▍4 in 1 Laser Welding Machine Description

The 4 in 1 laser welding machine combines four basic functions: laser welding, laser cleaning, laser cutting and weld bead laser cleaning. The four-in-one laser welding is compact and easy to operate, supporting a variety of materials, including stainless steel, aluminum, brass, carbon steel and other metals.

The welding function delivers high-precision and strong welds, ensuring excellent quality and minimal distortion. The cutting capability allows for clean, smooth edges with remarkable accuracy, suitable for intricate designs. Meanwhile, the cleaning mode effectively removes rust, oxides, and other contaminants, preparing surfaces without damaging the base material.

This versatile machine is designed to handle diverse industrial applications, providing a comprehensive solution for efficient and precise material processing.

Laser Welding

Laser Cleaning

Laser Cutting

▍4 in 1 Handheld Laser Welder 1KW-3KW Parameters

| MODEL | WTW-1500 | WTW-2000 | WTW-3000 |

|---|---|---|---|

| Laser Welding Thickness | Carbon steel: 4mm Stainless steel: 4mm Aluminum: 2mm |

Carbon steel: 5mm Stainless steel: 5mm Aluminum: 3mm |

Carbon steel: 8mm Stainless steel: 8mm Aluminum: 5mm |

| Laser Power | 1500W | 2000W | 3000W |

| Operational Voltage | Single Phase 220V 50/60HZ | Single Phase 220V 50/60HZ | Three Phase 380V 50/60HZ |

| Laser Wavelength | 1080nm | 1080nm | 1080nm |

| Fiber Cable Length | 10-20m | 10-20m | 10-20m |

| Maximum Welding Speed | 0.5-120mm/s | 0.5-120mm/s | 0.5-120mm/s |

| Operating System | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Laser Welding Head | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Cooling System | Water cooling | Water cooling | Water cooling |

| Working Environment Temperature Range | 10-40℃ | 10-40℃ | 10-40℃ |

| Automatic Wire Feeder | √ | √ | √ |

| Laser Welding Machine Dimensions | 1230*650*1080mm | 1230*650*1080mm | 1230*650*1080mm |

