Tube Laser Cutting Video On Youtube

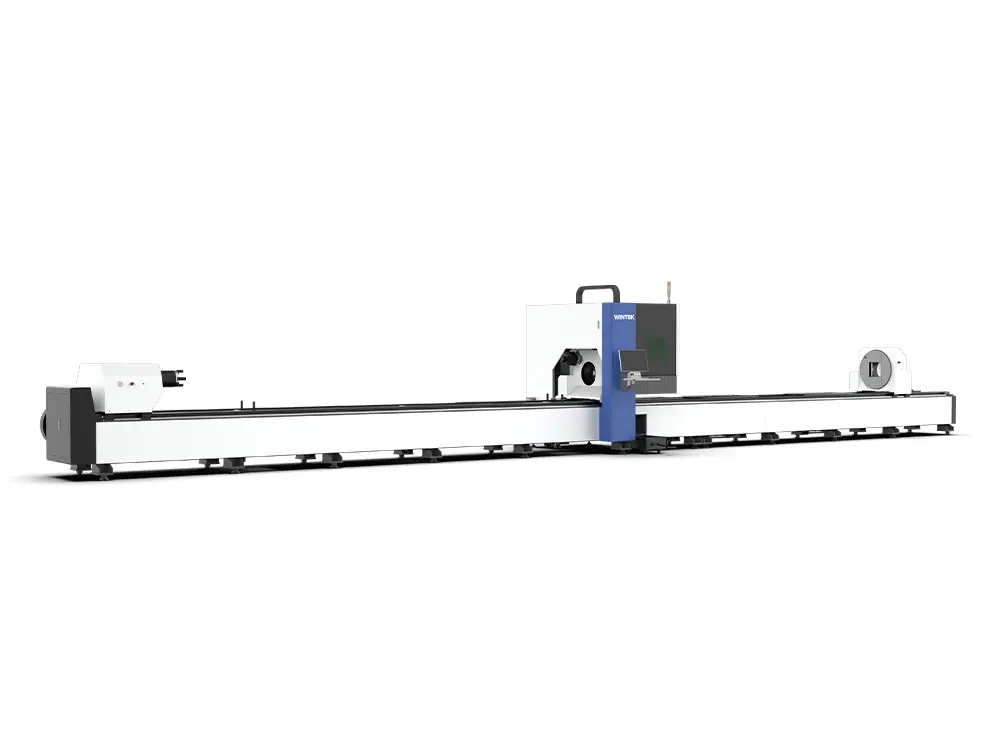

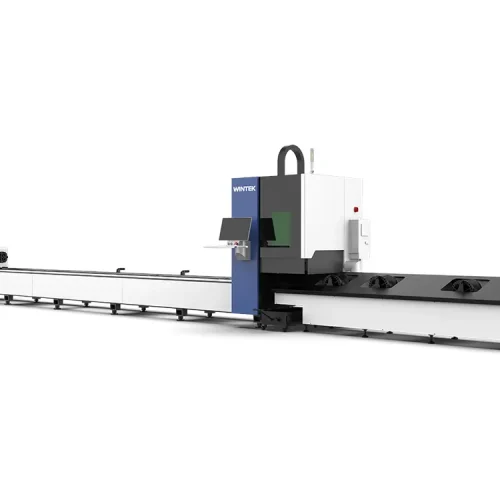

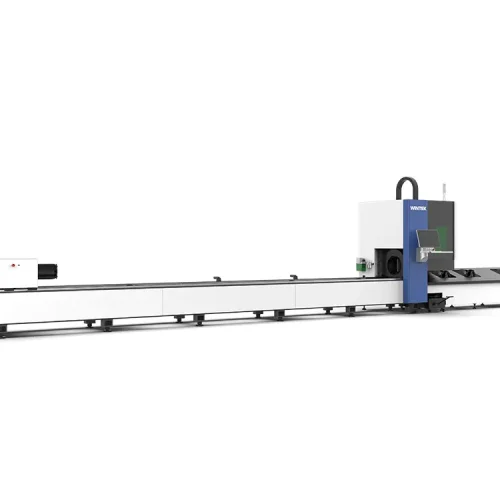

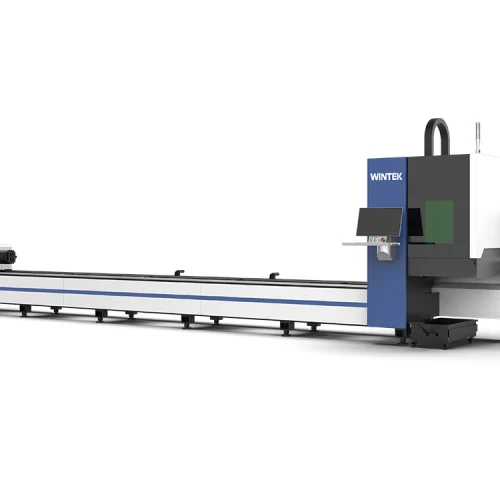

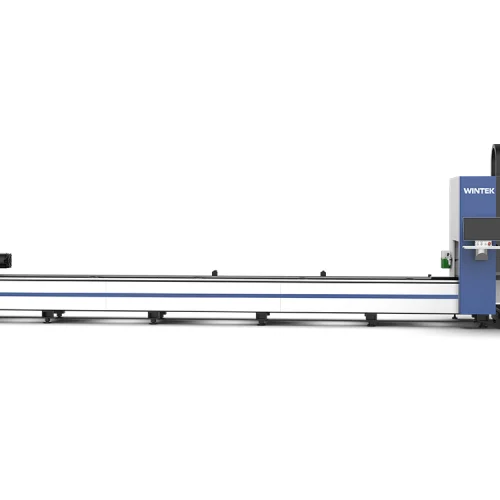

▍Laser Tube Cutting Machine Description

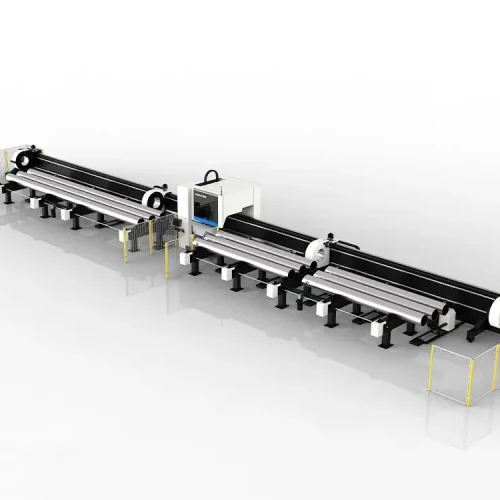

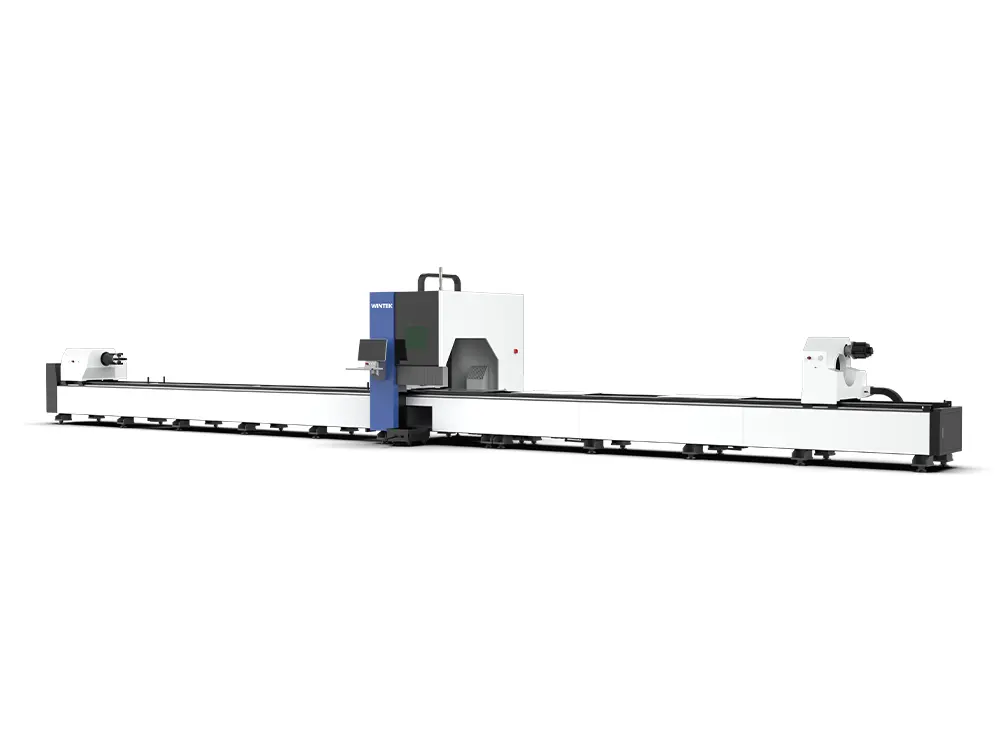

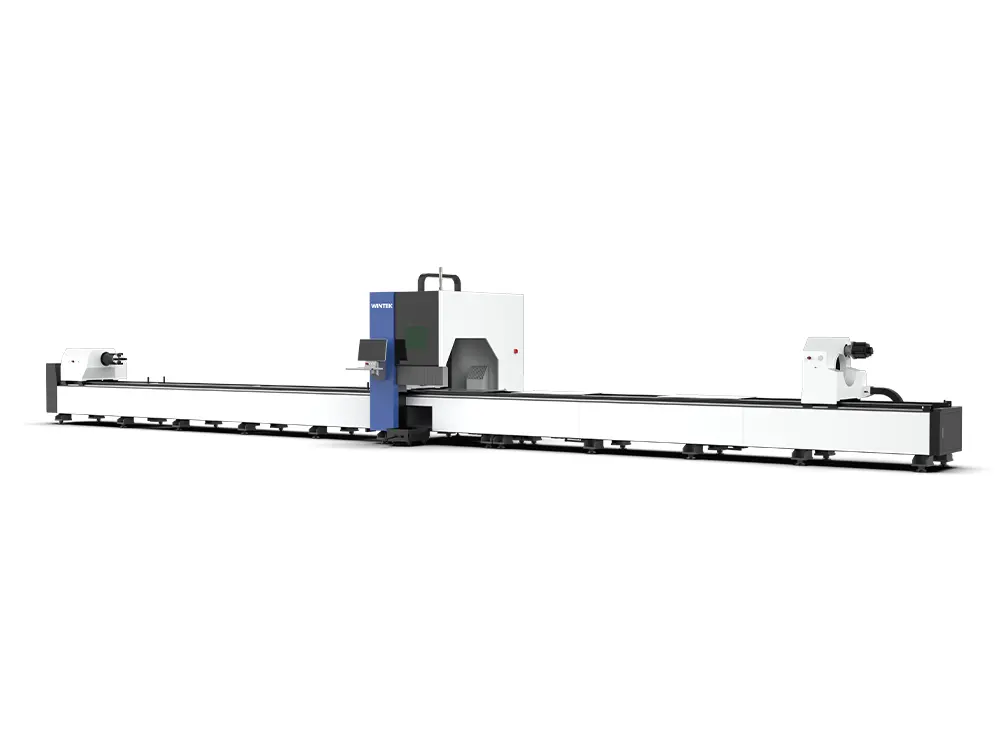

The three-chuck tube laser cutting machine is a high-efficiency, precision processing device designed to meet various metal tube cutting requirements. Its three-chuck structure provides stable clamping for tubes, ensuring cutting accuracy and consistency, whether for long or irregularly shaped tubes.

Equipped with advanced laser cutting technology, the machine delivers smooth, burr-free edges, significantly improving processing quality and efficiency. It allows flexible adjustment of cutting parameters to accommodate different tube materials and specifications, making it an ideal choice for efficient metal processing.

The machine is designed with a user-friendly interface for intuitive operation, enabling quick setup and ease of use. Constructed with high-strength materials, it offers robust stability and reliable long-term performance. This ensures consistent production output while effectively reducing operational costs.

