Tube & Sheet Laser Cutting Video On Youtube

Sheet and Tube Laser Cutting Machine Description

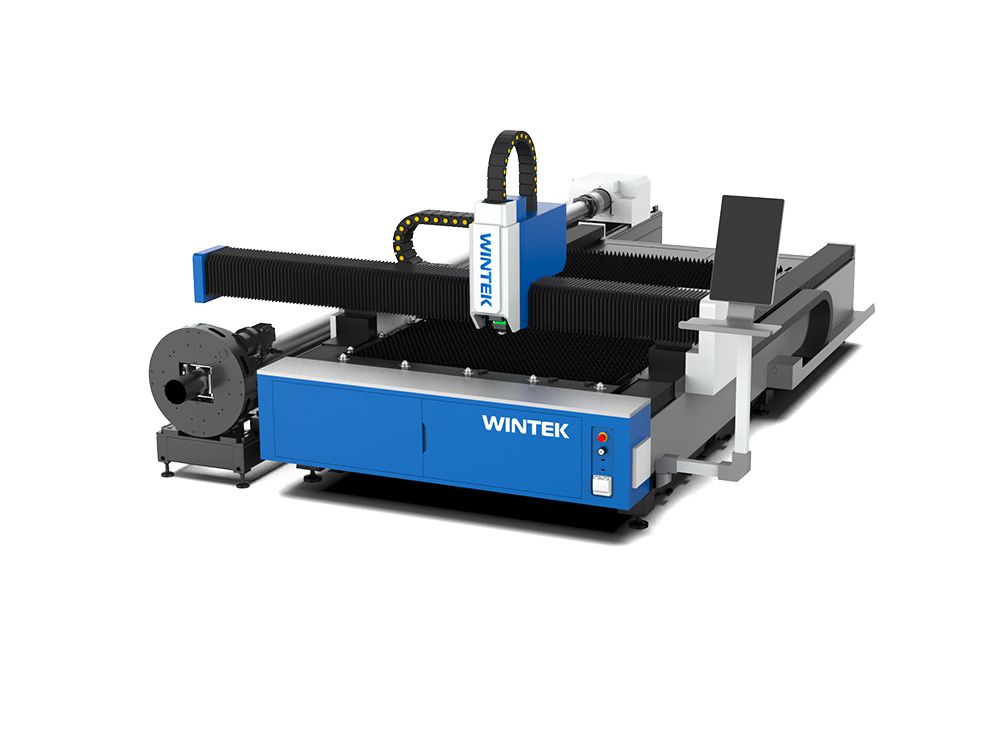

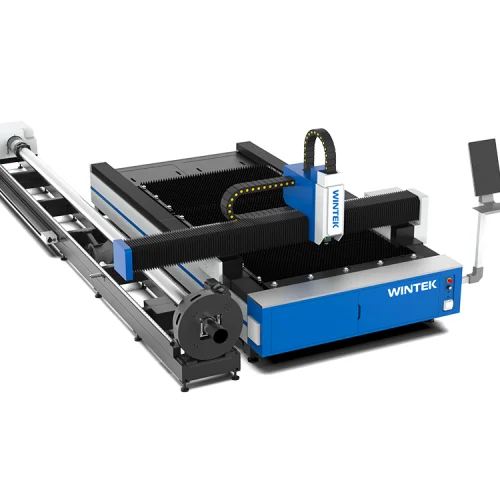

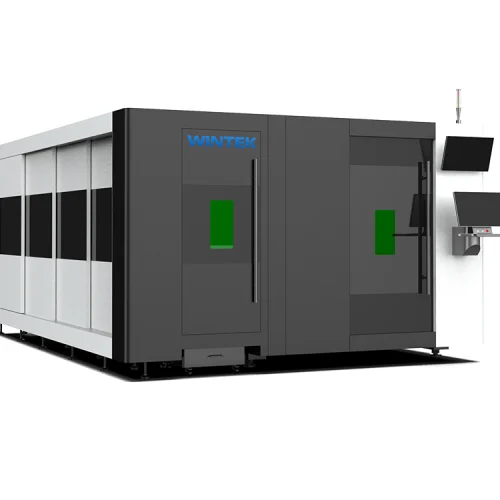

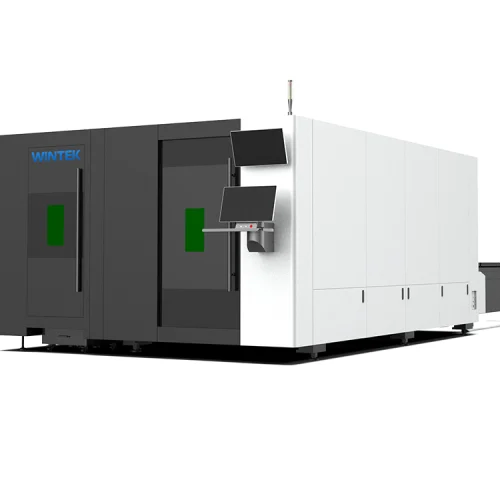

The Wintek-AT series laser cutting machine is a versatile and innovative solution that seamlessly integrates sheet metal and pipe cutting capabilities into a single system. Designed for multi-purpose applications, it excels in cutting metal sheets, as well as round, square, and special-shaped tubes, making it ideal for diverse industrial processing scenarios.

Equipped with a state-of-the-art pneumatic chuck, the machine ensures fast and secure clamping of tubes, significantly enhancing cutting stability and operational efficiency. Advanced fiber laser technology provides excellent photoelectric conversion efficiency and fast cutting speed, which can provide precise, high-quality cutting results on various materials. This cutting-edge machine is widely adopted in industries such as sheet metal fabrication, automotive manufacturing, and metal furniture production.

