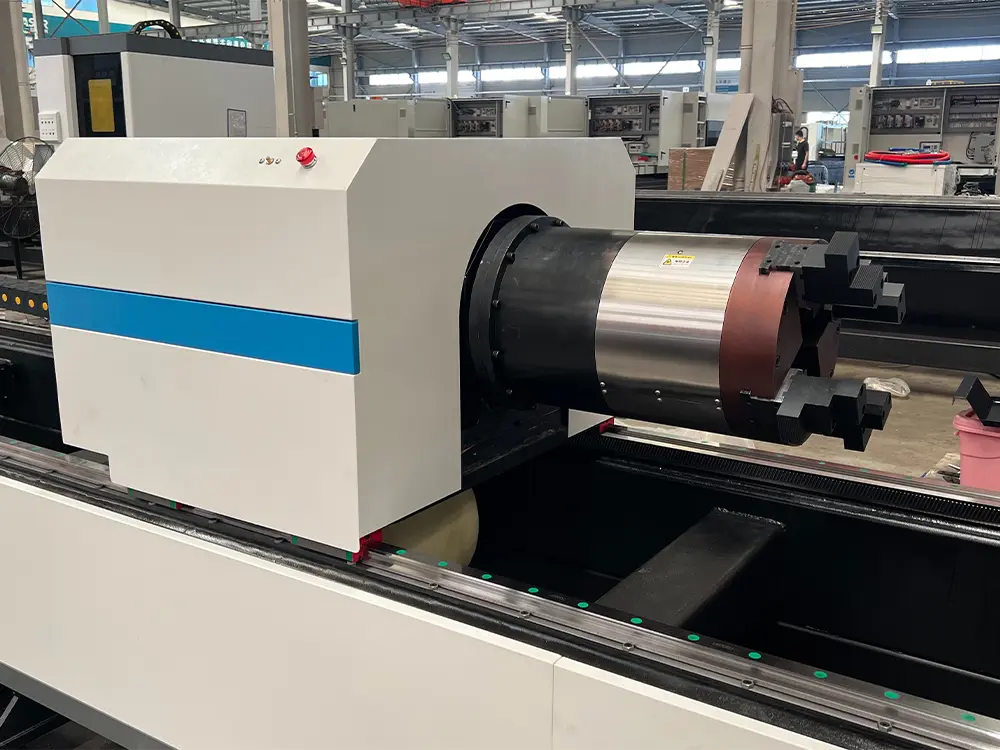

Professional Laser Tube Cutting Machine Description

The tube cutting machine is an advanced solution specifically engineered for processing various types of metal tubes, including carbon steel, stainless steel, aluminum, and more. It offers unparalleled cutting precision, smooth and burr-free edges, and minimal material waste, making it the perfect choice for industries that demand high accuracy and efficiency.

This cutting-edge machine is capable of achieving ultra-precise cuts with a minimal cutting gap and an impressive accuracy of up to ±0.05mm, making it highly suitable for complex and intricate tube designs. It supports a wide range of tube shapes, such as rectangular tubes, square tubes, round tubes, I-beams, and custom profiles, providing unmatched versatility for diverse manufacturing requirements.

Equipped with intelligent software, the laser tube cutting machine automates the generation of cutting paths, optimizes cutting sequences, and significantly reduces processing time. The software also enhances material utilization and streamlines operations, ensuring maximum productivity with minimal effort.

In addition to its high precision and intelligent features, the machine is designed for durability and reliability, ensuring consistent performance in demanding industrial environments. With a robust structure and advanced laser technology, it is an indispensable tool for industries such as automotive manufacturing, aerospace, and metal fabrication.

