▍Handheld Laser Cleaning Machine Description

A handheld laser cleaning machine is an advanced, compact, and portable device designed for precise and efficient surface cleaning across various industries. Utilizing a focused, high-intensity laser beam, it effectively removes rust, paint, oxides, oil, and other contaminants from metal surfaces without causing damage to the base material. The cleaning process is fast, highly efficient, and easy to control, significantly boosting productivity while minimizing operational costs.

This eco-friendly technology eliminates the need for chemicals, abrasive materials, or water, making it a sustainable and low-maintenance alternative to traditional cleaning methods. Its non-contact nature ensures safety for delicate surfaces, and adjustable laser parameters allow for customization to meet specific cleaning requirements.

Handheld laser cleaning machines are widely used in industries such as marine, automotive, aerospace, rubber mold manufacturing, high-end machine tool maintenance, tire production, rail cleaning, and environmental protection. With their portability, reliability, and precision, they are ideal for applications requiring high-quality cleaning and surface preparation, including weld cleaning, paint stripping, and oxide removal in industrial and restoration settings.

▍Handheld Laser Cleaning Machine 1000W- 3000W Parameters

| Laser Power | WTC-1000w / WTC-1500w / WTC-2000w / WTC-3000w |

| Welding System | Sup Laser |

| Welding Head | Sup22C |

| Water Chiller | Hanli or S&A ( Water Cooling ) |

| Fiber Cable Length | 10m ( Maximum is 20m) |

| Laser Wavelength | 1070nm |

| Laser Frequency | 5-5000Hz |

| Scan Frequency | 10-100Hz |

| Cleaning Width | 300mm |

| Machine Size / Packing Size | 88cm*57cm*104cm / 131cm*71cm*131cm |

| Machine Weight / Packing Weight | 185KG / 200KG |

| Consumable Parts | 10 pcs protective lens |

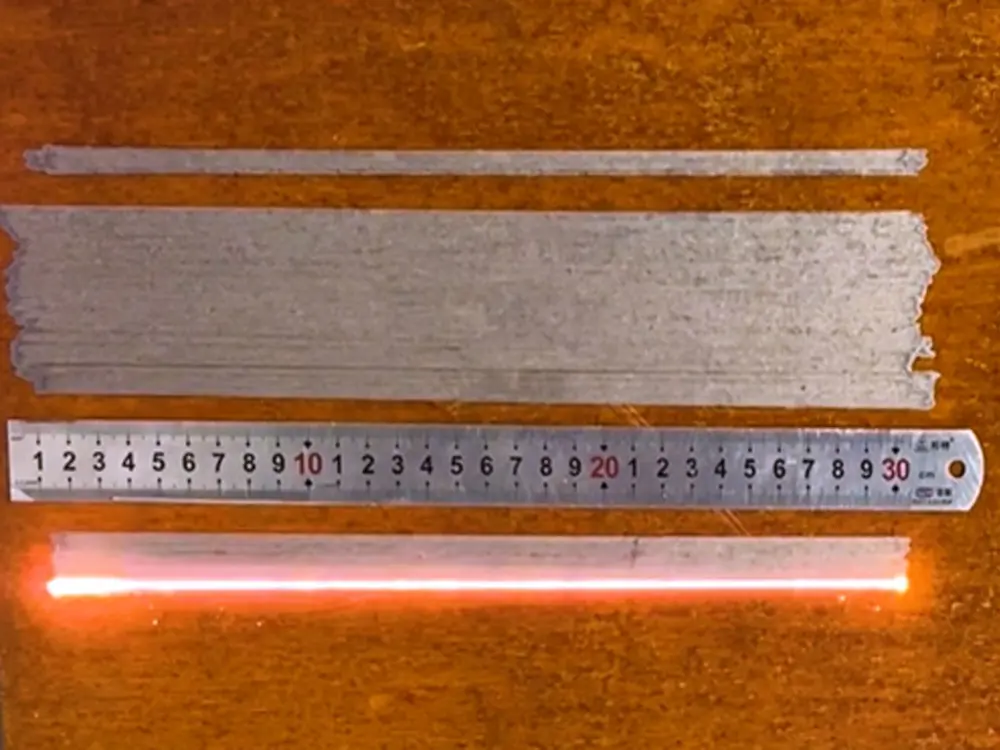

▍Handheld Laser Cleaning Machine Sample

▍Handheld Laser Cleaning Machine Configuration

Continuous Laser Source

Ideal for removing rust from metal, stripping coatings, and cleaning welds. This advanced solution requires no chemical reagents, ensuring an environmentally friendly, efficient, and substrate-safe process.

