▍Air Cooled Laser Welding Machine Description

The air cooled laser welding machine is a modern and efficient solution designed for precision and portability. Weighing just 41 kg, it features a compact design with an advanced air-cooling system to ensure reliable performance. Equipped with a top handle and wheels at the base, it can be easily transported and carried by a single person, making it convenient for switching work scenarios. With a footprint of less than 0.11 m³, it offers easy integration into various production environments. Its size is comparable to a standard arc welding machine, yet it occupies less space, making it highly adaptable to different work conditions.

Compared to traditional water-cooled welding machines, the air-cooled model uses pure air cooling, eliminating the need for additional water cooling equipment, refrigerants, or compressors. This significantly reduces equipment costs, avoids the complexity of pipelines and maintenance, enhances portability, and improves the overall system’s reliability. The air-cooled system also reduces energy consumption, enabling customers to lower costs and improve operational efficiency.

Driven by an optimized fiber laser beam, the machine delivers high welding speeds and superior seam quality with seamless precision. The technology requires no consumables, ensuring excellent performance while handling a wide range of welding tasks with accuracy. This makes the air-cooled handheld laser welding machine ideal for high-demand applications. Its versatility is well-suited for industries such as automotive, electronics, and general manufacturing. It excels in welding thin-walled materials, intricate structures, and various metals, ensuring consistent results and enhancing productivity in diverse applications.

▍Air Cooled Laser Welding Machine 1200W 1500W Parameters

| MODEL | WTW-1500 |

|---|---|

| Laser Welding Thickness | Carbon steel: 4mm Stainless steel: 4mm Aluminum: 2mm |

