Tube & Sheet Laser Cutting Video On Youtube

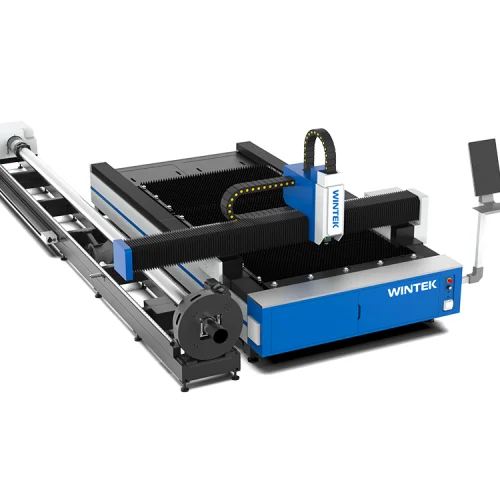

Sheet and Tube Laser Cutting Machine Description

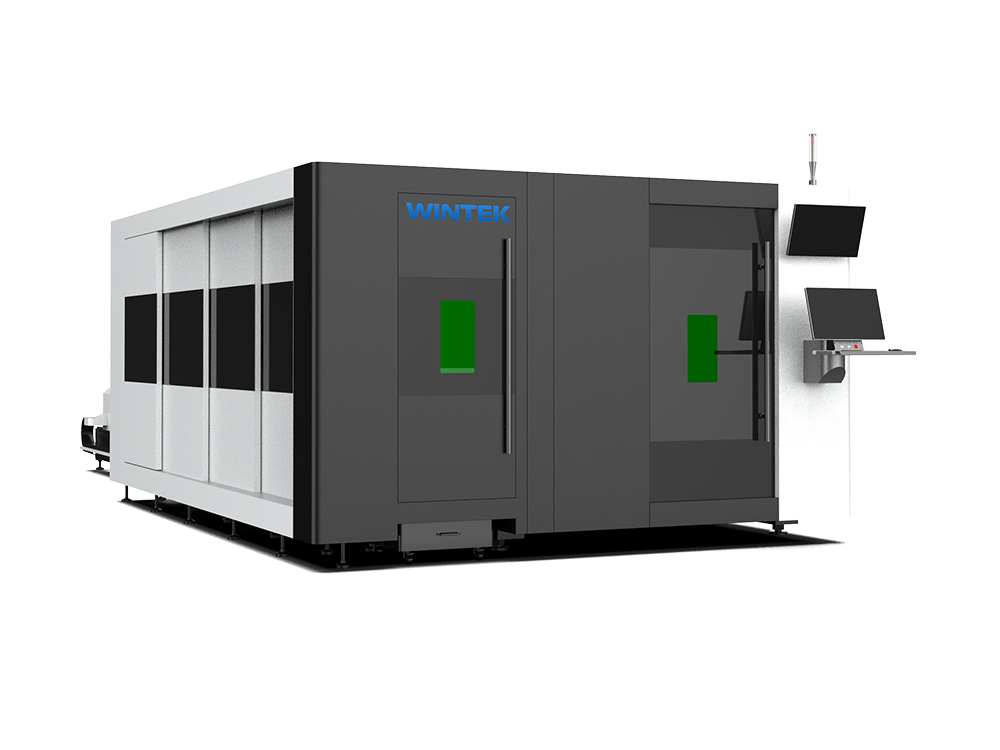

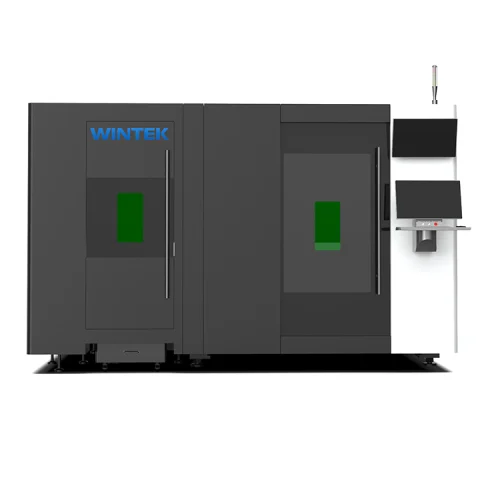

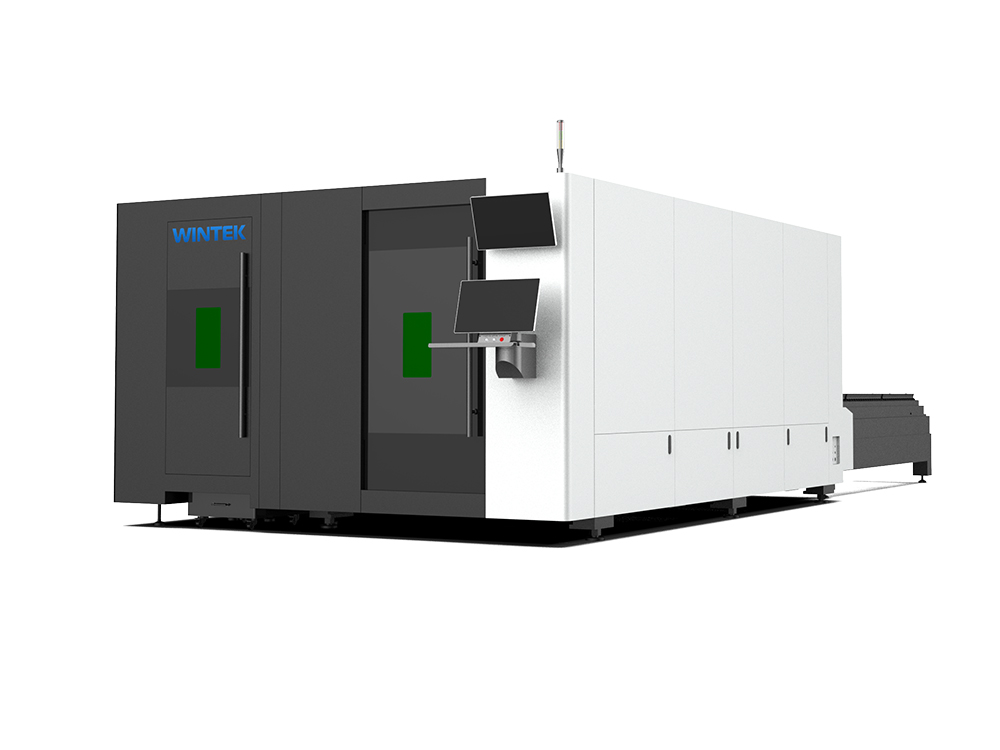

Wintek-ATP series laser cutting machine is a high-power, fully enclosed, safe and environmentally friendly laser processing equipment that integrates plate cutting and pipe cutting. It adopts a large enclosure protection design to effectively prevent laser radiation, improving safety and environmental protection performance.

Equipped with an intelligent exchange workbench, it can complete loading and unloading while cutting, improving production efficiency. It is suitable for metal materials such as carbon steel, stainless steel, aluminum alloy, copper, etc., and is widely used in sheet metal processing, machinery manufacturing, automotive parts, building structures and other industries.