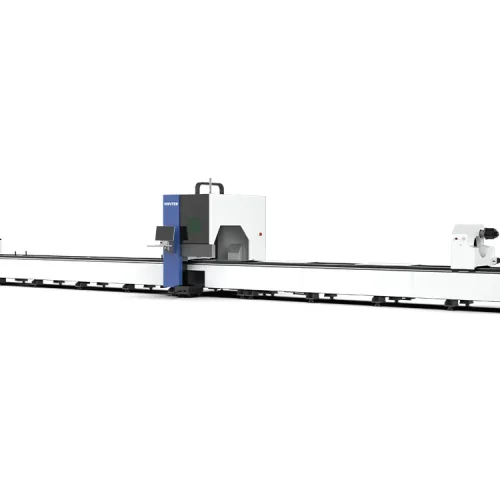

Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT6012T | WT6020T | WT6035T |

| Max. processing tube length | 6300mm | 6300mm | 6300mm |

| Cutting diameter | 20-120mm | 20-240mm | 0-350mm |

| Maximum tube weight | 100kg | 300kg | 900kg |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck rotating speed | 200r/min | 120r/min | 80r/min |

| Y axis maximum speed | 130m/min | 110m/min | 80m/min |

| X axis maximum acceleration | 1.5G | 1.5G | 0.8G |

| 20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| Dimensions | 8750*1490*2210mm | 8870*1500*2220mm | 9280*1720*2300mm |

