▍Pulse Laser Cleaning Machine Description

The pulse cleaning machine uses high-intensity laser pulses to remove contaminants, rust, coatings, and oxides from a wide range of materials. This cutting-edge method ensures precise and efficient cleaning without causing damage to the underlying substrate, making it especially suitable for metals such as steel, aluminum, and copper. It is widely utilized in industries like automotive, aerospace, and manufacturing, particularly for surface preparation, maintenance, and restoration tasks.

Equipped with compact, portable housing and built-in wheels for mobility, this machine is designed for convenient use in various industrial environments. Its intuitive touchscreen interface allows for seamless control, while the ergonomic handle ensures easy maneuverability.

In addition to its exceptional performance, the machine stands out for its eco-friendly operation. It eliminates the need for chemicals, significantly reducing environmental impact and minimizing waste production. The cleaning process is highly precise, allowing for targeted applications while preserving delicate surfaces, making it a versatile tool for industrial use.

▍200W 300W Pulse Laser Cleaning Machine Parameters

| Pulse Laser Cleaning Machine Parameters | ||

|---|---|---|

| Model | WTC-200W | WTC-300W |

| Pulse Frequency Range | 1-4000khz | |

| Maximum Pulse Energy | 1.5mJ / 5mJ (WTC-200W), 1.5mJ / 5mJ / 15mJ (WTC-300W) | |

| Pulse Width | 2-500ns | |

| Fiber Cable Length | 5 meters | |

| Central Wavelength | 1064nm | |

| Cleaning Range | 105×105mm, 140×140mm, 160×160mm, 185×185mm, 300×300mm (Optional) | |

| Power Consumption | 800W | 1200W |

| Power Supply Voltage | 48V | |

| Cooling Method | Air-cooled | |

| Anti-reflective Protection | Yes | |

| Power Requirements | 110V/220V 50/60Hz | |

▍Pulse Laser Cleaning Machine Sample

▍Pulse Laser Cleaning Machine Configuration

Pulse Laser Source

The pulse laser cleaning machine uses high-power fiber lasers that emit short, intense pulses of light to remove contaminants. These lasers are known for their precision, efficiency, and ability to clean without damaging surfaces. They make the cleaning process faster and more effective.

Pulse Laser Cleaning Machine

The water chiller used in pulse cleaning machines ensures optimal cooling of the laser system during operation. It maintains a stable temperature, preventing overheating and ensuring consistent performance.

Laser Cleaning Head

Pulse cleaning machine head is designed to focus and direct high-intensity laser pulses onto the surface for efficient cleaning. It features precise optics to ensure accurate targeting and uniform cleaning. Lightweight and ergonomic, it provides ease of use, especially for handheld applications.

