Product Description

Technical Parameters

| Type | Nominal pressure (KN) | Workbench length (mm) | Workbench width (mm) | Poles distance (mm) | Throat depth (mm) | Main motor (kw) | Dimensions L*W*H (mm) |

| 40*1600 | 400 | 1600 | 900 | 1165 | 350 | 5.5 | 2250*1650*2400 |

| 63*2500 | 630 | 2500 | 900 | 1960 | 380 | 5.5 | 3150*1700*2500 |

| 80*2500 | 800 | 2500 | 900 | 1960 | 380 | 7.5 | 3150*1700*2500 |

| 80*3200 | 800 | 3200 | 900 | 2760 | 380 | 7.5 | 3850*1700*2500 |

| 100*3200 | 1000 | 3200 | 950 | 2750 | 390 | 7.5 | 3900*1800*2650 |

| 125*3200 | 1250 | 3200 | 950 | 2750 | 390 | 11 | 3900*1800*2680 |

| 160*3200 | 1600 | 3200 | 1000 | 2740 | 400 | 15 | 4000*1900*2720 |

| 200*3200 | 2000 | 3200 | 1000 | 2730 | 400 | 18.5 | 4000*1900*2720 |

| 300*3200 | 3000 | 3200 | 1330 | 2720 | 500 | 22 | 4000*2200*3500 |

| 100*4000 | 1000 | 4000 | 950 | 3350 | 390 | 7.5 | 4800*1800*2650 |

| 125*4000 | 1250 | 4000 | 950 | 3350 | 390 | 11 | 4800*1800*2680 |

| 160*4000 | 1600 | 4000 | 1000 | 3340 | 400 | 15 | 4800*1900*2720 |

| 200*4000 | 2000 | 4000 | 1000 | 3330 | 400 | 18.5 | 4800*1900*2800 |

| 250*4000 | 2500 | 4000 | 1000 | 3330 | 450 | 18.5 | 4800*1900*2850 |

| 300*4000 | 3000 | 4000 | 1330 | 4920 | 500 | 22 | 4800*1950*2900 |

| 200*6000 | 2000 | 6000 | 1000 | 4940 | 400 | 18.5 | 6800*1900*2800 |

| 250*6000 | 2500 | 6000 | 1050 | 4930 | 450 | 18.5 | 6800*1900*2850 |

| 300*6000 | 3000 | 6000 | 1330 | 4920 | 500 | 22 | 6800*1950*2900 |

| 400*6000 | 4000 | 6000 | 1350 | 4920 | 500 | 37 | 6800*2000*2950 |

| 500*6000 | 5000 | 6000 | 1350 | 4910 | 500 | 45 | 6800*2050*3000 |

Press Brake Machine Details

Delem System

Delem DA53T is an advanced CNC system for CNC bending machines, mainly used in sheet metal processing. It uses a high-resolution 11-inch touchscreen and supports 2D graphic programming and simulation. Supports 4+1 axes, 5+1 axes, suitable for complex workpiece processing.

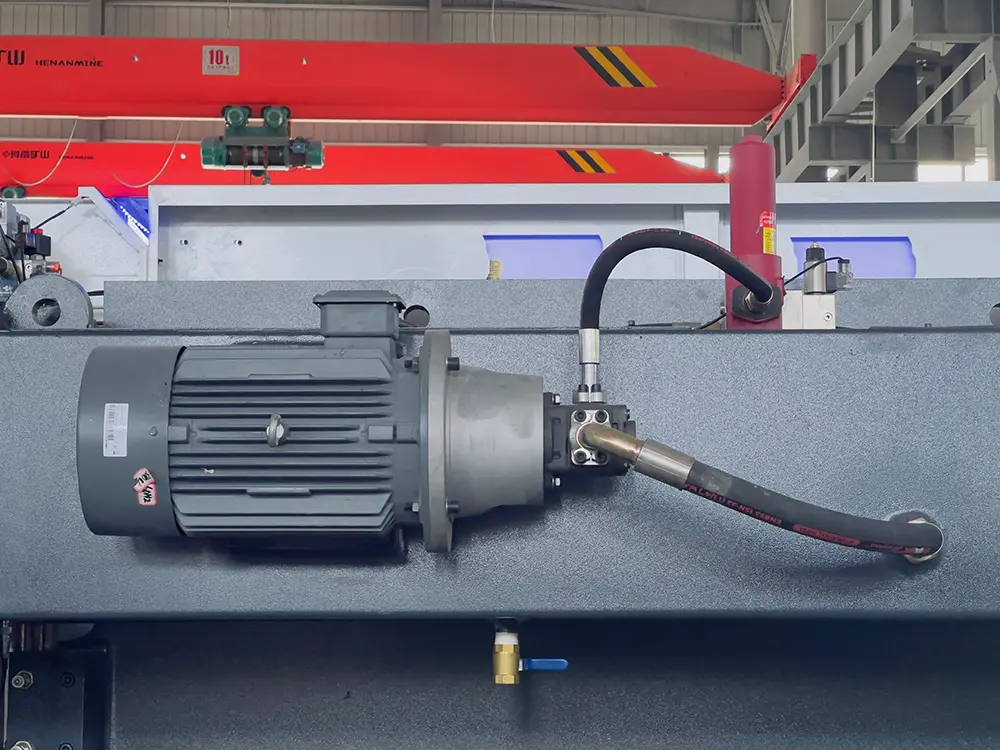

Oil Pump

The oil pump of the bending machine is a key component of the hydraulic system of the bending machine, providing power and pressure for the operation of the bending machine. The product has the advantages of simple structure, good processability, light weight and long service life.

Frame Rigidity Enhancement Treatment

High-precision large gantry machine centers process the frame components, while automatic welding enhances welding uniformity. In addition, vibration aging technology eliminates residual stress after welding, ensuring the durability and stability of the frame.

Dual Hydraulic Cylinders

The strength and rigidity of the hydraulic cylinders located on both sides of the column directly determine the operation accuracy, the service life of the machine tool and the accuracy of the workpiece.

Mobile Front Pallet

The mobile front pallet supports workpiece during the bending process with adjustable height, tilt, and angle to fit various sizes and requirements. It ensures precision and stability, allowing safe removal of the finished workpiece for further processing.

Quick Clamp

The quick clamp of the hydraulic bending machine is used to firmly fix the metal plate or workpiece on the bed or lower die to ensure accurate and precise bending.

Press Brake Punches and Dies

Selecting the right press brake punches and dies is essential before making your purchase. Proper punch and die pairing is crucial for achieving the desired bend shape. We offer a wide range of tooling options tailored to meet diverse bending requirements.