| Laser Power | 1500W |

| Operational Voltage | Single Phase 220V 50/60HZ |

| Laser Wavelength | 1080nm |

| Fiber Cable Length | 10-20m |

| Maximum Welding Speed | 0.5-120mm/s |

| Operating System | Sup Laser / Raytools / Relfar |

| Laser Welding Head | Sup Laser / Raytools / Relfar |

| Cooling System | Air cooling |

| Working Environment Temperature Range | 10-40℃ |

| Automatic Wire Feeder Dimensions | 570*250*400mm |

| Laser Welding Machine Dimensions | 530*270*600mm |

| Laser Welder Machine Weight | 41KG |

| Laser Welding Gun Weight | 0.75kg |

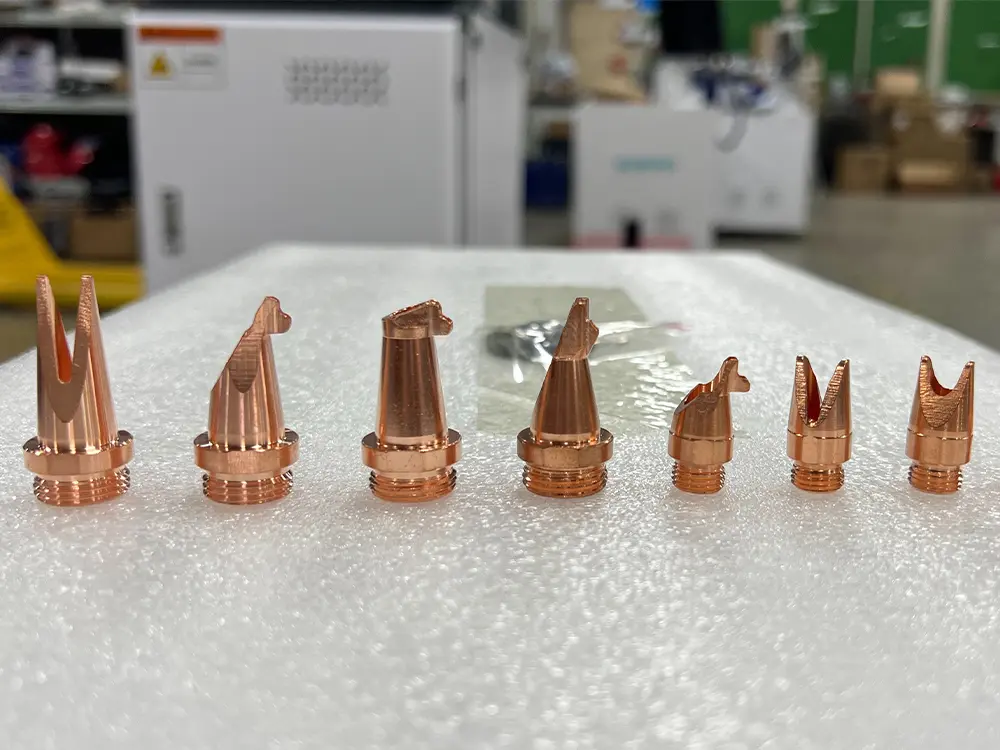

| Consumable Parts | 10 pcs nozzles, 10 pcs protective lenses |

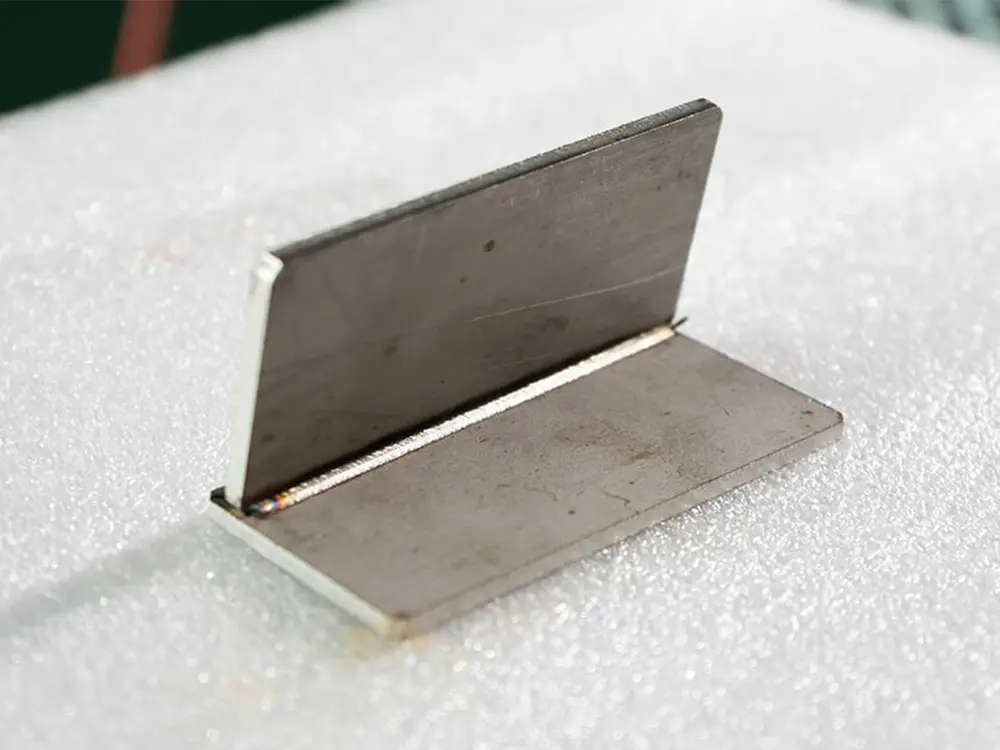

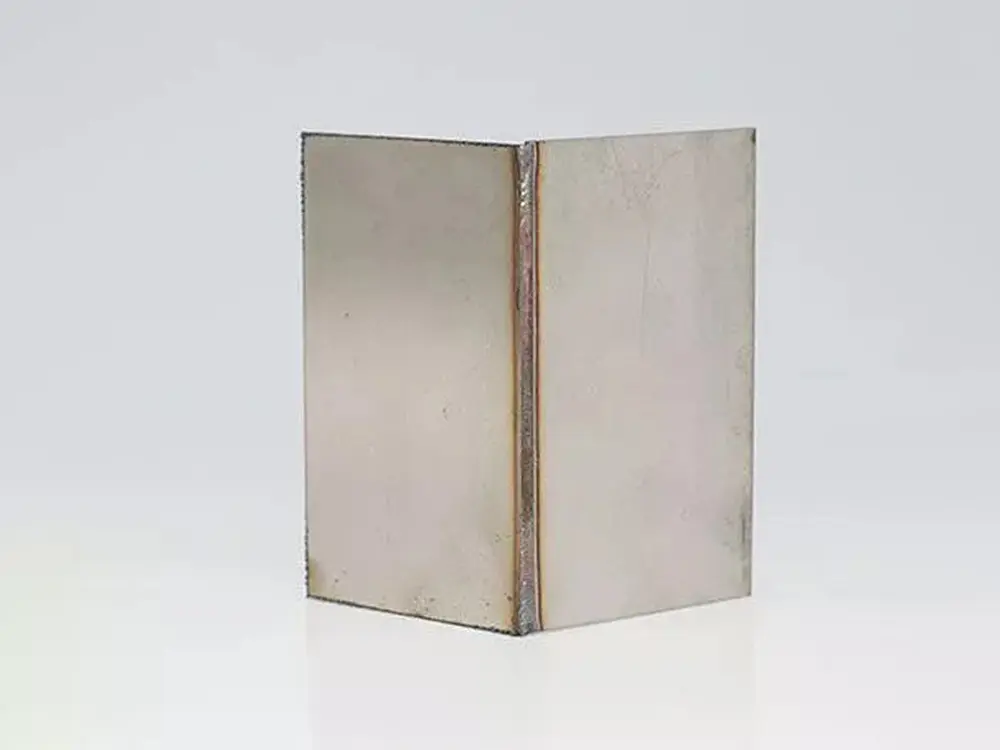

▍Air Cooled Handheld Laser Welding Machine Sample

▍Air Cooled Laser Welding Machine Configuration

Laser Source

The core component uses fiber laser technology, delivering stable and efficient laser output. It handles various materials such as carbon steel, stainless steel, and aluminum with adjustable welding depth and width. The laser ensures superior welding quality and consistency while being energy-efficient and cost-effective to operate.

Laser Welding Gun

The welding head features advanced optics and a high-precision focusing system, allowing quick focal adjustments as needed. It’s specially designed gas protection channel prevents oxidation in the welding area, ensuring smooth and robust welds. The lightweight design makes it easy to operate, even for challenging welding tasks.

Air-Cooling System

The integrated air-cooling system employs high-performance fans and heat exchange structures to dissipate heat without external cooling devices like water chillers. This design saves space, reduces maintenance and operational costs, and ensures stable performance during prolonged use, even in high-temperature environments.