▍Laser Tube Cutting 1KW-12KW Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT6020T | WT12035T |

| Max. Processing Tube Length | 6300mm | 12500mm |

| Cutting Diameter | 20-240mm | 20-350mm |

| Maximum Tube Weight | 300kg | 900kg |

| Positioning Accuracy | ±0.05mm/m | ±0.05mm/m |

| Repositioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| Max. Chuck Rotating Speed | 120r/min | 80r/min |

| Y Axis Maximum Speed | 110m/min | 80m/min |

| X Axis Maximum Acceleration | 1.5G | 0.8G |

| Dimensions | 16800*2730*2300mm | 22780*2900*2460mm |

| Laser Power Range | 1000W-12000W | 1000W-12000W |

| Supported Materials | Carbon Steel, Stainless Steel, Aluminum | Carbon Steel, Stainless Steel, Aluminum |

| Operating Voltage | 380V/50Hz | 380V/50Hz |

▍Laser Tube Cutting Machine Sample

▍Laser Tube Cutting Machine Configuration

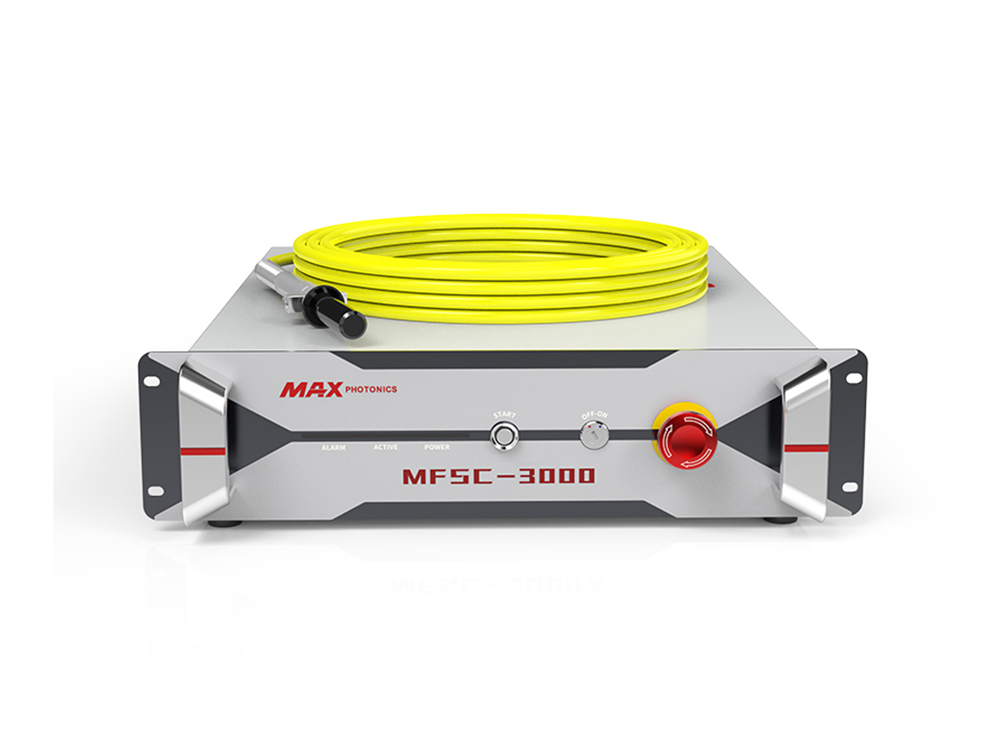

High-Efficiency Laser Source

The machine is equipped with a high-power fiber laser, known for its high energy conversion efficiency and stable beam quality. The fiber laser offers excellent cutting performance, enabling fast, precise cuts in various metal tubes such as stainless steel, carbon steel, and aluminum. It is designed for continuous, high-precision cutting, with automatic power adjustments based on material thickness.

