Product Description

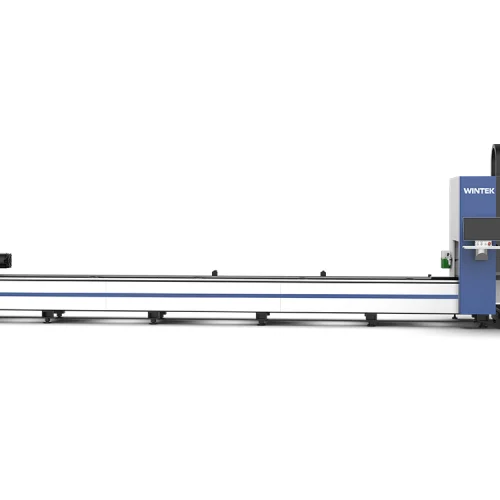

The tube laser cutting machine can achieve high-precision cutting with a small cutting gap and an accuracy of up to ±0.1mm, which is suitable for complex and precise tube cutting.

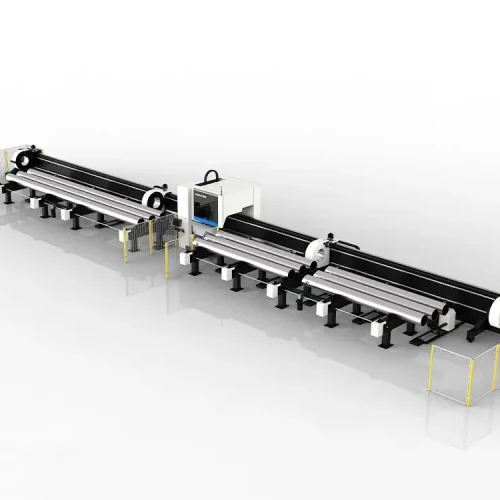

The cutting diameter is 20-120mm, 20-170mm, 20-240mm, and 20-350mm. It can process very large diameter tubes, and the chuck rotates at high speed to improve processing efficiency.

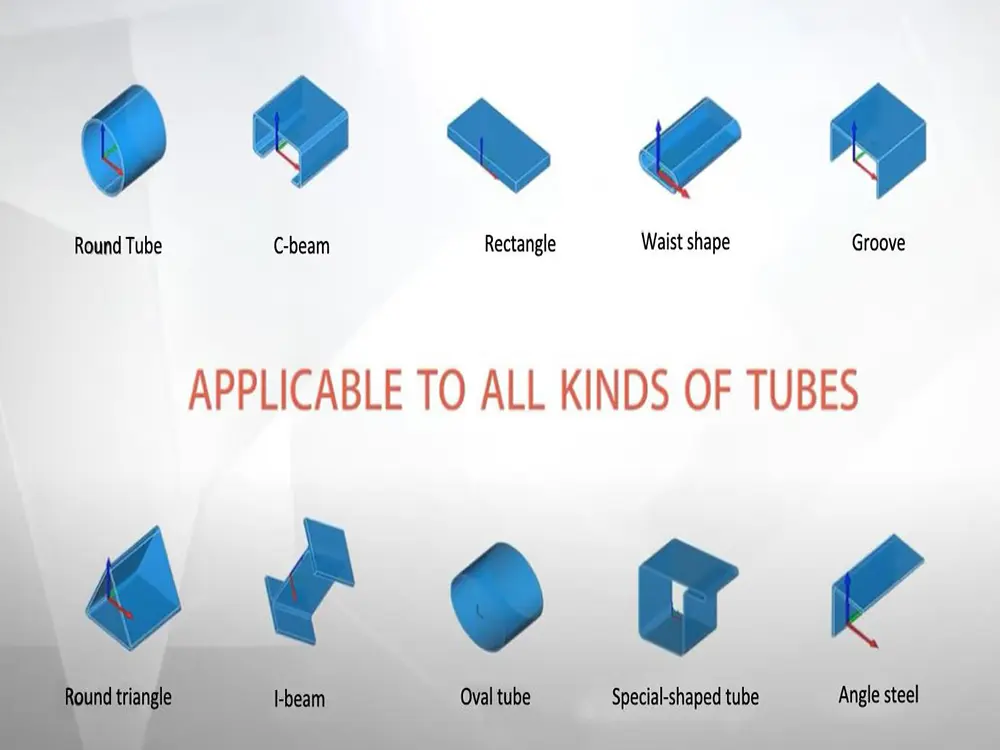

It is suitable for tubes of various shapes, such as rectangular tubes, square tubes, round tubes, I-beams, special shapes, etc.

