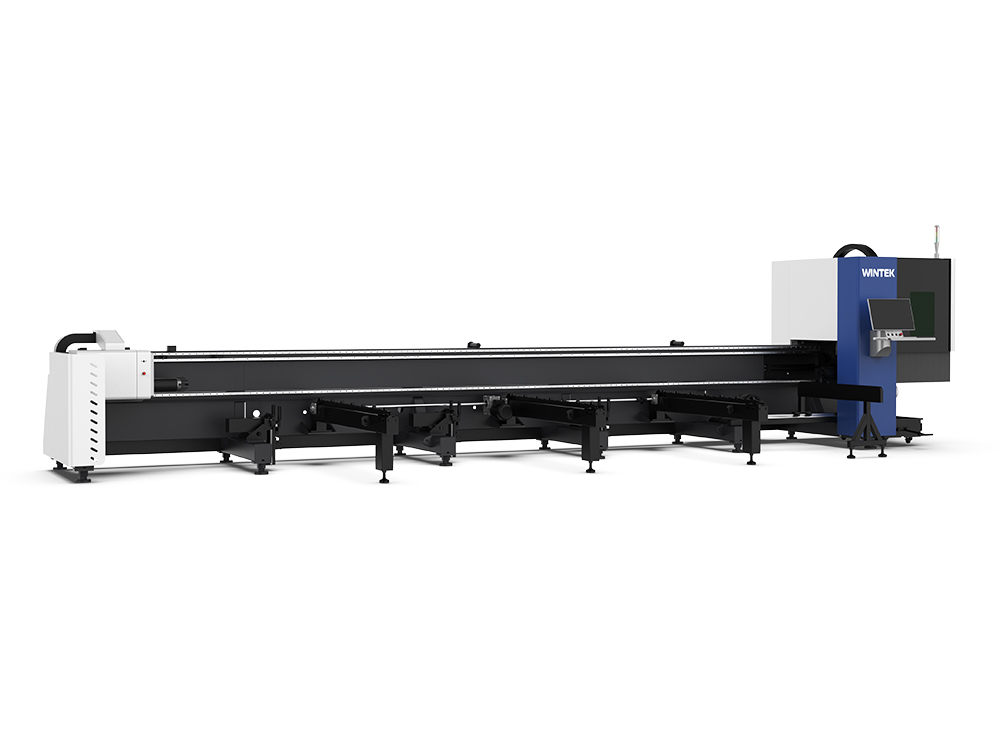

Product Description

WINTEK semi-automatic pipe feeder cutting machine is designed to streamline pipe cutting processes with improved precision and efficiency. It features a user-friendly interface, allowing operators to easily load pipes and adjust cutting parameters.

The machine supports a wide range of pipe sizes and materials, making it highly versatile for various industrial applications.

Its automatic feeding system reduces manual handling, increasing production speed while maintaining consistent cutting quality. With low maintenance and durable construction, it provides a cost-effective and reliable solution for high-volume manufacturing environments.

Sample Show

Tube Laser Cutting Video On Youtube

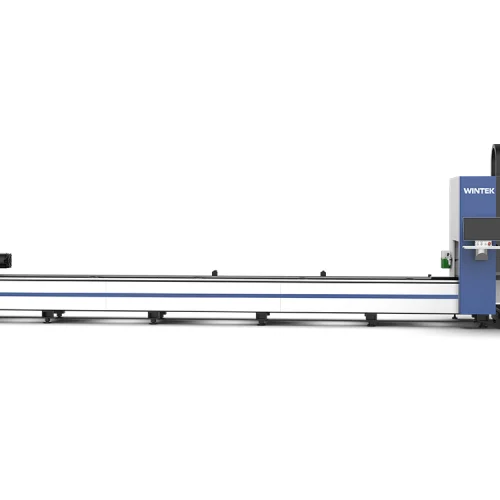

Technical Parameters

| Item | WT6012T – Semi | WT6016T- Semi | WT6020T- Semi | WT6035T- Semi |

| Max. processing tube length | 6300mm | 6300mm | 6300mm | 6300mm |

| Cutting diameter | 20-120mm | 20-160mm | 20-240mm | 0-350mm |

| Maximum tube weight | 100kg | 150kg | 300kg | 900kg |

| Positioning accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| Repositioning accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Max. Chuck rotating speed | 200r/min | 120r/min | 120r/min | 80r/min |

| Y axis maximum speed | 130m/min | 130m/min | 110m/min | 80m/min |

| X axis maximum acceleration | 1.5G | 1.5G | 1.5G | 0.8G |

| 20mm roundness | ≤0.15mm | ≤0.15mm | ≤0.15mm | ≤0.15mm |

| 20mm square diagonal size difference | ≤0.20mm | ≤0.20mm | ≤0.20mm | ≤0.20mm |

| 20mm square position size difference | ≤0.3mm | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| Dimensions | 8750*1490*2210mm | 8870*1550*2150mm | 8870*1500*2220mm | 9280*1720*2300mm |

Details Introduction

Automatic Loading Device

The automatic loading device automatically completes the delivery and initial positioning of the pipe, greatly reducing the time of manual loading. It can reduce the need for operators to directly handle and fix the pipe, reducing the burden of physical labor. Especially for large diameter or heavy pipes, loading is easier and safer.

Reliable Laser Source

Lasers offer high efficiency, precision, and stability, making them ideal for various cutting and welding applications. With advanced technology, they ensure superior beam quality, low maintenance, and energy savings, providing cost-effective solutions for industrial operations.

Intelligent Cutting Head

Boci head offer stable performance with precise focus control, ensuring clean cuts and minimal material waste. Their advanced cooling systems improve durability, while the robust construction withstands harsh industrial conditions.

Cutting Software

The pipe cutting machine software optimizes cutting paths, reducing material waste and improving cutting efficiency. It supports various pipe sizes and shapes, ensuring high precision and accuracy. The user-friendly interface simplifies operation, while advanced algorithms enhance cutting speed and quality.

Japan Servo Motors

Japan motors offer exceptional performance with high precision, reliability, and energy efficiency. Their advanced control technology ensures smooth operation, accurate speed regulation, and fast response times.

Follow-up Support

The follow-up support device can adjust the support position in real time according to the movement of the pipe, ensuring continuous and effective support for the pipe during the cutting process. It can prevent sagging and shaking: by providing appropriate support, it prevents the pipe from sagging due to gravity or shaking during rotation, ensuring cutting accuracy.

Water Chiller

The water circulation system has high heat dissipation efficiency and can quickly reduce the temperature of the equipment, which is suitable for high-intensity and long-term welding operations. It has multiple fault alarm functions, such as high temperature, low temperature, insufficient water flow, etc., which can remind users in time to prevent equipment damage.