The sheet tube fiber laser cutting machine meet customer needs for both flat plate cutting and cutting various shaped tubes, such as round and square tubes. The built-in partition dust removal design reduces smoke and dust pollution and ensures a clean workspace.

Technical Parameters

The fiber laser sheet and tube cutting machine combines the capabilities of both sheet and tube cutting, offering high precision, efficiency, and versatility—an ideal solution for diverse metal processing needs. Below are the detailed specifications:

| Product Name | WT3015ATP | WT4020ATP | WT6020ATP | WT6025ATP |

| Working Area | 3050*1530mm | 4050*2030mm | 6050*2030mm | 6050*2530mm |

| Acceleration | 1.5G | 1.5G | 1.5G | 1.5G |

| Maximum tube length | 6200mm | 6200mm | 6200mm | 6200mm |

| Max Running Speed | 120m/min | 120m/min | 120m/min | 120m/min |

| Positioning Accuracy | ±0.03mm/m | |||

| Repeatability Accuracy | ±0.02mm | |||

| Power | 1KW-30KW | |||

| Loading Weight of Tube | 300kg | 300kg | 300kg | 300kg |

| Loading Weight of Sheet | 1500kg | 2500kg | 2950kg | 3900kg |

| Dimensions | 9100*4100*2350mm | 11100*4650*2350mm | 15100*4100*2350mm | 15100*4650*2350mm |