The laser tube cutting machine is equipped with intelligent software that can automatically generate cutting paths, optimize the cutting process, and reduce processing time.

Sample Show

Tube Laser Cutting Video On Youtube

Technical Parameters

| Item | WT6012T | WT6016T | WT6020T | WT6035T |

| Max. processing tube length | 6300mm | 6300mm | 6300mm | 6300mm |

| Cutting diameter | 20-120mm | 20-160mm | 20-240mm | 0-350mm |

| Maximum tube weight | 100kg | 150kg | 300kg | 900kg |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck rotating speed | 200r/min | 120r/min | 120r/min | 80r/min |

| Y axis maximum speed | 130m/min | 130m/min | 110m/min | 80m/min |

| X axis maximum acceleration | 1.5G | 1.5G | 1.5G | 0.8G |

| 20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.3mm | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| Dimensions | 8750*1490*2210mm | 8870*1550*2150mm | 8870*1500*2220mm | 9280*1720*2300mm |

Details Introduction

Intelligent Cutting Head

The cutting heads are designed for high-precision and efficient laser cutting. They offer stable performance with precise focus control, ensuring clean cuts and minimal material waste. Their advanced cooling systems improve durability, while the robust construction withstands harsh industrial conditions.

Reliable Laser Source

MAX / Raycus lasers offer high efficiency, precision, and stability, making them ideal for various cutting and welding applications. With advanced technology, they ensure superior beam quality, low maintenance, and energy savings, providing cost-effective solutions for industrial operations.

Tube Cutting System

The system adopts high-response servo control to ensure a smooth and accurate cutting trajectory with an error control within ±0.1mm. The system has an anti-shake control algorithm to reduce vibration during high-speed cutting and improve the quality of the finished product.