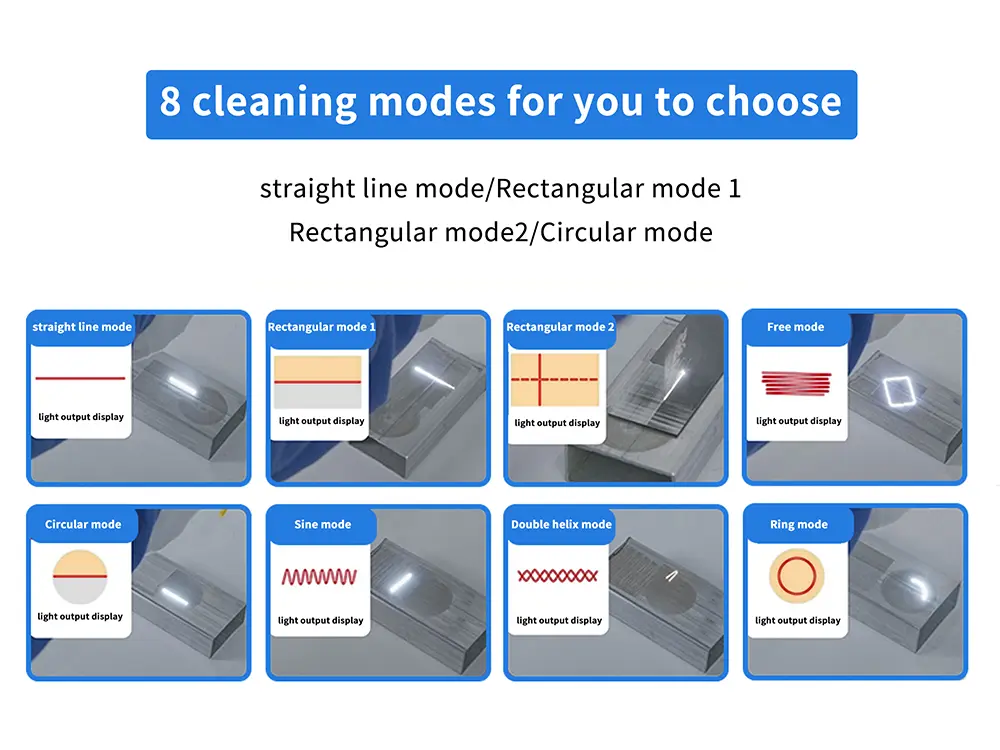

8 Cleaning Modes of Pulse Laser Cleaning Machine

The pulse laser cleaning machine supports eight unique cleaning modes: straight line, rectangular (mode 1 and mode 2), circular, sine wave, double helix, free-form, and ring. These modes ensure adaptability for various applications, such as rust removal, surface preparation, and restoration, making the machine suitable for cleaning complex shapes, uneven surfaces, and areas requiring high precision.

▍Pulse Laser Cleaning Machine Benefits

- Efficient Cleaning: Quickly removes dirt, oxides, and coatings with high efficiency.

- Non-damaging: Causes minimal to no damage to the substrate, preserving the integrity of the workpiece.

- Non-contact Method: No direct contact with the workpiece, avoiding mechanical wear or surface damage.

- High Precision: Precisely targets cleaning areas, suitable for complex shapes and small components.

- Fast and Productive: Delivers high-speed cleaning, ideal for large-scale industrial applications.

- Low Energy Consumption: Concentrated laser energy reduces power usage, ensuring cost-effectiveness.

- Low Maintenance Costs: Simple to maintain with long laser lifespan, minimizing operational costs.

- Wide Applicability: Effective for metals, non-metals, industrial equipment, and even artifact restoration across various fields.

▍Pulse Laser Cleaning Machine FAQs

Q: What is the principle of pulse laser cleaning?

Pulse laser cleaning works by directing high-energy laser pulses at the surface of a workpiece, causing contaminants, rust, coatings, or oxides to rapidly vaporize or peel away without harming the underlying material. This non-contact, chemical-free process ensures precise and efficient cleaning with minimal heat transfer, making it safe for delicate surfaces and environmentally friendly.

Q: Does the pulse laser cleaning machine support cleaning precision components?

Yes, the high precision of laser cleaning technology makes it ideal for cleaning delicate components such as aerospace parts and electronic devices. Its controlled energy application ensures thorough cleaning without causing damage, maintaining the integrity of sensitive materials and intricate geometries.

Q: What materials are suitable for pulse laser cleaning machines?

Pulse laser cleaning machines are highly versatile and compatible with a wide range of materials, including metals such as steel, aluminum, copper, titanium, and alloys. They are also effective on certain non-metallic materials like ceramics, plastics, wood, and composites, depending on the specific application.

Q: Can pulse laser cleaning machines be used for outdoor operations?

Yes, many models are designed to be portable and suitable for outdoor use, making them ideal for on-site cleaning tasks in industries such as construction, shipbuilding, and maintenance. These machines often come equipped with rugged designs to withstand outdoor conditions, including variable temperatures and humidity. However, for optimal performance and safety, it is recommended to operate in a well-ventilated area.

Contact us now to explore our pulse laser cleaning machines. Fill out the form for a personalized quote.