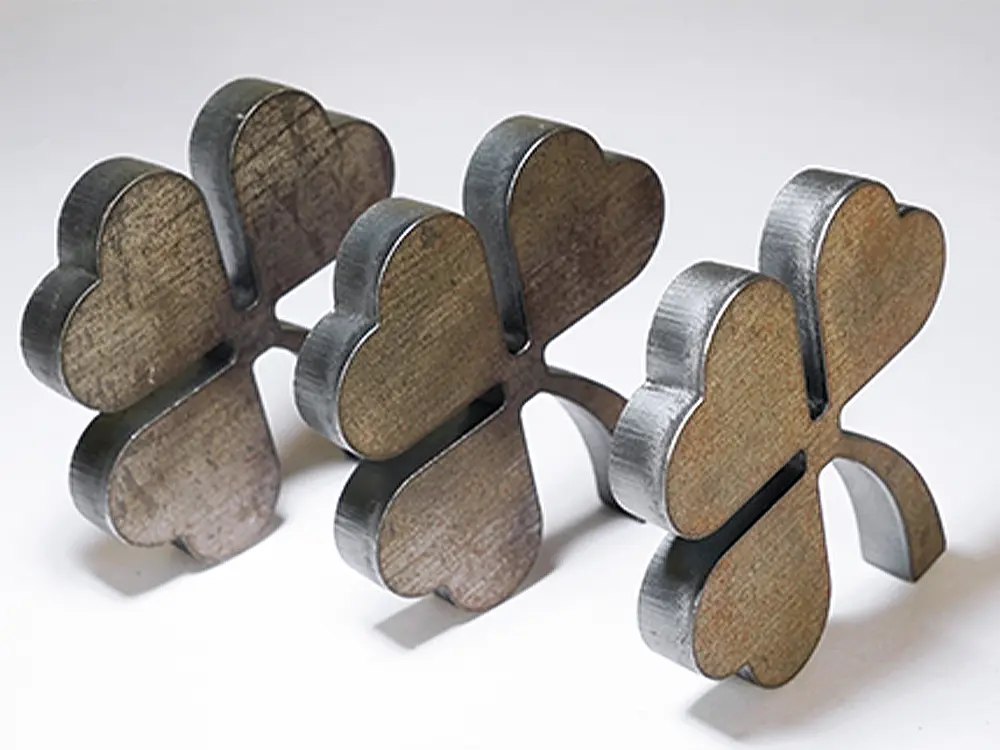

Sheet Tube Laser Cutter Sample

Machine Configuration

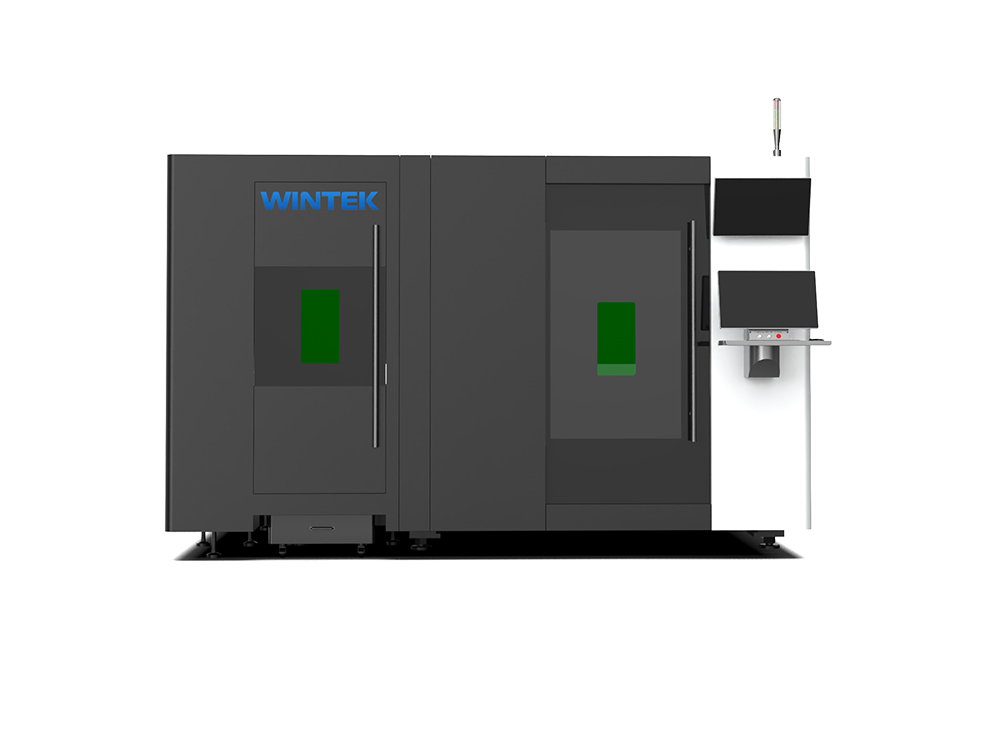

Enclosed Sheet and Tube Integrated Design

Fully enclosed sheet and tube integrated design.

Dual-functionality in a single machine for exceptional value and efficiency.

Capable of managing a broader range of cutting conditions.

Guarantees safe and reliable operation.

Plate Welding Machine Bed

The bed features a welded design with high-rigidity materials, preventing deformation during