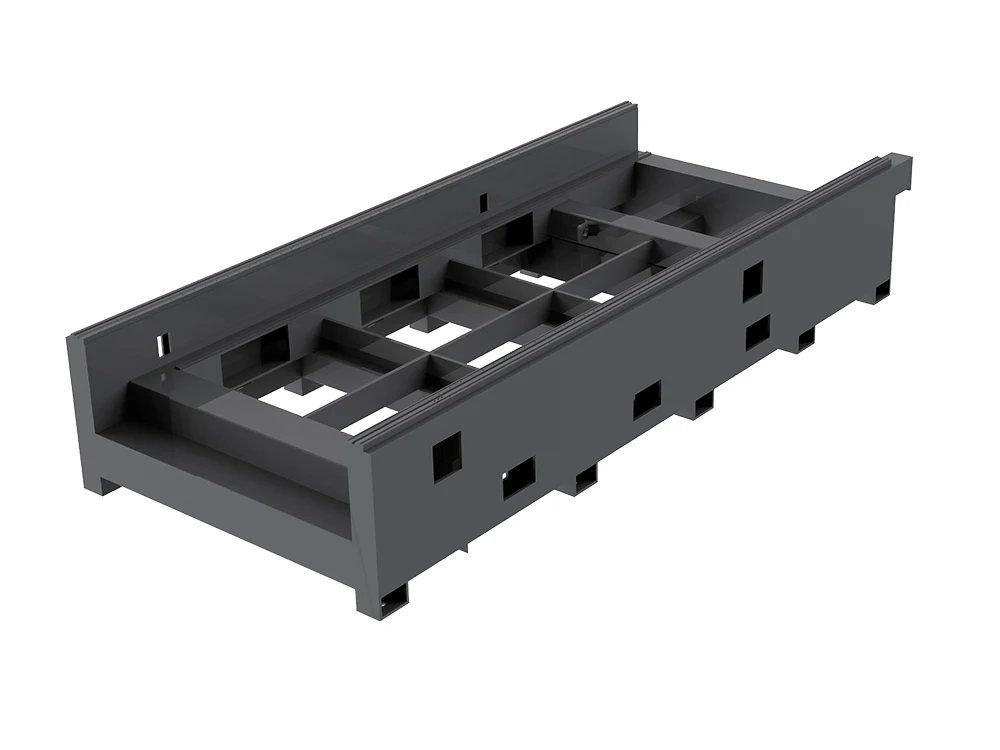

Sturdy And Stable Machine Bed

The bed material offers excellent thermal expansion resistance, preventing deformation in high-temperature environments. It features anti-corrosion, oxidation, and wear-resistant treatments, extending its lifespan. The design ensures quick thermal stability, minimizing the impact of temperature fluctuations on cutting quality.

Cutting Diameter

The cutting diameter of round and square tubes is available from 20mm-120mm/20mm-160mm/20mm-240mm/20mm-350mm

Nesting Software

The nesting software is compatible with the cutting of various pipe materials such as round pipes, square pipes, rectangular pipes, oval pipes, H-shaped steel, channel steel, angle steel, etc. It is suitable for various materials such as stainless steel, carbon steel, aluminum alloy, copper, etc.

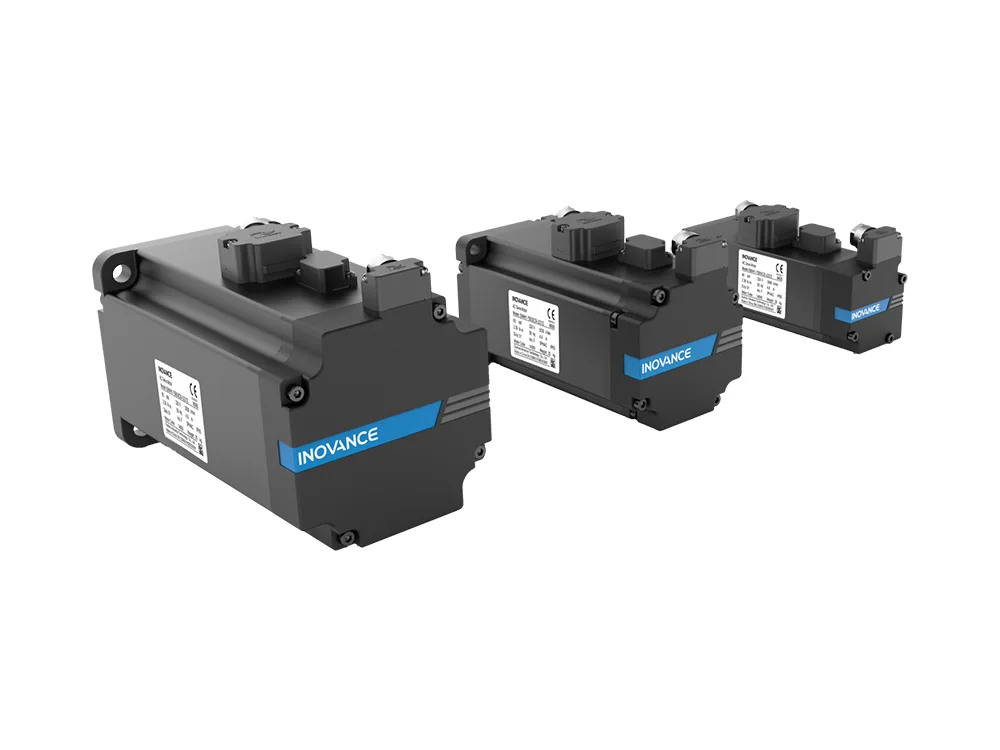

Import Servo Motor

Optimized control algorithm, reduced mechanical vibration, and improved processing quality. The new design reduces energy consumption by 20% compared with the previous generation and extends the motor’s service life.