Tube Laser Cutting Video On Youtube

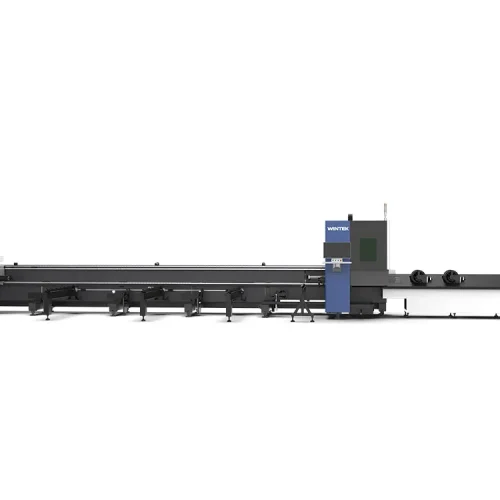

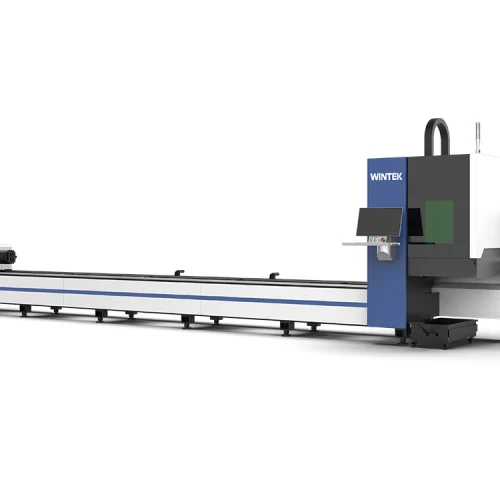

▍Super Heavy Duty Tube Laser Cutting Machine Description

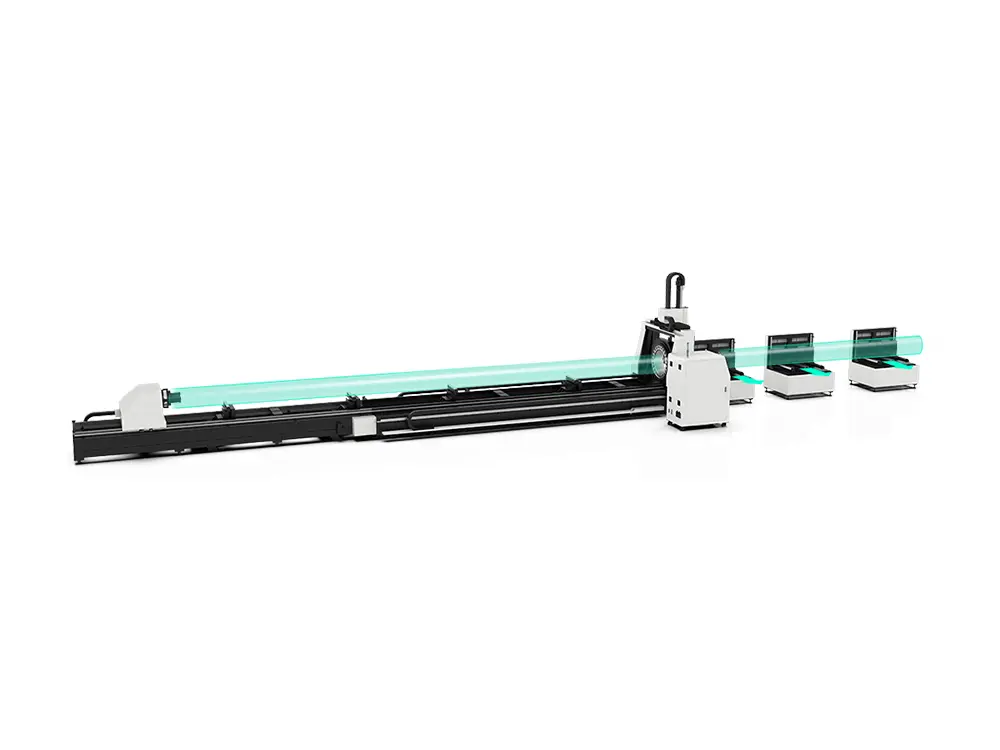

The heavy-duty tube laser cutting machine is a high-performance solution designed for processing oversized and heavy pipes, meeting the demands of complex industrial applications. It supports cutting large diameters and long pipes, making it suitable for various metal materials such as carbon steel, stainless steel, and aluminum alloy. Equipped with a high-power laser, it offers fast cutting speeds, smooth edges, and high precision, significantly improving processing efficiency and reducing the need for secondary finishing.

