Introduction

Fiber laser welding is a new generation of laser welding equipment. This non-contact welding method does not require pressurization during operation. Its working principle is to directly irradiate a high-energy laser beam onto the surface of the material. Through the interaction between the laser and the material, the material is melted inside and then cooled and crystallized to form a weld.

The heat-affected zone during handheld fiber laser welding is small, and will not cause deformation, blackening, or marks on the back of the workpiece. In addition, the welding depth is large and the welding is firm. It can not only realize thermal conduction welding, but also continuous deep melting welding, spot welding, butt welding, lap welding, sealing welding, seam welding, etc. This process subverts the working mode of traditional laser welding machines and has the advantages of simple operation, beautiful welds, fast welding speed, and no consumables.

Key Components for Fiber Laser Welding

It mainly consists of a laser, welding system, handheld laser gun, wire feeder, and cooling system.

-

Fiber Laser

Fiber laser is usually compact, small, and light in weight. The beam output is stable, and the performance is not easily affected by environmental changes, which can maintain stable welding quality for a long time.

The conversion efficiency of fiber lasers is very high, usually reaching over 30%. You can use it to weld a variety of materials, including stainless steel, carbon steel, aluminum, copper, and other metal materials.

- Laser Welding System

This is the brain of the welding system, controlling the parameters such as laser power, pulse duration, welding speed, and positioning.

-

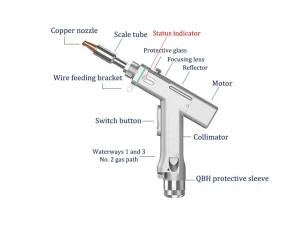

Handheld Laser Gun

The laser welding head uses QBH fiber optic handheld laser welding head.

Its features are as follows:

1. The unique laser control box has three light output modes: QCW (quasi-continuous), PWM (pulse), and CW (continuous).

2. It adopts ergonomic design, compact structure, and easy to use.

3. The welding head is equipped with air blowing control and safety lock.

Gun head nozzle: You can replace the appropriate nozzle according to different angles. It can make the welding surface more integrated and smoother.

Inlet and outlet: Two 6mm inlets and outlets, to ensure that the focusing mirror inside the gun body is at a certain temperature to make the welding effect more stable.

QBH connector: a special connector for lasers. Non-professionals are prohibited from disassembling.

-

Wire Feeder

The wire feeder of a fiber laser welding machine can usually adapt to various types of welding wires, such as welding wires of different materials such as stainless steel, aluminum alloy, copper alloy, and even welding wires of different diameters (usually between 0.8mm and 2.0mm). In addition, the wire feeder can accurately control the feeding speed of the welding wire to ensure that the welding wire supply during the welding process matches the laser power and welding speed.

-

Water Cooling System

Modern water chillers are usually compact in design, small in size and light in weight, making them easy to integrate into the fiber laser welding system. This makes the entire welding equipment easier to install and maintain.

The water chiller equips a precise temperature control system that monitors and adjusts the water temperature in real-time, ensuring the cooling water stays within the appropriate range.

How Does Fiber Laser Welding Work?

The process of fiber laser welding machine involves several key steps to ensure a high-quality weld. Here are the steps for fiber laser welding:

1. Preparation of Materials

Place the workpiece to be welded accurately on the workbench and fix it with a clamp to keep it stable. For workpieces with complex shapes or curved surfaces, auxiliary tools can be used for precise positioning.

2. Setup and Calibration

The operator sets the appropriate laser power, pulse duration, and frequency based on the material, thickness, and type of weld required. Adjust the optical path so that the laser beam focus falls precisely at the welding starting position.

3. Start Welding

After pressing the start button, perform the welding task according to the preset parameters. During this process, keep a close watch and be ready to respond to emergencies at any time. If any abnormal phenomenon is found (such as sparks flying or excessive smoke), stop the operation immediately and find out the cause.

4. End of welding

After welding is completed, turn off the laser output and wait for the molten pool to cool completely. Then remove the workpiece and check the weld quality.

Advantages of Fiber Laser Welding Machine

1. Wide welding range: The handheld welding head is equipped with 10m-20m original optical fiber, which overcomes the limitations of the workbench space and can be used for outdoor welding and long-distance welding.

2. Easy and flexible to use: The handheld laser welding has a mobile pulley, making it comfortable to hold, free, flexible, and suitable for various working environments.

3. Multiple welding methods: Welding at any angle can be achieved, such as lap welding, butt welding, vertical welding, flat fillet welding, internal fillet welding, external fillet welding, etc.

4. Good welding effect: Handheld laser welding is hot melt welding. Compared with traditional welding, laser welding has higher energy density and can achieve better welding effect. The welding area is less affected by heat, is not easy to deform, has a large welding depth, and is firm and reliable.

5. No need to grind the weld: After traditional welding, the weld needs to be polished to ensure it is smooth and free of roughness. However, handheld laser welding has more advantages in processing effect, with continuous and smooth welding, beautiful and scar-free, and less subsequent grinding process.

Conclusion

Fiber laser welding provides an efficient, precise solution, ideal for industries like automotive, aerospace, and electronics. It offers significant advantages over traditional methods, including high energy density, minimal heat-affected zone, and the ability to weld various materials and thicknesses. Flexibility, speed and low maintenance requirements further enhance its appeal for small and medium-sized manufacturing.