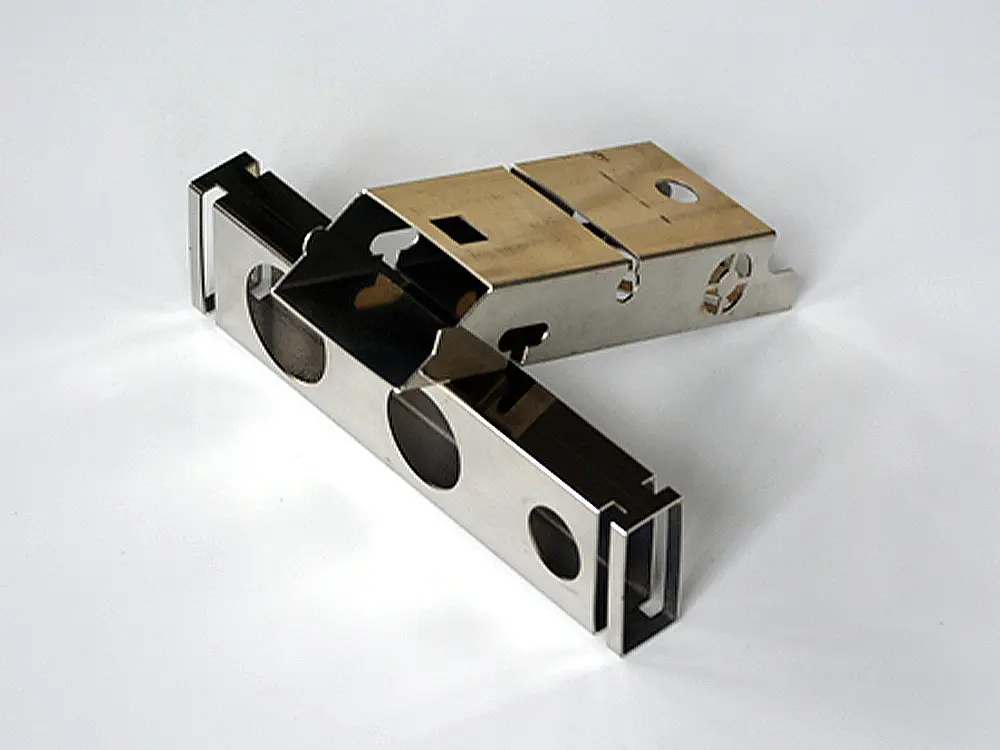

Tube Laser Cutting Machine Sample

Machine Configuration

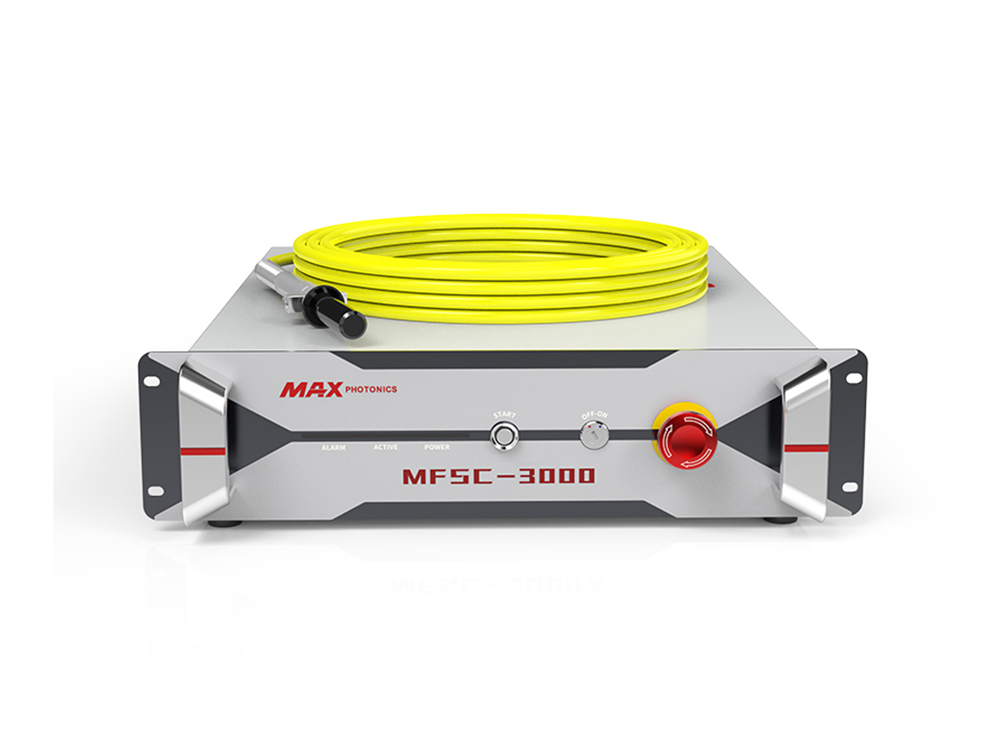

High-Efficiency Fiber Laser Source

MAX laser delivers superior beam quality, low maintenance, and energy efficiency. The focused and stable laser beam ensures fast cutting, making them perfect for thin to medium-thickness metal pipes.

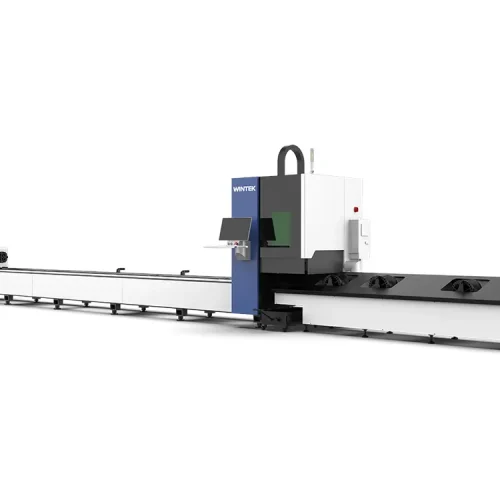

Sturdy And Stable Machine Bed

The sheet metal frame is welded with tubes and is strong and non-deformable. The surrounding hanging-mounted design is easy to disassemble and assemble, making it convenient for equipment maintenance. Many sheet metal details are rounded to prevent operators from being scratched by sharp corners.