high-speed, high-power laser cutting for stable performance. Optimized structure and material selection minimize vibration, ensuring cutting accuracy and stability.

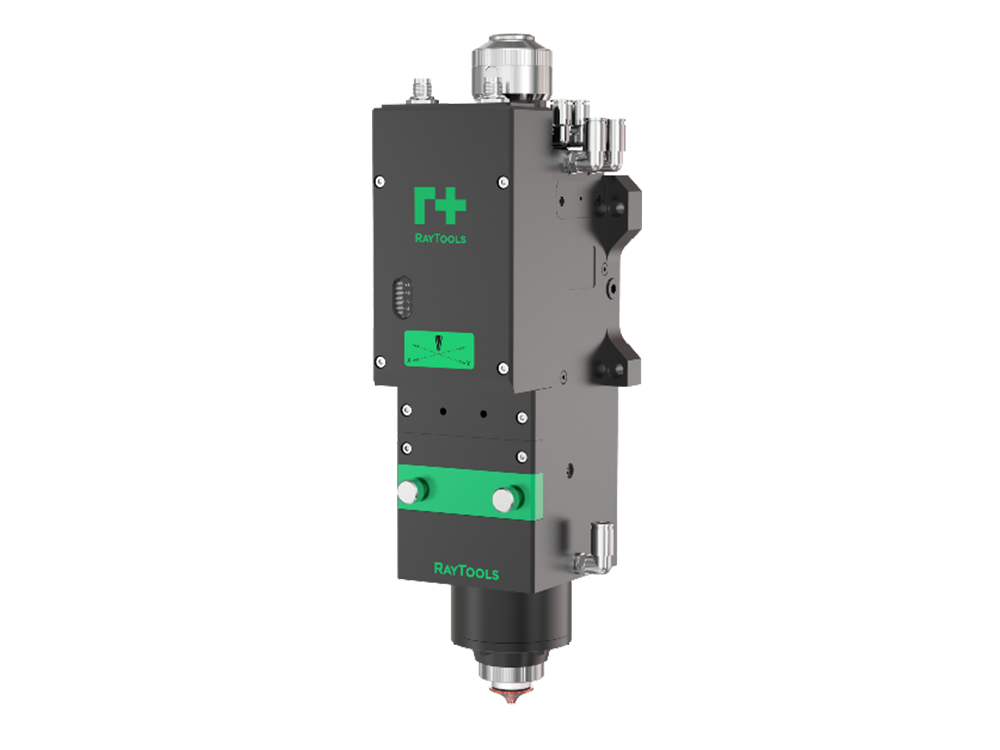

Auto Focus Laser Head

The laser head is equipped with various fiber interfaces, including QBH, QD, and G5, making it compatible with a wide range of mainstream lasers. It features a lower protective lens temperature monitoring function, with temperature data displayed in real-time through a mobile app or desktop window.