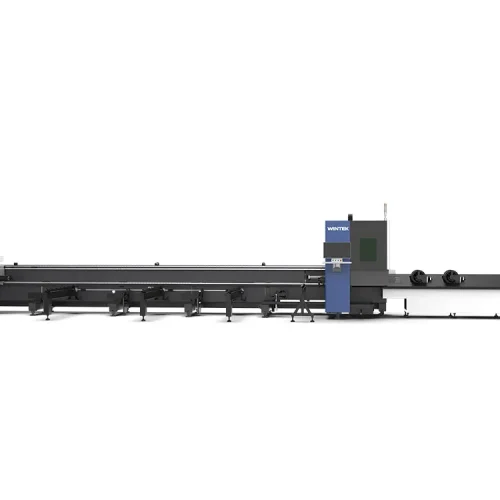

Sturdy And Stable Machine Bed

The bed of the three-chuck tube laser cutting machine is made from high-strength welded steel, which undergoes heat treatment to eliminate internal stresses. This ensures long-term stability and precision during operation. The sturdy bed design reduces vibrations, providing a solid foundation for precise cutting and supporting long or heavy tubes without deformation.

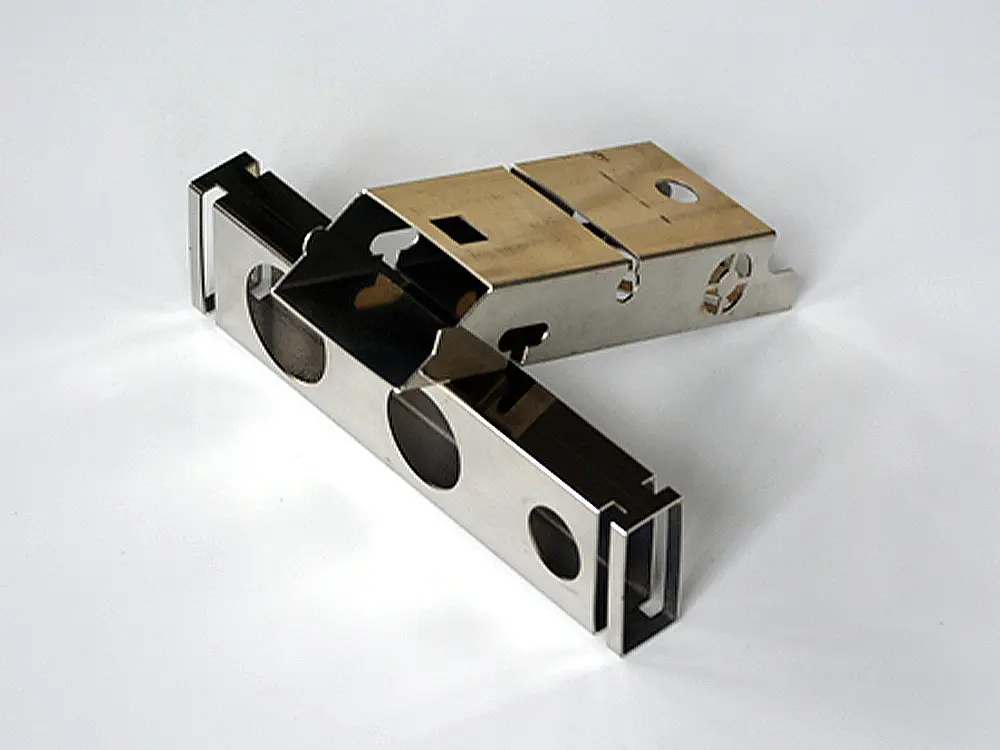

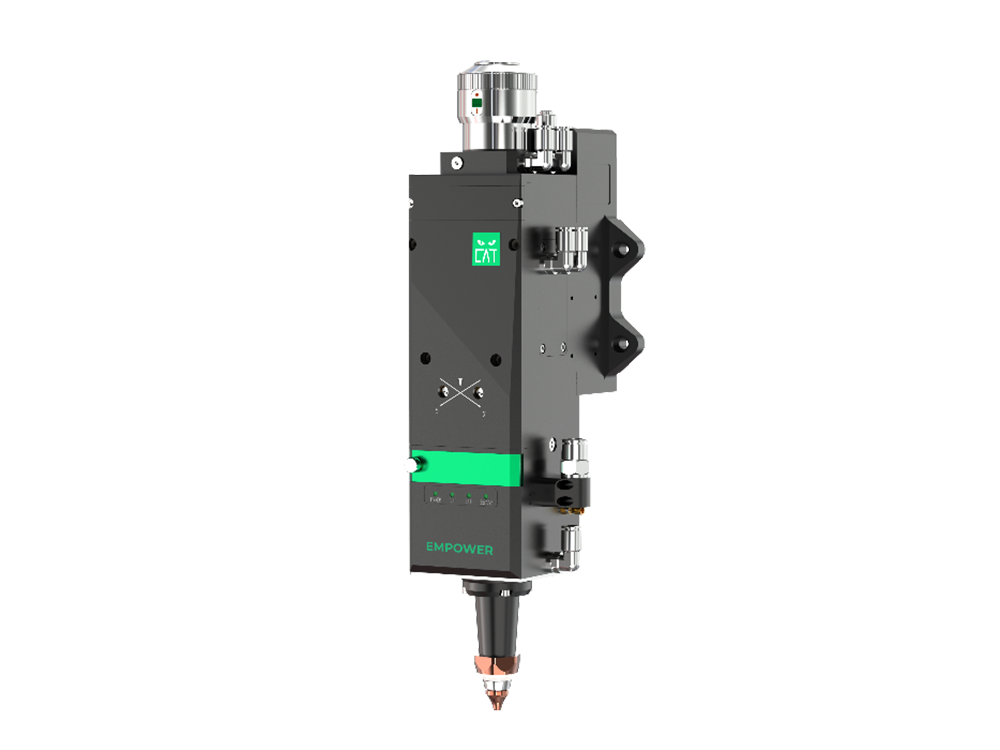

High-Precision 3D Laser Cutting Head

The cutting head features advanced automatic focusing technology, allowing for quick and precise adjustments to the focal length based on tube dimensions and thickness. It also has a high-quality optical system that ensures stable and accurate laser beams. The cutting head is equipped with an airflow protection system, which prevents smoke and slag from contaminating the optical components, extending their lifespan and maintaining cutting quality.

Tube Laser Cutting System

The machine is equipped with an advanced CNC system, providing easy-to-use controls for setting cutting parameters and managing the cutting process. The system allows for real-time monitoring, fault detection, and automatic path optimization, ensuring smooth and efficient operations. It also features a user-friendly interface and remote diagnostics for maintenance, making it easy for operators to manage and troubleshoot.

Tube Laser Cutting Machine - Other Core Components

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Automatic Oil Lubrication Device

Water Cooler

▍Laser Tube Cutting Machine Benefits

