Tube Laser Cutting Video On Youtube

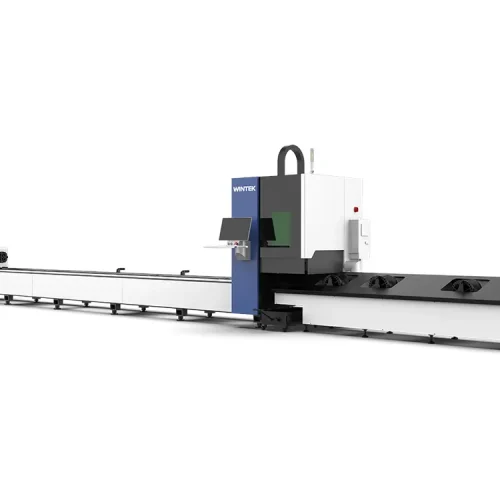

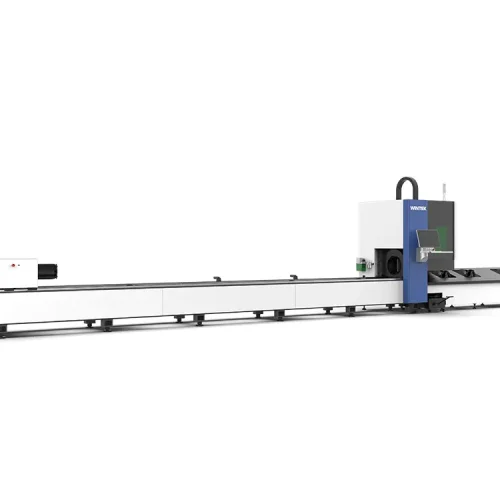

Three-Chuck Pipe Laser Cutting Machine Description

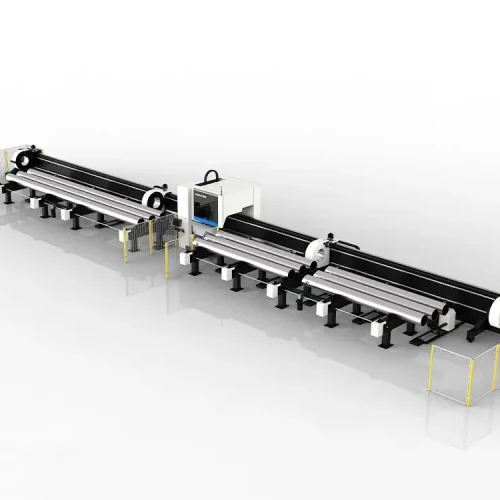

The three-chuck laser tube cutting machine is a high-efficiency, intelligent metal tube processing solution that integrates advanced laser cutting technology with a fully automated loading and unloading system. Its unique three-chuck design ensures precise positioning and stable clamping of various tube shapes, including round, square, rectangular, and irregular tubes, enabling accurate material handling and superior cutting quality. This machine is widely used in industries such as construction, machinery manufacturing, furniture, automotive, and aerospace.

Equipped with a fully automated loading and unloading system, the machine minimizes manual intervention and significantly improves production efficiency. The intelligent control interface allows users to quickly set cutting parameters and program tasks, enabling seamless multi-task cutting operations. The combination of the three-chuck design and a high-performance laser cutting head supports high-speed, high-precision cutting, delivering smooth, burr-free cuts and reducing the need for secondary processing.

Additionally, the three-chuck laser tube cutting machine is compatible with a variety of metal materials, including carbon steel, stainless steel, aluminum alloys, and copper, offering exceptional versatility. The machine features a highly stable structure and advanced auto-focusing technology, ensuring consistent cutting precision and reliability during extended operations. Its efficient dust filtration system and robust safety features provide a productive, safe, and environmentally friendly processing experience.

Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT12028T | WT12035T |

| Max. processing tube length | 12500mm | 12500mm |

| Cutting diameter | 20-280mm | 20-350mm |

| Maximum tube weight | 500kg | 900kg |

| Shortest remaining material | Zero tails | Zero tails |

| Positioning accuracy | 0.05mm | ±0.05mm/m |

| Repositioning accuracy | 0.05mm | ±0.03mm/m |

| Max. Chuck rotating speed | 100r/min | 60r/min |

| Y axis maximum speed | 115m/min | 60m/min |

| X axis maximum acceleration | 1G | 0.6G |

| 20mm roundness | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.40mm | ≤0.40mm |