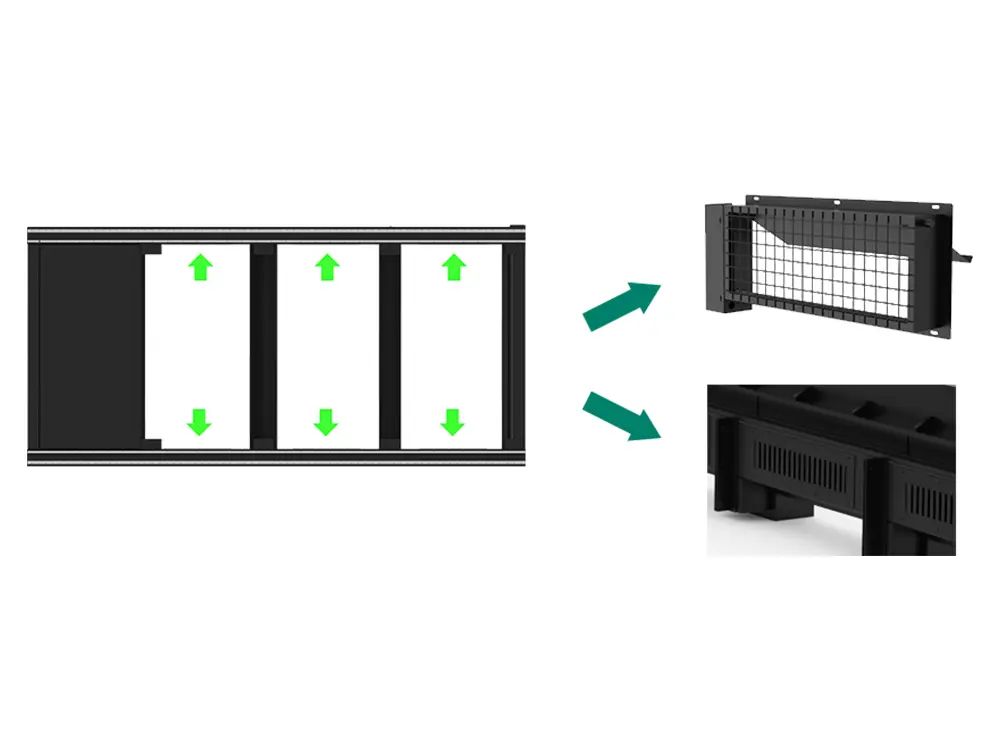

Zoned Dust Removal Design

Featuring a dual-side extraction design, the upgraded large-diameter, multi-zone optimized air duct significantly improves dust removal efficiency compared to central extraction systems.

Sheet Tube Laser Cutting Machine - Other Core Components

Fiber Laser Source

Taiwan Hiwin Rails & YYC Gears

Intelligent Operating System

Aviation Grade Tensile Aluminum Beam

Sheet Tube Laser Cutting Machine Benefits

Full-Enclosure Design for Safety and Environmental Protection

The fully enclosed structure improves operational safety by isolating laser radiation and protects operators from potential hazards. Additionally, it prevents the leakage of dust and smoke generated during cutting, creating a cleaner and healthier work environment.

High Precision Cutting with Reliable Quality

Utilizing advanced fiber laser technology and a high-precision transmission system, the machine ensures smooth, burr-free edges with minimal dimensional errors, meeting the stringent standards of high-quality processing.

Intelligent Operation for Enhanced Efficiency

The automated loading and unloading system, combined with smart clamping designs, simplifies workflows and significantly boosts production efficiency. Operators can easily set cutting parameters via a user-friendly interface, enabling quick material changes and automated processing.

Stable Performance for High-Speed Processing

The enclosed design enhances structural stability, ensuring smooth operation even during high-speed processing and preventing vibrations from affecting cutting accuracy.

Multifunctional Design for Diverse Industry Needs

The machine supports cutting round tubes, square tubes, rectangular tubes, and custom profiles, making it ideal for applications in automotive, construction machinery, furniture, aerospace, and metal fabrication industries.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.