▍3 in 1 Laser Welding Cleaning Cutting Machine Description

The 3 in 1 laser welding machine is a multifunctional device that integrates the three key functions of welding, cutting and cleaning. It is designed to simplify industrial processes by providing comprehensive solutions for various applications.

WINTEK adopts a precision sheet metal cabinet structure, which runs smoothly and has high stability. The equipment is equipped with imported optical lenses and precision welding gun heads, which have uniform light output and full light spots, and the welding products can achieve high-precision full welding effects.

It is easy to operate, and no professional welder is required. With simple training, you can quickly get started.

▍3 in 1 Laser Welding Machine 1KW-3KW Parameters

| MODEL | WTW-1500 | WTW-2000 | WTW-3000 |

|---|---|---|---|

| Laser Welding Thickness | Carbon steel: 4mm Stainless steel: 4mm Aluminum: 2mm |

Carbon steel: 5mm Stainless steel: 5mm Aluminum: 3mm |

Carbon steel: 8mm Stainless steel: 8mm Aluminum: 5mm |

| Laser Power | 1500W | 2000W | 3000W |

| Operational Voltage | Single Phase 220V 50/60HZ | Single Phase 220V 50/60HZ | Three Phase 380V 50/60HZ |

| Laser Wavelength | 1080nm | 1080nm | 1080nm |

| Fiber Cable Length | 10-20m | 10-20m | 10-20m |

| Maximum Welding Speed | 0.5-120mm/s | 0.5-120mm/s | 0.5-120mm/s |

| Operating System | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Laser Welding Head | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Cooling System | Water cooling | Water cooling | Water cooling |

| Working Environment Temperature Range | 10-40℃ | 10-40℃ | 10-40℃ |

| Automatic Wire Feeder | √ | √ | √ |

| Laser Welding Machine Dimensions | 1230*650*1080mm | 1230*650*1080mm | 1230*650*1080mm |