| Laser Welder Machine Weight | 200KG | 200KG | 200KG |

| Laser Welding Gun Weight | 0.75kg | 0.75kg | 0.75kg |

| Consumable Parts | 10 pcs nozzles, 10 pcs protective lenses | ||

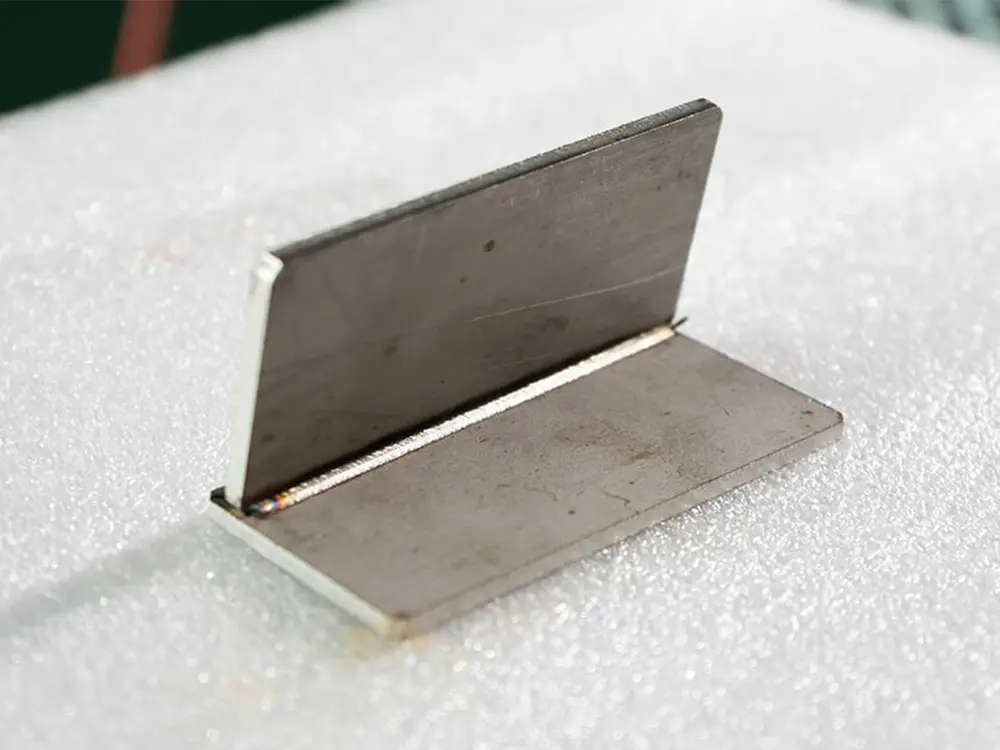

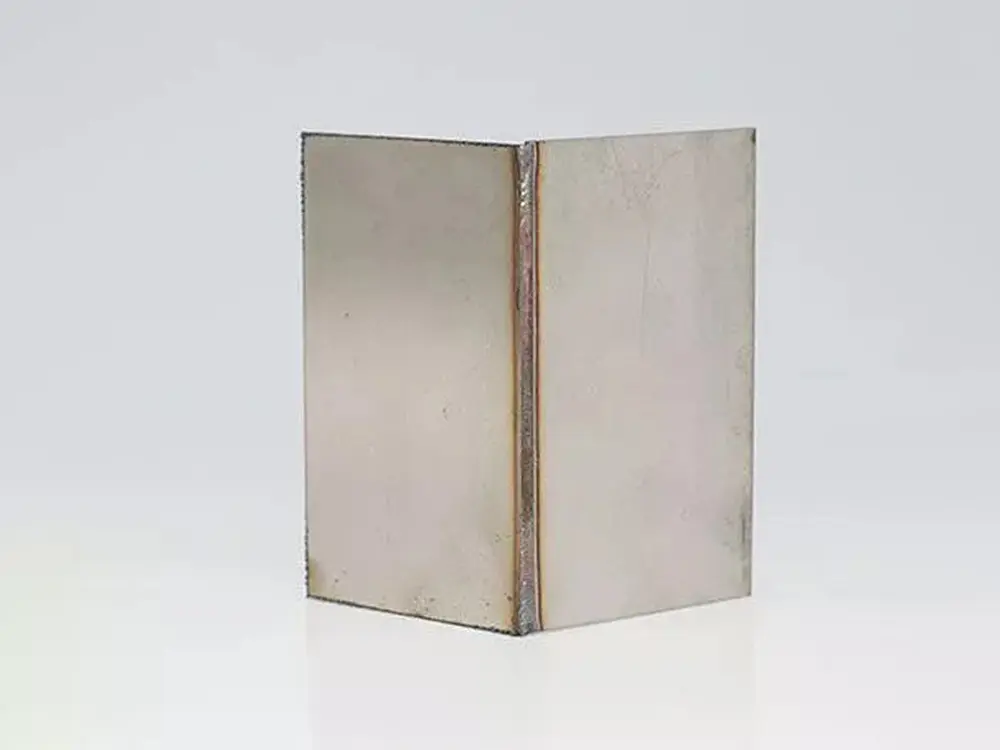

▍Handheld Metal Laser Welding Machine Sample

▍Metal Laser Welding Machine Configuration

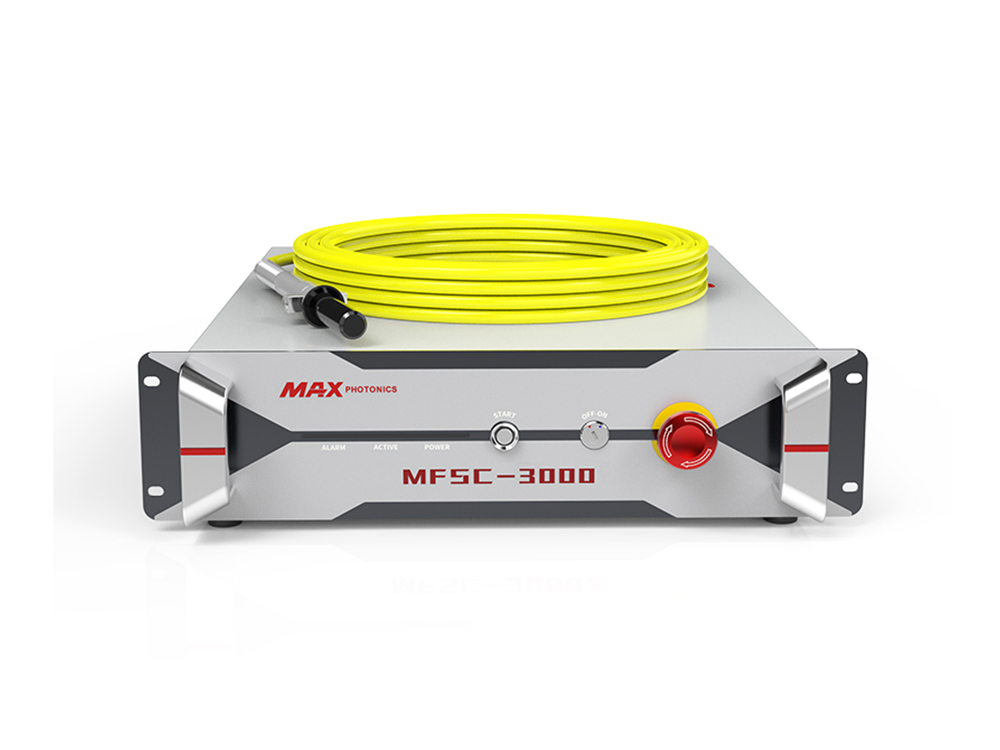

Laser Source

MAX lasers offer high efficiency and exceptional performance, providing stable, reliable operation with minimal maintenance. Known for their excellent beam quality and energy-saving design, they deliver precise, high-speed processing for applications like cutting, welding, and cleaning.