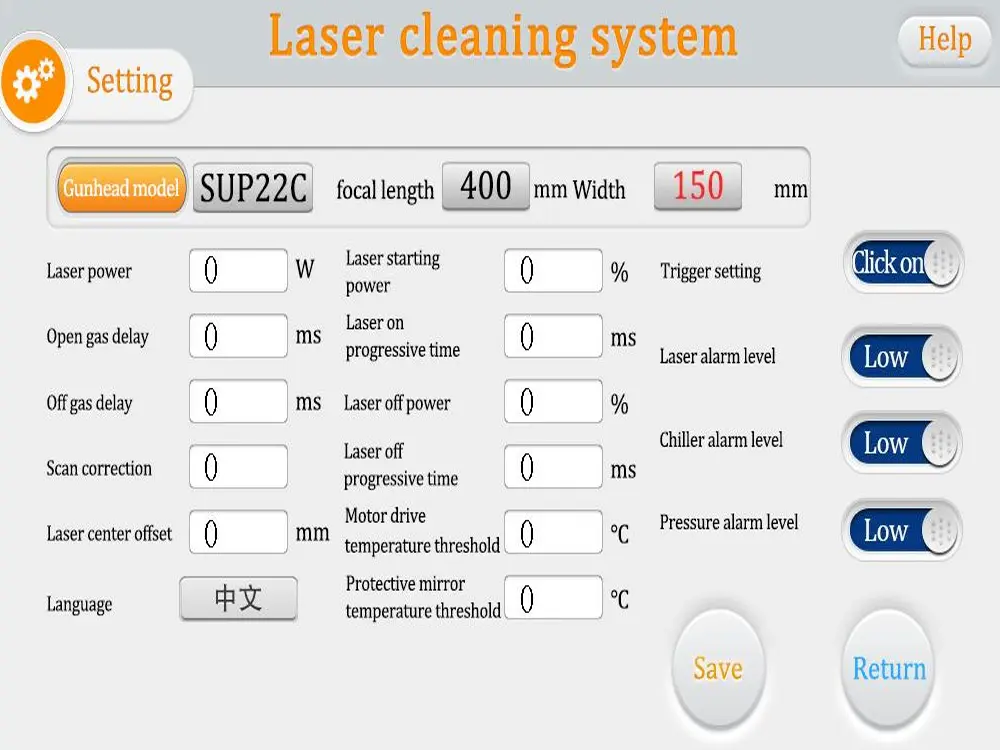

Laser Cleaning Gun

It can adapt to various cleaning needs within 3000W. The operation is simple and flexible, and all parameters are intuitively visible, and the status of the whole machine is monitored in real time. Avoid problems in advance, facilitate troubleshooting and troubleshooting, and ensure the stable operation of the handheld cleaning head.

Laser Cleaning System

Laser cleaning machine is widely used in industrial cleaning fields such as metal rust removal, coating removal, oil cleaning, weld cleaning, oxide layer removal, etc. Compared with traditional chemical cleaning, laser cleaning technology has significant advantages such as non-destructive, environmentally friendly, high efficiency and precise control.

Cleaning distance can reach 800mm

Cleaning distance can reach 800mm, providing flexibility for handling various cleaning tasks, including those on uneven or hard-to-reach surfaces. The extended range ensures safe and efficient operation without compromising precision or effectiveness.

▍Handheld Laser Cleaning Machine Benefits

1. High Cleaning Efficiency: Continuous laser provides stable beam output, significantly improving cleaning efficiency, especially for large surface areas.

2. Non-Damaging Cleaning: Non-contact process prevents surface damage, making it ideal for cleaning precision equipment and molds.

3. Environmentally Friendly: No need for chemical cleaning agents, avoiding hazardous waste generation. It aligns with modern sustainable industrial practices.

4. Versatile Applications: Effectively removes rust, grease, coatings, oxides, and various surface contaminants. Suitable for different materials like metal, plastic, and glass.

5. Portable and Flexible: Lightweight and ergonomic handheld design ensures easy operation, even in tight spaces or on complex components.

6. Precise Control: Adjustable laser power and cleaning parameters allow customization for different materials and contaminants, ensuring optimal results.

7. Reduced Maintenance Costs: Requires no consumables or easily worn-out components, resulting in low operating costs over time.

8. Smart Operation: Can integrate with automated control systems for intelligent monitoring and remote operation, enhancing efficiency and safety.

▍Handheld Laser Cleaning Machine FAQs

Q: What types of contaminants can the metal laser cleaner remove?

Our metal laser cleaning machine excels at removing rust, paint, and coatings. It is also highly effective at tackling various types of industrial grime, making it a versatile solution for a wide range of cleaning applications. Additionally, it ensures precise and damage-free cleaning, preserving the integrity of the underlying material.

Q: How long can a handheld laser cleaner operate continuously?

Our handheld laser cleaning machines are designed for durability, with the ability to operate continuously for up to 48 hours. The exact runtime depends on the machine’s design and cooling system, but with proper maintenance and cooling, most models can function seamlessly for extended periods.

Q: What are the main applications of continuous laser cleaning machines?

Continuous laser cleaning machines are primarily used for efficient rust removal, coating stripping, weld cleaning, and mold surface cleaning, effectively eliminating contaminants without damaging the substrate.

Q: What should be noted when using a hand held laser cleaning machine?

When using a handheld laser cleaning machine, ensure the operation area is well-ventilated, wear protective laser glasses to avoid direct exposure, and select appropriate laser power and scanning parameters based on the cleaning requirements.

Contact us now to explore our handheld laser cleaning machines. Fill out the form for a personalized quote.