| Laser Welder Machine Weight | 200KG | 200KG | 200KG |

| Laser Welding Gun Weight | 0.75kg | 0.75kg | 0.75kg |

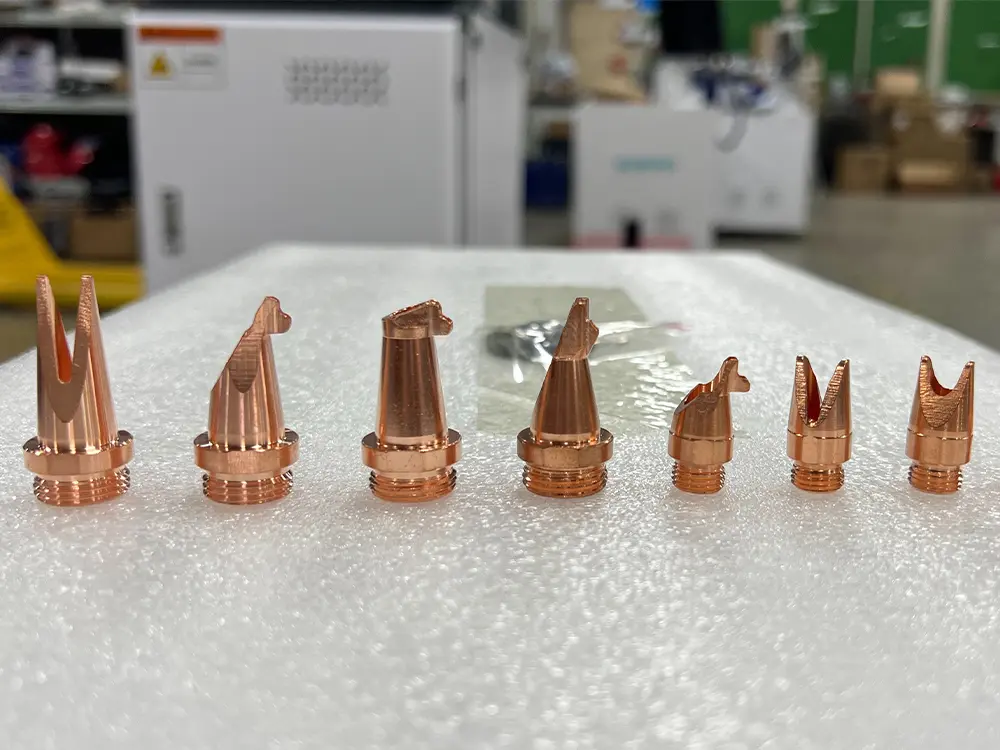

| Consumable Parts | 10 pcs nozzles, 10 pcs protective lenses | ||

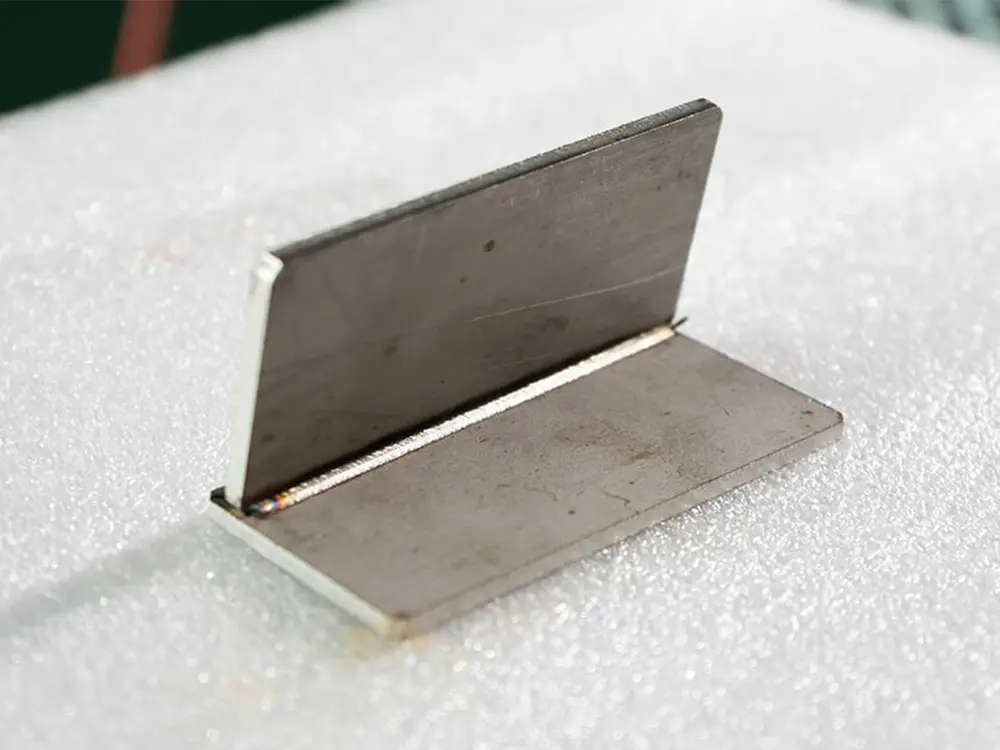

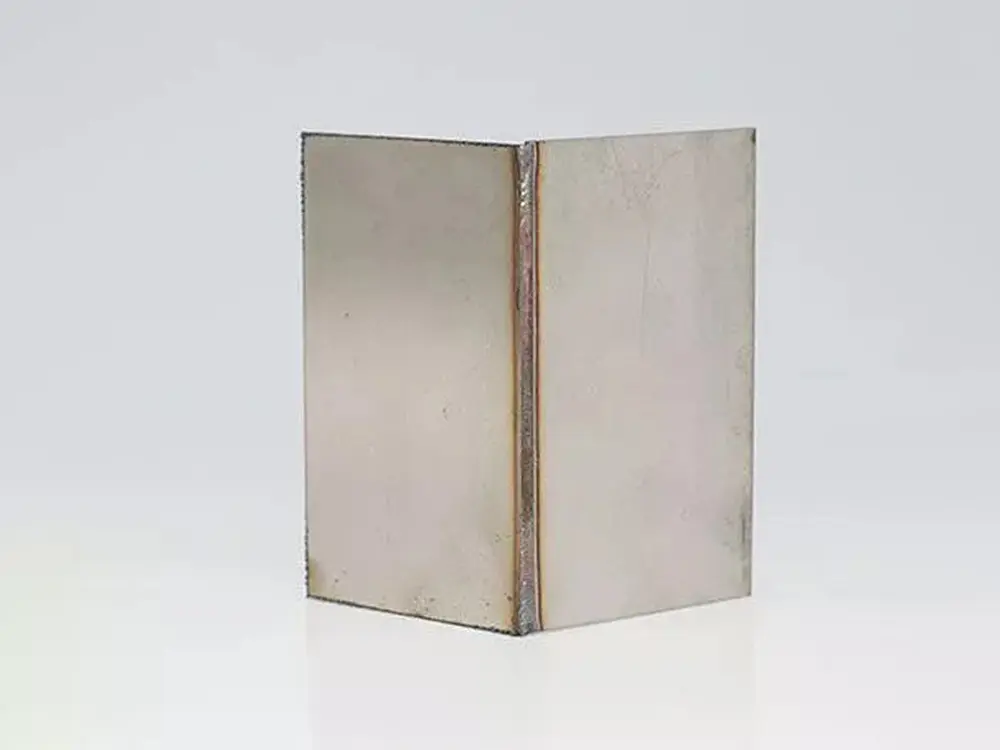

▍Handheld Metal Laser Welding Machine Sample

▍Metal Laser Welding Machine Configuration

Laser Source

Utilizes advanced fiber lasers known for high energy efficiency, minimal maintenance, and long lifespan. Delivers stable and efficient energy for deep penetration welding, precise cutting, and effective cleaning. Compatible with various metal materials, including stainless steel, carbon steel, and aluminum, suitable for industrial applications.

3 in 1 Laser Welding Gun

Laser welding has excellent weld quality with smooth, uniform seams that require no secondary processing, meeting strict aesthetic and performance standards.