4 in 1 Laser Gun

The laser gun adapts to various welding requirements within 3000W, set multiple safety alarms and state indicator lights, abnormal state instantaneous response. The net weight of 0.75kg is flexible and easy to use.

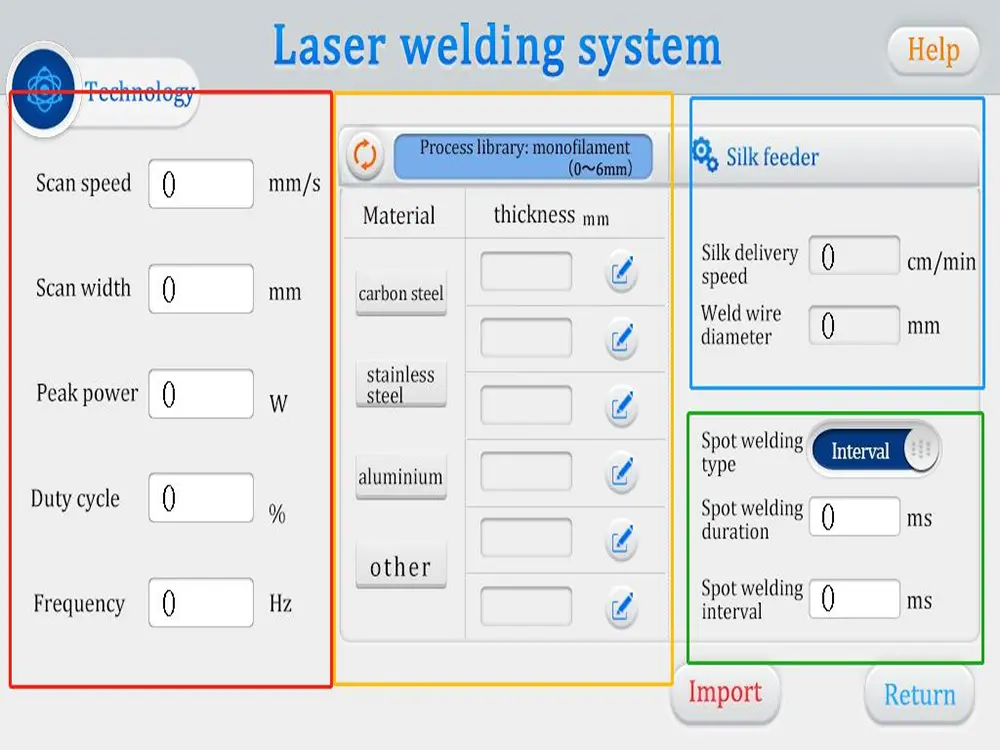

Control System

The simple and friendly interface makes the operation more user-friendly. Users can quickly and easily set various parameters and providing a better human-computer interaction experience.

Automatic Wire Feeder

The wire feeder has a smooth wire feeding process and moderate clamping force on the welding wire, which can ensure smooth wire feeding without damaging the welding wire.