1. High Precision Cutting: The three-chuck design ensures stable tube clamping during cutting, providing high precision and consistent results. The laser technology delivers smooth, burr-free cuts, reducing the need for secondary processing.

2. Strong Stability and Wide Compatibility: The machine’s robust structure minimizes vibrations, making it suitable for cutting long tubes, irregularly shaped tubes, and various materials. It operates reliably with different tube specifications and processing requirements.

3. Efficient Production: Equipped with advanced laser cutting technology and an optimized control system, the machine offers fast cutting speeds and high efficiency. Compared to traditional cutting methods, it significantly reduces production time and improves throughput.

4. Labor Cost Savings: The high degree of automation reduces the need for manual labor, especially with the three-chuck design, which minimizes manual adjustments and enhances operational stability and efficiency, leading to cost savings.

5. Easy Operation: The machine features a user-friendly CNC system with an intuitive interface, making it easy to set cutting parameters. It’s easy to operate, requiring minimal training, and is suitable for operators of varying skill levels.

6. Low Maintenance Costs: Built with high-quality components, the machine offers excellent stability and a reduced failure rate, extending the lifespan of the equipment. Additionally, laser cutting technology requires less maintenance compared to traditional cutting methods, leading to lower operational and repair costs.

Contact us now to learn more about our advanced tube laser cutters. Complete the form to receive a customized quote.