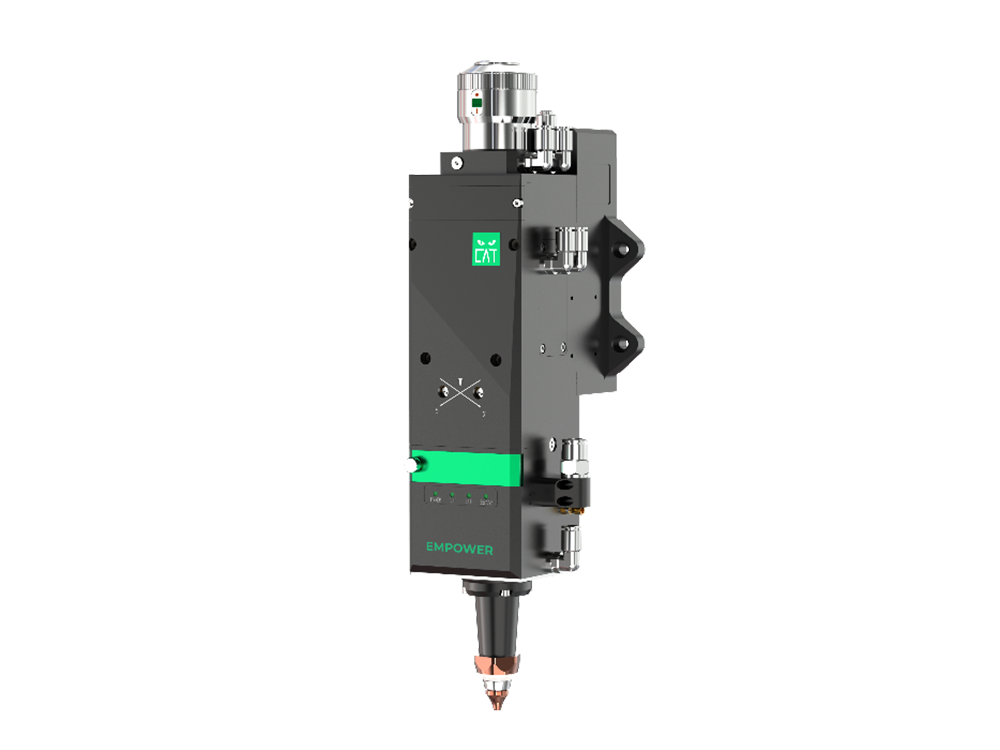

High-Precision 3D Laser Cutting Head

The cutting heads are designed for high-precision and efficient laser cutting. They offer stable performance with precise focus control, ensuring clean cuts and minimal material waste. Supports precise cutting at various angles, making it ideal for bevel cuts, chamfers, and complex joint designs.

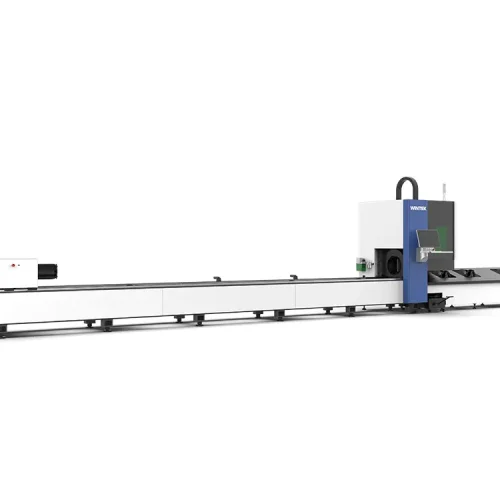

Tube Laser Cutting System

The system adopts high-response servo control to ensure a smooth and accurate cutting trajectory with an error control within ±0.1mm. The system has an anti-shake control algorithm to reduce vibration during high-speed cutting and improve the quality of the finished product.

Tube Laser Cutting Machine - Other Core Components

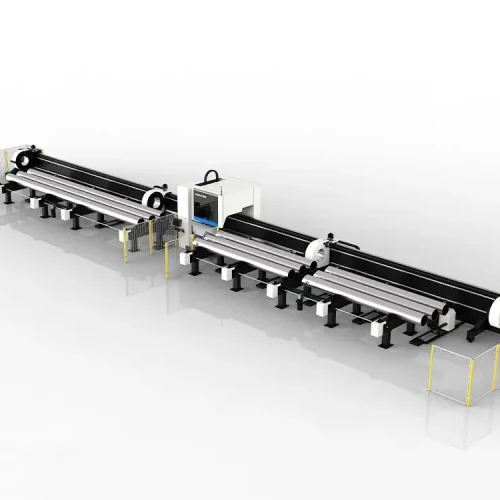

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Rear Chuck

Automatic Oil Lubrication Device

Tube Laser Cutter Benefits

1. Advanced intelligent control systems streamline operations by swiftly generating cutting paths and optimizing processes, significantly enhancing production efficiency.

2. Flexible processing capabilities enable precise cutting of complex geometric shapes and multi-angle designs without additional steps, ensuring greater versatility and adaptability.

3. Equipped with a high-performance fiber laser, the machine delivers exceptional energy efficiency, low power consumption, and consistently superior cutting quality.

4. Delivers precise, stable, and burr-free cuts, ensuring top-notch quality for every product.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.