Laser cleaning technology has emerged as an innovative and eco-friendly cleaning method, gaining widespread attention in industrial sectors. From rust removal on metals to mold cleaning, cultural relic restoration, and coating removal, its applications are diverse and growing. For entrepreneurs, the laser cleaning business presents a lucrative opportunity. In this guide, we will explore how…

When choosing a laser welding machine, the cooling system is a crucial consideration. The choice between water-cooled and air-cooled systems significantly impacts the efficiency, durability, and overall performance of the machine. In this article, we will explore the differences between water-cooled and air-cooled laser welding machines, their respective advantages and disadvantages, and their respective application…

With the rapid popularization of laser cleaning technology, more and more industries are beginning to use laser cleaning machines to seek efficient and environmentally friendly cleaning solutions. Known for their non-destructive cleaning, high efficiency, and low maintenance costs, laser cleaning machines are widely used in aerospace, automotive manufacturing, ship maintenance, cultural heritage restoration, and more….

In modern manufacturing, handheld laser welding machines have become indispensable tools for a wide range of welding tasks, offering unmatched precision, speed, and versatility. Whether you’re working in automotive manufacturing, intricate jewelry design, or industrial maintenance, these machines are revolutionizing the way welding is done. In this article, we present the top 10 best handheld…

Laser paint removal has emerged as a cutting-edge technology for cleaning and restoring surfaces, providing a safer, more precise, and environmentally friendly alternative to traditional methods like chemical stripping and sandblasting. However, safety concerns and questions about its application remain common. This article explores whether laser paint removal is safe, how it works, and what…

Fiber laser welder machines, renowned for their high precision, efficiency, and versatility, have become essential tools in the industrial manufacturing sector. However, many still wonder about their capability to weld materials of varying thicknesses. To address this, Wintek offers a comprehensive overview of the working principles of fiber laser welder machines, explores their maximum welding…

With advancements in industrial cleaning technologies, laser cleaning machines have become the go-to tool for surface treatment due to their efficiency, eco-friendliness, and precision. Among these, continuous laser cleaning machines stand out for their steady and reliable laser output, making them ideal for large-scale and high-efficiency cleaning tasks. Proper operation of a continuous laser cleaning…

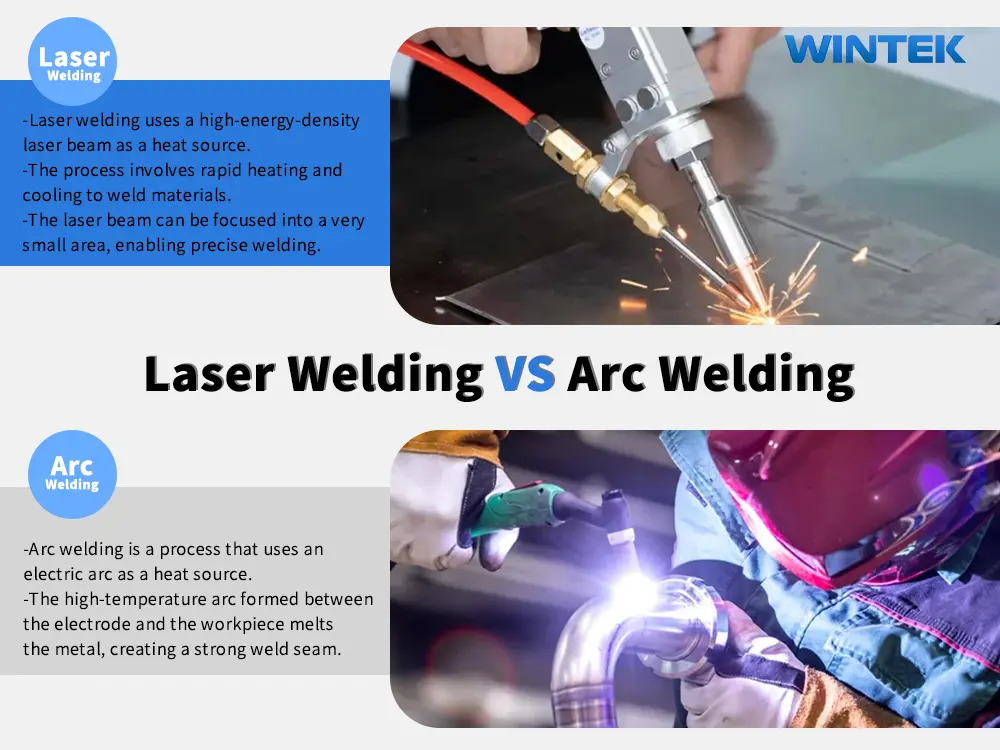

In modern manufacturing, welding technology is an indispensable component. With continuous advancements in technology, welding processes have become increasingly diverse. Among these, arc welding and laser welding are the two most common methods, each with distinct characteristics and advantages suitable for different applications. In this article, we will delve into the key differences between arc…

In recent years, fiber laser cleaning technology has gained popularity in various industries due to its high efficiency, eco-friendliness, and non-contact nature. It is widely used in fields such as manufacturing, shipbuilding, and precision maintenance. However, with numerous brands and models available on the market, choosing the right fiber laser cleaning machine can be challenging….

In modern industry, metal processing plays an indispensable role, with efficiency and precision being key benchmarks for evaluating processing technologies. The emergence of the 3 in 1 laser machine has brought an innovative solution to metal processing by combining welding, cutting, and cleaning functions into a single device. This 3 in 1 laser welding cleaning…