This machine features a robust and durable structure capable of handling heavy pipes while ensuring long-term stability under high loads. High-precision clamps and an automatic centering system enhance cutting accuracy. With fully automated operations, including automatic loading and unloading, combined with an advanced CNC system and intelligent software support, it enables quick programming and versatile cutting processes, minimizing manual intervention and simplifying operation.

Additionally, the heavy-duty pipe laser cutting machine prioritizes environmental sustainability and safety, featuring an efficient dust filtration system to minimize environmental impact and meet green production standards. Its safety mechanisms ensure operator protection. Widely used in industries such as construction, shipbuilding, oil pipelines, and aerospace, it is an indispensable tool for processing large-scale pipes in modern industrial production.

▍Large Tube Laser Cutting Machine 3KW-20KW Technical Parameters

The tube laser cutting machine is engineered for high-precision and efficient processing of various metal tubes. It offers advanced features to meet the demands of modern industrial applications, ensuring exceptional performance and accuracy. The following is an introduction to the parameters of the fiber laser tube cutting machine:

| Model | WT7069T |

| Round tube processing range | 200-680mm |

| Square tube & rectangular tube processing range | 200-480mm |

| Max. processing tube length | 7300mm |

| Chuck load bearing | 2000kg |

| The tail tube length | 190mm |

| Overall weight | 13000kg |

| Positioning accuracy | ±0.1mm/m |

| Repositioning accuracy | ±0.1mm/m |

| Max. Chuck rotating speed | 26r/min |

| Y axis maximum speed | 60m/min |

| X maximum acceleration | 0.5G |

| Chuck | Full pneumatic self centering chuck |

| Dimensions | 16500*2390*2640mm |

▍Large Tube Laser Cutting Machine Sample

▍Large Tube Laser Cutting Machine Configuration

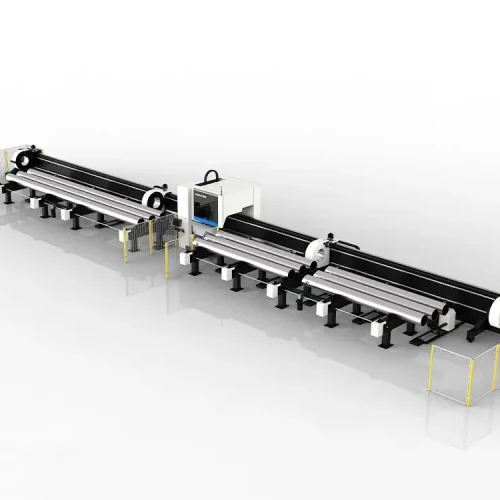

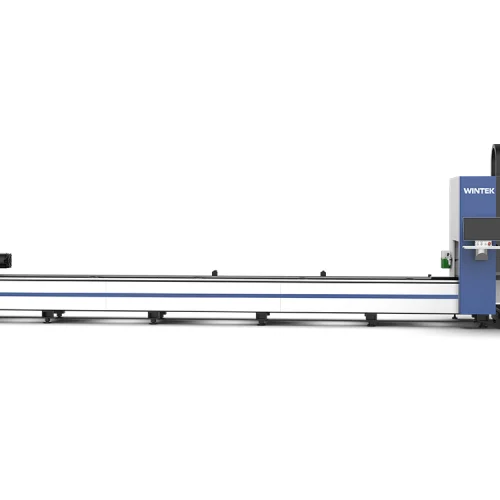

Ultimate Stability

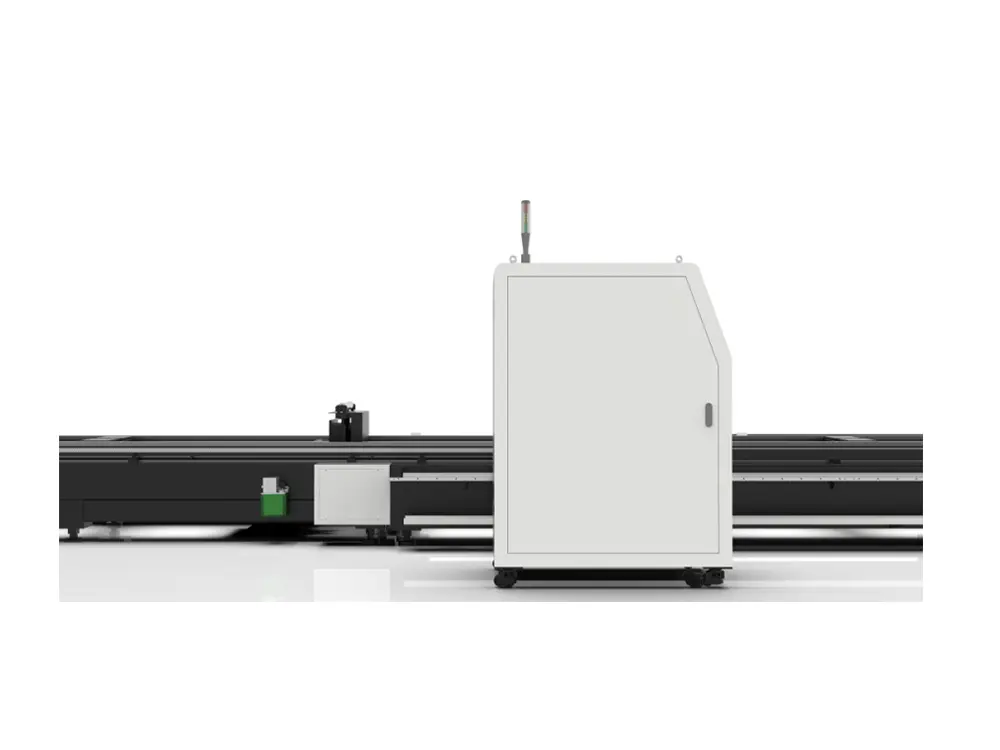

Featuring a horizontal bed layout for a low center of gravity and enhanced structural stability. The extra-long movable gantry allows for the cutting of ultra-long workpieces.

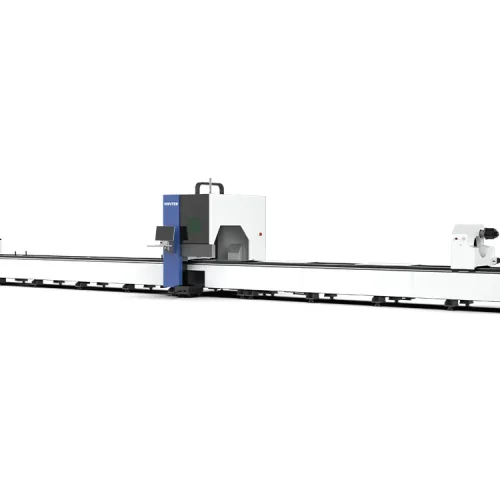

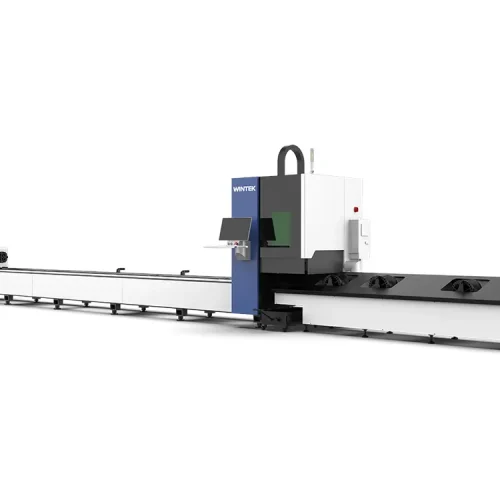

Intelligent Cutting Head

The cutting head usually adopts a high-precision optical system and autofocus technology to ensure that the laser beam is always in the best condition, thus achieving efficient and precise cutting.