Portable Laser Welding Machine - Other Core Components

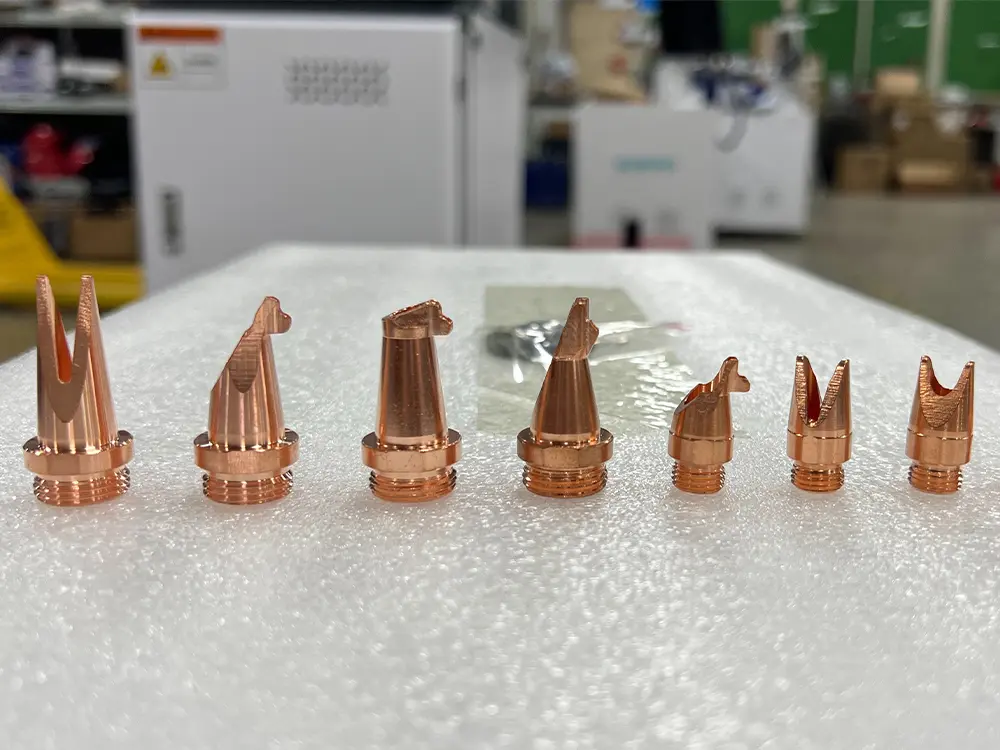

Multi Nozzles

Machine Appearance

Water Chiller

Safety Goggles

▍4 In 1 Handheld Laser Welding Machine Benefits

1. Integrated design, compact and space-saving, ideal for mobile operations. The ergonomic handheld design ensures a comfortable grip and effortless one-handed operation.

2. The high-quality water cooling system is durable and supports intensive operations, ensuring reliable performance even under harsh conditions.

3. Rich optional accessories for versatile applications: Comes standard with a wire feeder, safety goggles and essential tools. Ready to use right out of the box for easy operation.

4. The touchscreen interface is intuitive and user-friendly, supporting multiple languages. Monitor system status in real time, troubleshoot efficiently, and ensure stable operation.

5. The high-quality laser source offers an impressive optical-to-electrical conversion efficiency of over 35%. Maintenance-free operation ensures superior productivity.

6. 4-in-1 welding head meets precise requirements with an ergonomic, fully enclosed design. It ensures compatibility with various welding processes while providing lasting comfort.

▍4 in 1 Laser Welding Cutting Cleaning Machine FAQs

Q: Is the 4-in-1 handheld laser welding machine easy to move?

The 4-in-1 handheld fiber laser welder is built with mobility in mind. Its compact, lightweight design is often complemented by a wheeled base or portable frame, ensuring effortless transportation and seamless adaptability across various work environments.

Q: How fast is laser welding?

The speed of laser welding depends on factors such as power, material type, and thickness. Typically, welding speeds range from 0.5 to 120 mm/s, making it 2 to 10 times faster than traditional welding methods. This efficiency makes laser welding a highly effective solution for industrial applications.

Q: What after-sales service do we provide? How to solve problems after purchasing the machine?

We provide comprehensive after-sales service, including warranty, technical support, training, parts supply and professional maintenance. In case of any issues, customers can contact the service team for remote diagnostics, troubleshooting, or on-site repair to ensure quick and effective resolution.

Q: What are the consumables used in laser welding?

The main consumables include protective lenses and welding nozzles, which require regular replacement to ensure performance. Protective lenses safeguard the laser optics from spatter, while welding nozzles guide the laser and gas to the weld area. Additional consumables include shielding gas, such as argon or nitrogen, and cooling fluid for maintaining system temperature. Regular maintenance of these items ensures consistent welding quality.

Contact us now to explore our 4 in 1 handheld laser welders. Fill out the form for a personalized quote.