| Dimensions | 28650*2800*3100mm | 29780*4000*3200 |

Tube Laser Cutting Machine Sample

Machine Configuration

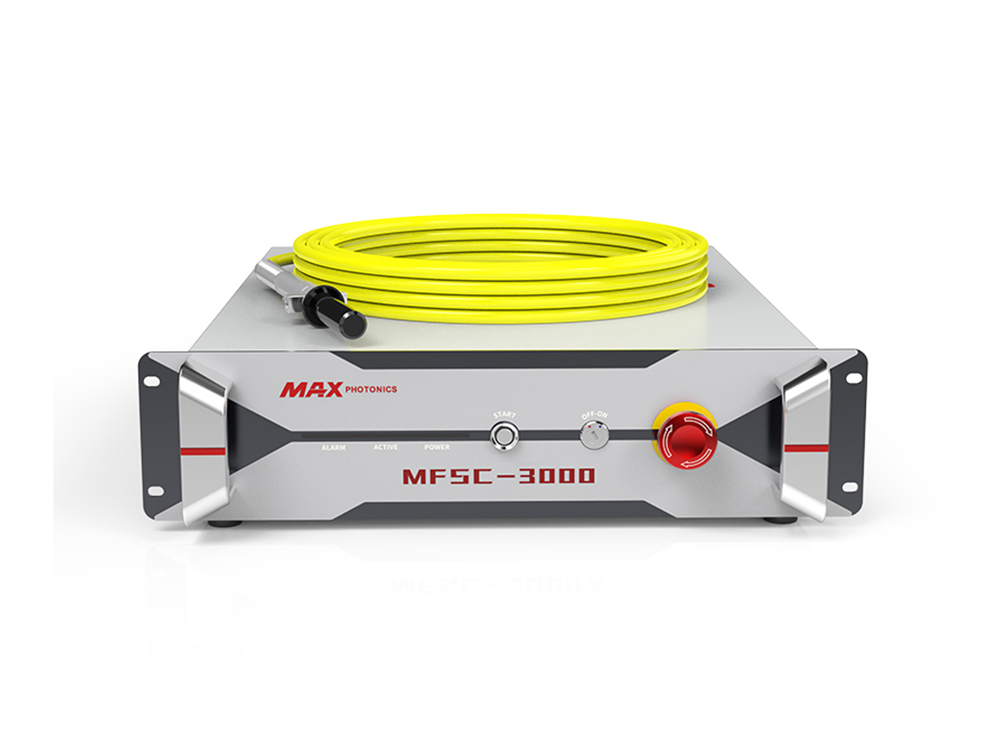

High-Efficiency Laser Source

The machine is equipped with a high-power fiber laser, which offers high energy conversion efficiency and stable beam quality. It enables efficient and precise cutting of various metals such as carbon steel, stainless steel, aluminum alloys, and copper. The laser is designed for continuous operation, ideal for batch processing, and automatically adjusts power output based on material thickness to optimize cutting performance.

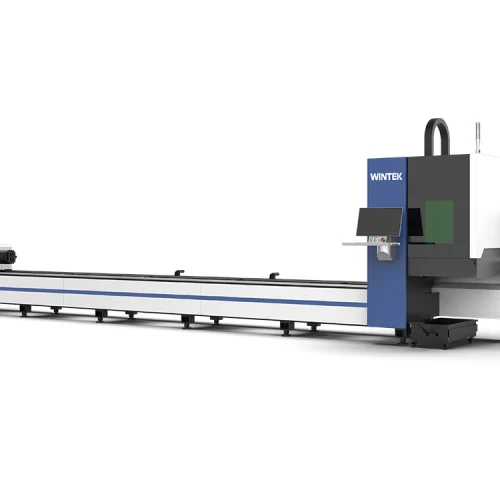

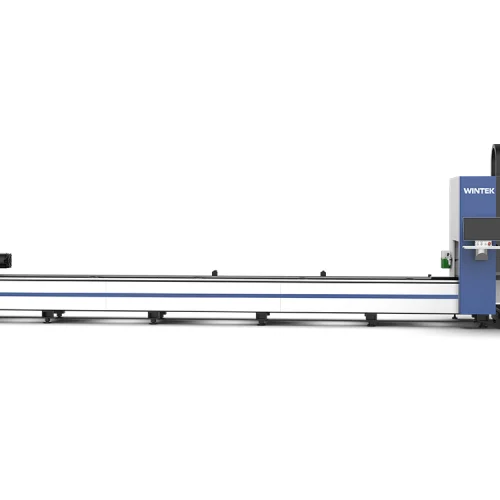

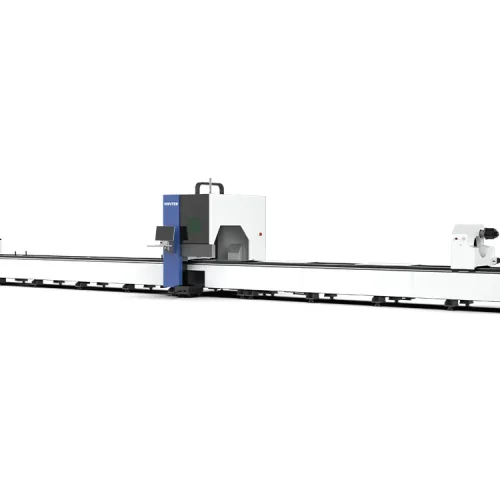

Sturdy And Stable Machine Bed

The bed of the three-chuck laser tube cutting machine is constructed with high-strength steel welded structure, which undergoes multiple heat treatment processes to eliminate internal stresses, ensuring long-term stability and precision during operation. Its heavy-duty design can support long and heavy tubes, preventing vibration or deformation during the cutting process, ensuring high-quality cuts.