Skilled Craftsmanship, Precision in Every Step

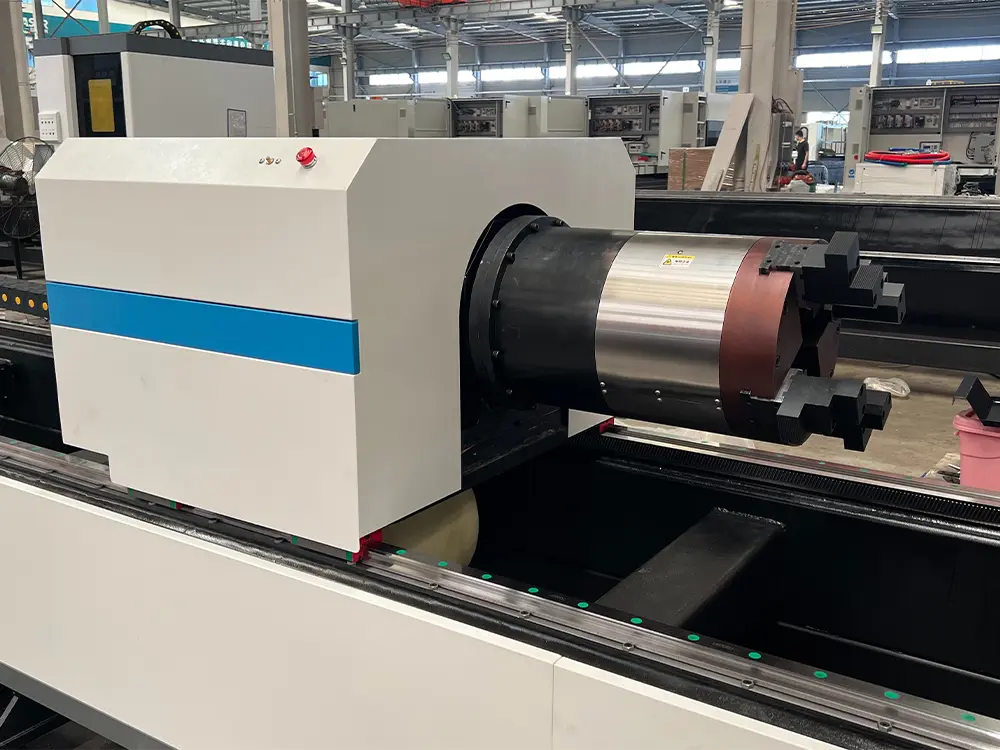

The dual chuck system enables efficient processing, with loading and unloading support devices that effectively secure the pipes, improving cutting accuracy. The optimized cutting action allows for convenient material feeding, increasing production efficiency.

Electrical Separation, More Stable Operation

High-voltage and low-voltage electrical components, along with the pneumatic control units, are separated into independent chambers, ensuring separate transmission and transport. This prevents interference, resulting in more stable operation and more reliable production.

Tube Laser Cutting Machine - Other Core Components

Segmented Automatic Support

Full Automatic Pneumatic Chuck

Rear Chuck

Automatic Oil Lubrication Device

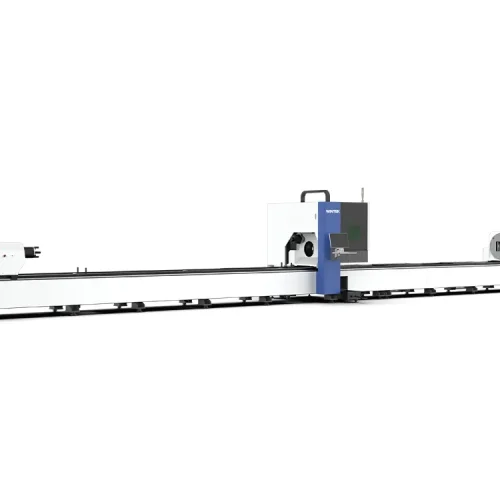

▍Large Tube Laser Cutting Machine Benefits

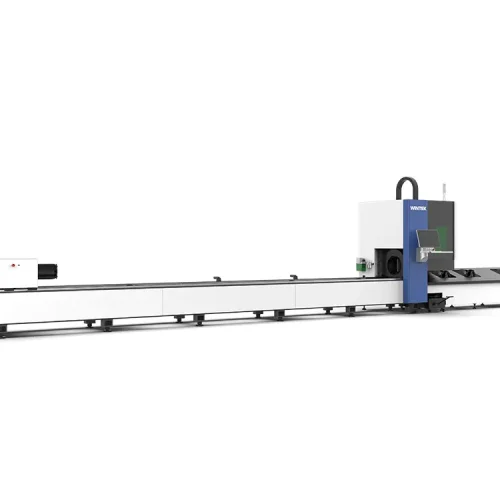

1. Superior Cutting Capacity: It supports cutting large diameters (700mm and above) and long pipes (up to 12 meters), capable of handling heavy-duty pipes. This makes it ideal for large structural components and heavy industrial applications.

2. High Efficiency and Precision: Equipped with a high-power laser, it delivers fast cutting speeds and high efficiency. The cutting surface is smooth, with clean edges, eliminating the need for secondary processing and greatly improving production efficiency.

3. Intelligent and Automated Operations: The advanced CNC system allows for quick programming and complex cutting path design, making it easy to operate. The automatic loading and unloading features reduce manual intervention, increasing production automation.

4. Versatile Cutting Capabilities: It supports various cutting processes, including bevel cutting, hole cutting, and curved cutting, catering to a wide range of industrial needs.

5. Material Compatibility: It is capable of cutting a variety of metal materials, including carbon steel, stainless steel, aluminum alloys, and copper, making it highly versatile.

6. Stability and Durability: The machine’s robust and durable structure ensures stable operation under high loads, maintaining cutting accuracy over time. High-precision clamps and automatic centering devices further enhance processing quality.

Contact us now to learn more about our advanced large tube laser cutters. Complete the form to receive a customized quote.