Automatic Wire Feeder

The high-precision automatic wire feeder ensures uniform wire feeding into the welding area through an adjustable speed system. This minimizes welding defects and boosts efficiency. Compatible with various wire specifications, it is ideal for long seams and intricate welding tasks.

Portable Laser Welding Machine - Other Core Components

Multi Nozzles

Machine Body

Safety Goggles

Ground Clamp

▍Advantages of Air-Cooled Laser Welding Machine

1. Highly Portable: The air-cooled laser welding machine features a compact design, weighing only about 41 kg and occupying less than 0.11㎡. Equipped with a top handle and bottom wheels, it can be easily moved by a single operator, enabling quick transitions between work locations to meet mobility demands.

2. Efficient Cooling: The air-cooled system eliminates the need for additional chillers or compressors, using high-efficiency fans and heat exchange mechanisms for rapid cooling. It operates effectively in high-temperature environments, reducing equipment costs, minimizing maintenance needs, and enhancing overall reliability.

3. Energy-Efficient and Eco-Friendly: Its pure air-cooling design significantly reduces energy consumption and eliminates the need for refrigerants or water resources, aligning with modern industrial environmental standards. The high operational efficiency lowers long-term energy costs.

4. Exceptional Welding Performance: Powered by optimized fiber laser technology, the machine delivers high-speed welding, superior seam quality, and requires no consumables. It is suitable for a variety of materials, including carbon steel, stainless steel, and aluminum alloys, excelling in precision welding tasks for thin-wall materials and complex structures.