Technical Parameters

The fiber laser sheet and tube cutting machine combines the capabilities of both sheet and tube cutting, offering high precision, efficiency, and versatility—an ideal solution for diverse metal processing needs. Below are the detailed specifications:

| Product Name | WT-3015AT | WT-4020AT | WT-6015AT | WT-6020AT | WT-6025AT |

| Metal Sheet Cutting Length | 3000*1500mm | 4000*2000mm | 6000*1500mm | 6000*2000mm | 6000*2500mm |

| Laser Power | 1KW-6KW | ||||

| Maximum tube length | 6200mm | ||||

| Tube Size Range | 15-240mm/15-350mm | ||||

| Maximum load of chuck | 600kg | ||||

| Positioning Accuracy | ±0.03mm | ||||

| Repeat Positioning Accuracy | ±0.02mm | ||||

Sheet Tube Laser Cutter Sample

Machine Configuration

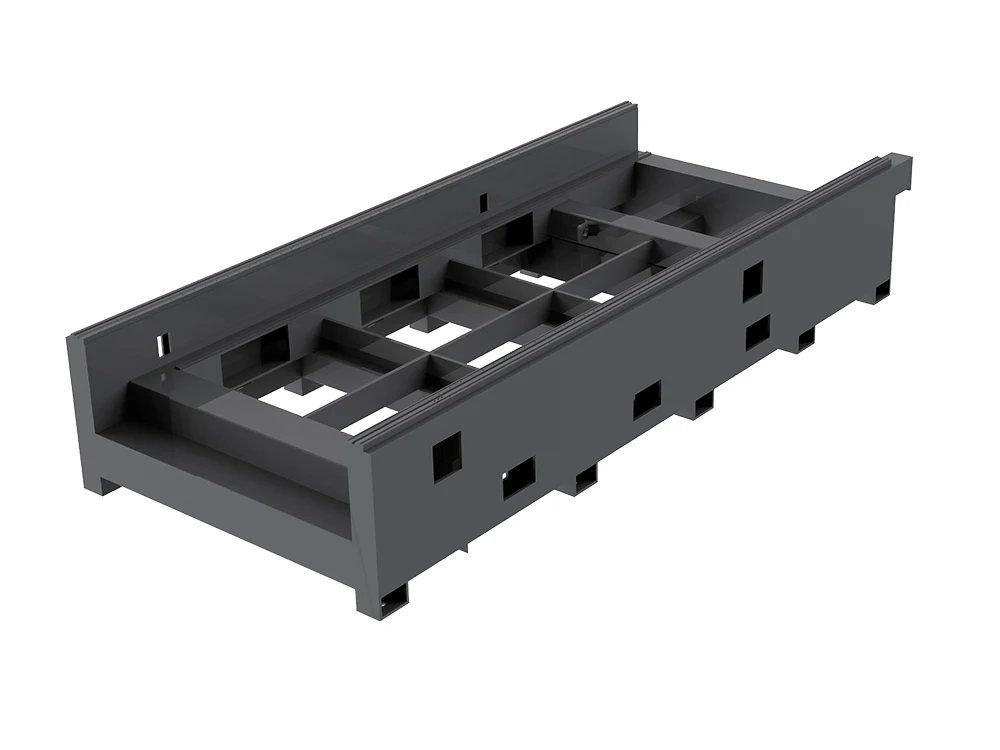

Heavy Structure

The heavy-duty bed frame of a laser cutting machine is designed for superior stability and durability, ensuring precision even during high-speed operations. Its robust construction supports heavy workloads and enhances cutting accuracy, making it ideal for processing thick materials.