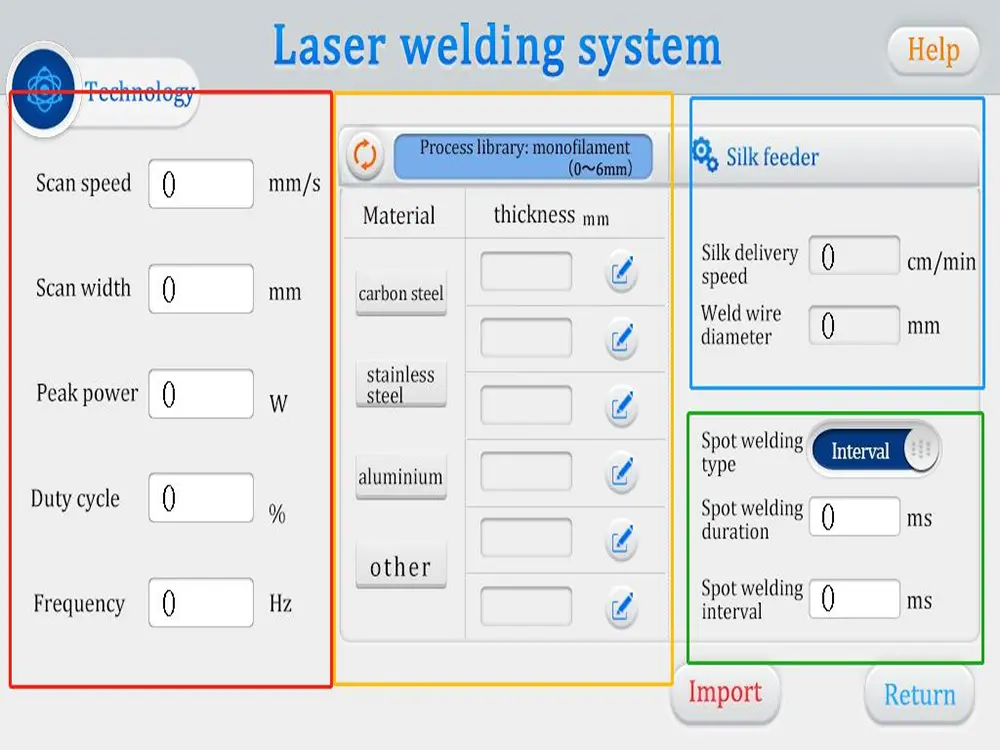

Laser Welding System

Provides an intuitive user interface that is easy to learn and operate. Can handle welding needs of irregular shapes and complex structures.

Automatic Wire Feeder

Laser welding machine wire feeder is a feeding device that assists laser welding. It is mainly used to accurately control the feeding of welding wire to improve welding quality and weld strength.

Portable Laser Welding Machine - Other Core Components

Multi Nozzles

Ground Clamp

Water Chiller

Safety Goggles

▍3 in 1 Handheld Laser Welding Machine Benefits

-

High-Efficiency Fiber Laser (1000-3000W): Equipped with a fiber laser offering high electro-optical conversion efficiency and extended service life.

-

Low Maintenance: Requires no adjustment, has low energy consumption, and uses no consumables, significantly reducing long-term processing costs.

-

Compact Design: Small and compact with an integrated water-cooling system; the handheld design enables flexible and convenient welding, including outdoor operations.

-

Handheld Welding Head: Features a 10-meter imported fiber cable, allowing for welding at any angle on complex seams, large workpieces, and irregular shapes.

-

Superior Beam Quality: Fiber transmission ensures better beam quality, providing uniform welding spots and improved penetration depth.

-

Ideal for Ultra-Thin Welding: Delivers excellent welding results, especially on ultra-thin materials where traditional TIG welding is ineffective.

▍3 in 1 Laser Welding and Cutting Machine FAQs

Q: How long is the lifespan of handheld laser welding machines?

The lifespan of hand held laser welding machine largely depends on its core components and maintenance. The laser source, being the most critical part, typically has a lifespan of over 100,000 hours under proper usage conditions.

Q: What safety precautions should be taken while using the machine?

When using a handheld laser welding machine, it is essential to prioritize safety by wearing appropriate personal protective equipment, such as laser safety glasses to protect against harmful laser radiation. Ensure the working area is well-ventilated to avoid the accumulation of fumes or gases generated during the welding process. Regularly inspect the machine for proper functionality and ensure all safety features are active, such as interlocks and emergency stop mechanisms, to prevent accidents.

Q: What training is required to operate the machine?

Operating a handheld laser welder requires basic training to ensure safe and efficient use. Training typically lasts 1-3 days and includes familiarization with the machine’s components, setup, and operating procedures. Operators will learn how to adjust parameters such as laser power, speed, and shielding gas flow for different materials and thicknesses. Training emphasizes safety procedures, including the use of protective equipment and the operation of high-energy lasers.

Q: What are the applications of handheld laser welder machines?

Handheld laser welding machines are versatile tools used in various industries due to their precision, portability, and efficiency. Here are some common applications:

1. Metal Fabrication:

Sheet Metal Welding: Ideal for joining thin metal sheets with minimal distortion.

Custom Metal Parts: Used to weld custom metal components, such as brackets, frames, and enclosures.

2. Automotive Industry:

Body Repairs: Excellent for repairing car body panels and structures.

Component Welding: Used in the manufacturing of exhaust systems, fuel tanks, and intricate metal parts.

3. Construction and Structural Applications: Efficient for on-site welding of stainless steel and aluminum railings, frames, and supports.

4. Electronics:

Small Components: Perfect for welding small, delicate components such as connectors, batteries, and sensors.

Circuit Boards: Utilized for precision joining on printed circuit boards (PCBs).

5. Kitchenware and Household Items: Stainless Steel Products: Commonly used for joining stainless steel kitchen sinks, utensils, and appliances.

Contact us now to explore our 3 in 1 handheld laser welders. Fill out the form for a personalized quote.