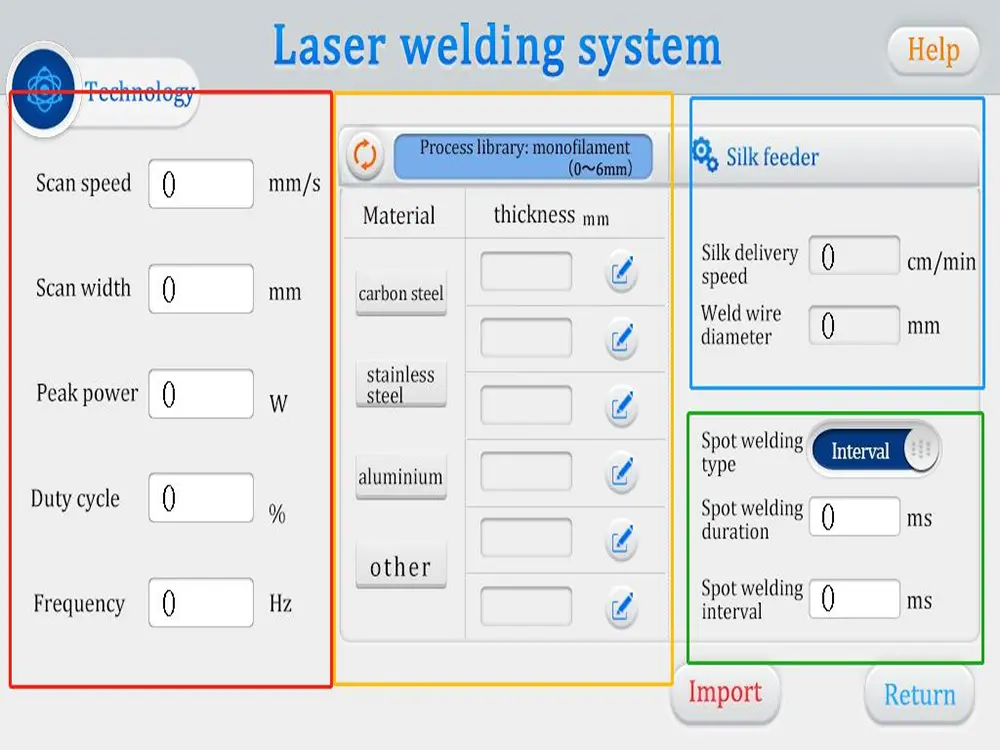

5. User-Friendly Operation: Equipped with a digital touch control panel and pre-set welding modes, the machine is easy to operate, even for beginners. Its control system supports real-time parameter adjustments, catering to various process requirements.

6. Low Maintenance Requirements: Compared to water-cooled machines, the air-cooled laser welding machine features a simplified structure without complex cooling components. This reduces maintenance costs, minimizes downtime, and boosts productivity.

7. Versatile Applications: Widely used in industries such as automotive, aerospace, electronics, and hardware manufacturing, the machine is adept at welding complex structures and hard-to-reach areas. Its adaptability meets the demands of high-standard industrial scenarios.

▍Handheld Fiber Laser Welding Machine FAQs

Q: What is the difference between air-cooled and water-cooled laser welding machines?

Air-cooled laser welding machines use advanced fans and heat exchangers to dissipate heat, eliminating the need for additional water chillers or refrigerants. This results in a more compact, portable design with lower maintenance costs, whereas water-cooled machines require larger cooling systems and higher operational costs.

Q: What are the benefits of the air-cooled system?

The air-cooled system offers several advantages, including enhanced portability, reduced energy consumption, and simplified maintenance. It is highly reliable and environmentally friendly, suitable for various working environments.

Q: What materials can be welded with an air-cooled laser welding machine?

The machine is suitable for a wide range of materials, including carbon steel, stainless steel, and aluminum. It excels in precision welding for thin-wall materials, complex structures, and high-strength alloys.

Q: What maintenance does an air-cooled laser welder require?

Due to its simplified air-cooling system, the machine requires minimal maintenance compared to water-cooled systems. Regular cleaning of the cooling fans and inspection of optical components ensure consistent performance.

Contact us now to explore our handheld laser welders. Fill out the form for a personalized quote.