Automatic Focus Cutting Head

The laser cutting head on cutting machines feature advanced optics for precise and efficient material processing. With adjustable focus and robust design, it handles complex cutting tasks with ease. The cutting head’s quick lens change system reduces downtime, while its anti-collision feature protects it from damage.

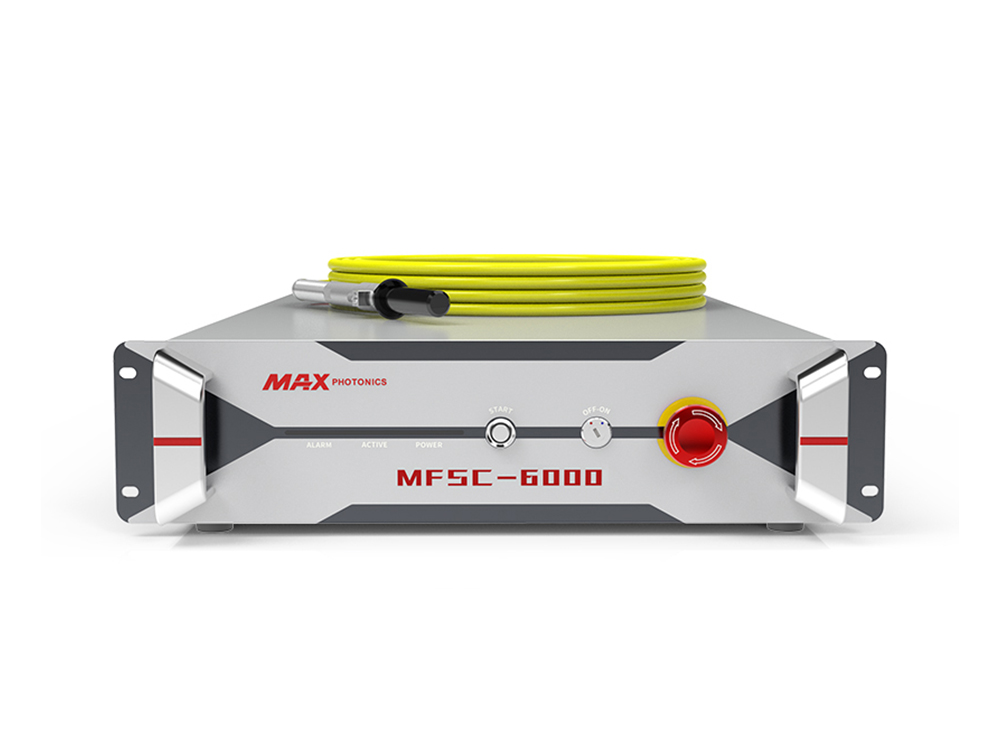

Fiber Laser Source

The laser has excellent performance and precise beam focusing, and can accurately cut various metal materials. It delivers high energy efficiency, reducing power consumption while maintaining consistent output. With a long service life and minimal maintenance requirements, it ensures reliable operation and reduced downtime.

Intelligent operation software

The CNC intelligent system is the dominant operating system of the fiber laser cutting machine. It mainly controls the machine tool to achieve the movement of the X, Y, and Z axes, and also controls the output power of the laser. Its quality determines the stability of the operating performance of the fiber laser cutting machine.

Sheet Tube Laser Cutting Machine - Other Core Components

Aviation Aluminum Beam

Taiwan Hiwin Rails & YYC Gears

Japan SHIMPO Reducer

Water Chiller

Sheet Tube Laser Cutting Machine Benefits

- Dual-Purpose Functionality

Combines the ability to cut both metal sheets and tubes in a single machine, reducing equipment costs and saving workspace.

Handles a variety of tube shapes, including round, square, and special profiles, providing unmatched versatility.

- High Precision and Efficiency

Fiber laser technology ensures accurate and consistent cuts with minimal material waste.

Fast cutting speeds improve productivity while maintaining excellent edge quality.

- Enhanced Automation

Pneumatic chucks enable quick and secure tube clamping, minimizing setup time and ensuring stability during cutting.

Automated software allows easy programming and customization of cutting paths for complex designs.

- Cost Savings

Reduces reliance on multiple machines, lowering operational and maintenance costs.

Energy-efficient fiber laser systems cut operating expenses while delivering high performance.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.