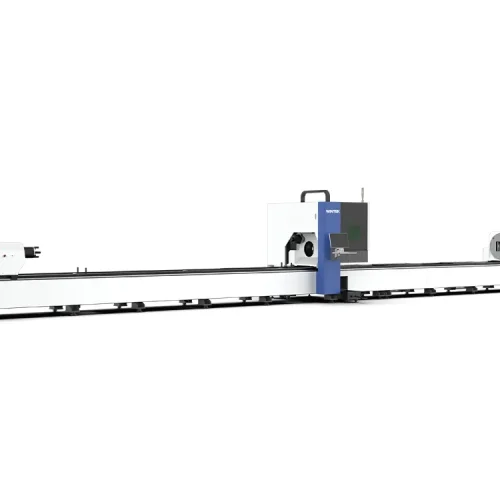

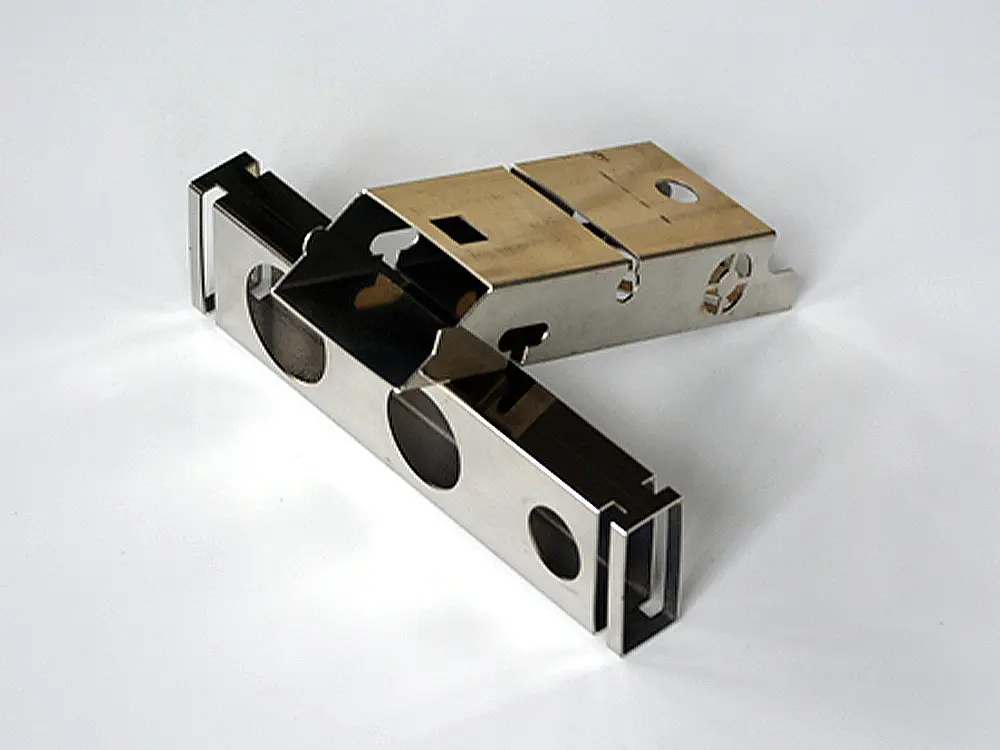

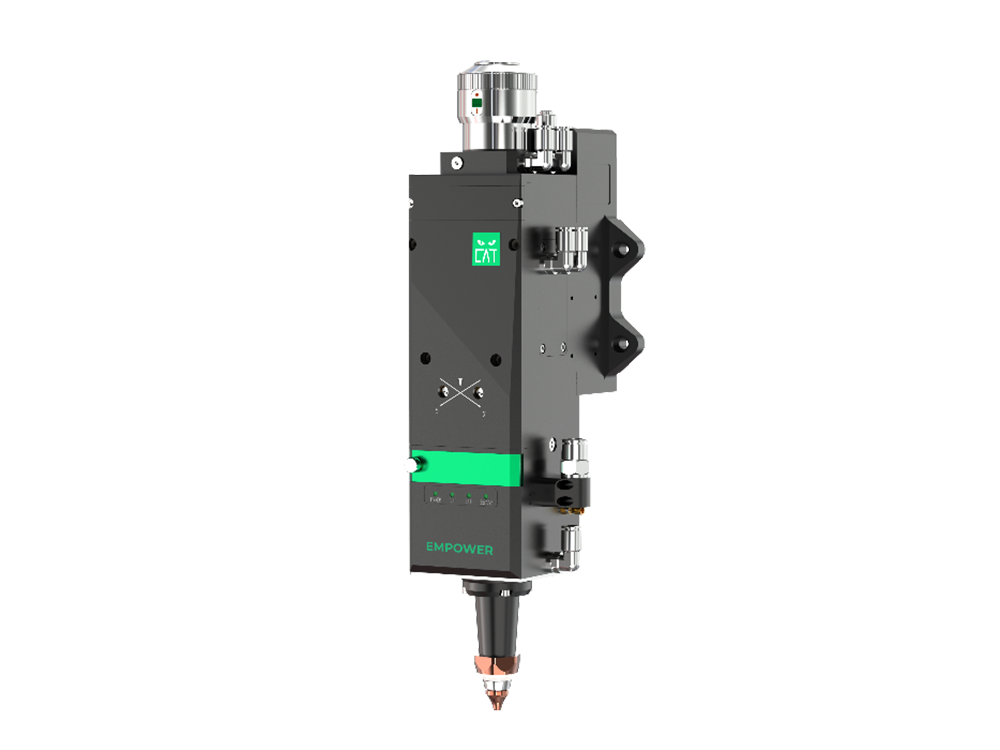

High-Precision 3D Laser Cutting Head

The cutting head adopts automatic focusing technology, which can quickly adjust the focus according to the shape and thickness of the pipe to ensure the best cutting effect. Its optical system is highly precise and stable, with airflow protection to prevent smoke and slag from contaminating the optical components, extending their lifespan. The lightweight design of the cutting head allows for quick response to changes in complex cutting paths, making it suitable for diverse cutting needs.

Tube Laser Cutting System

The machine features an advanced CNC system that supports intelligent operation with a user-friendly interface, making it easy to use. The system allows for quick parameter settings and path planning, with real-time monitoring and alarm functions to ensure safety and efficiency during the cutting process. It also supports remote diagnostics and software upgrades, facilitating maintenance and feature expansion.

Tube Laser Cutting Machine - Other Core Components

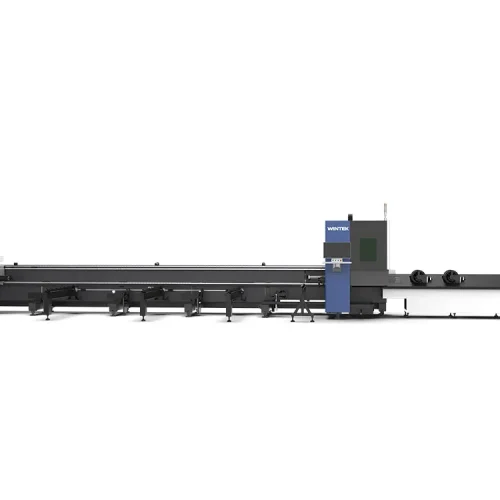

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Automatic Oil Lubrication Device

Water Cooler

Tube Laser Cutter Benefits

1. Three-Chuck Design for Precision and Stability: The unique three-chuck structure ensures precise positioning and stable clamping for round, square, rectangular, and irregular tubes. It minimizes tube deformation and guarantees high-precision cutting, making it ideal for complex shapes.

2. Fully Automated Loading and Unloading for Efficiency: With an automatic material handling system, the machine eliminates the need for manual intervention, streamlining loading, conveying, and unloading. This significantly reduces production cycles and enhances efficiency, especially for large-scale production.

3. High-Performance Laser Cutting for Superior Quality: Equipped with a high-power laser cutting head, it delivers fast cutting speeds and smooth, burr-free edges, reducing the need for secondary processing. Combined with an intelligent CNC system, it supports high-speed and high-precision cutting for diverse applications.

4. Intelligent Operation for Ease and Efficiency: The advanced CNC system enables quick programming and automated path optimization, with a user-friendly interface for easy operation. Real-time monitoring and error detection enhance safety and operational stability.

5. Multi-Material Compatibility for Versatility: Compatible with carbon steel, stainless steel, aluminum alloys, copper, and more, the machine is widely applicable across industries such as construction, automotive, aerospace, and furniture manufacturing.

6. Durability, Environmental Friendliness, and Safety: Built with a robust structure for long-term stability, it features an efficient dust filtration system to minimize environmental impact. Multiple safety mechanisms ensure the protection of operators during use.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.