▍Handheld Laser Welding Machine Description

The handheld laser welding machine is a highly efficient and versatile welding solution that leverages advanced laser technology for precision welding of various metal materials. Designed for ease of operation and process flexibility, it accommodates workpieces of all shapes and sizes, particularly suited for complex geometries and small-batch customized production. This equipment delivers smooth, uniform welds with significant depth and minimal heat-affected zones, reducing distortion and the need for extensive post-processing. Its ability to handle intricate welding tasks with high precision ensures exceptional results across diverse applications.

The ergonomic handheld design enhances portability and ease of use, allowing operators to work comfortably in various environments. It is widely used in the fields of automobile manufacturing, sheet metal processing, home appliance repair and decoration industries, and is an ideal alternative to traditional welding processes.

▍Handheld Laser Welder 1KW-3KW Parameters

| MODEL | WTW-1500 | WTW-2000 | WTW-3000 |

|---|---|---|---|

| Laser Welding Thickness | Carbon steel: 4mm Stainless steel: 4mm Aluminum: 2mm |

Carbon steel: 5mm Stainless steel: 5mm Aluminum: 3mm |

Carbon steel: 8mm Stainless steel: 8mm Aluminum: 5mm |

| Laser Power | 1500W | 2000W | 3000W |

| Operational Voltage | Single Phase 220V 50/60HZ | Single Phase 220V 50/60HZ | Three Phase 380V 50/60HZ |

| Laser Wavelength | 1080nm | 1080nm | 1080nm |

| Fiber Cable Length | 10-20m | 10-20m | 10-20m |

| Maximum Welding Speed | 0.5-120mm/s | 0.5-120mm/s | 0.5-120mm/s |

| Operating System | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Laser Welding Head | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Cooling System | Water cooling | Water cooling | Water cooling |

| Working Environment Temperature Range | 10-40℃ | 10-40℃ | 10-40℃ |

| Automatic Wire Feeder | √ | √ | √ |

| Laser Welding Machine Dimensions | 570*250*400mm | 570*250*400mm | 570*250*400mm |

| Laser Welder Machine Weight | 180KG | 180KG | 180KG |

| Laser Welding Gun Weight | 0.75kg | 0.75kg | 0.75kg |

| Consumable Parts | 10 pcs nozzles, 10 pcs protective lenses | ||

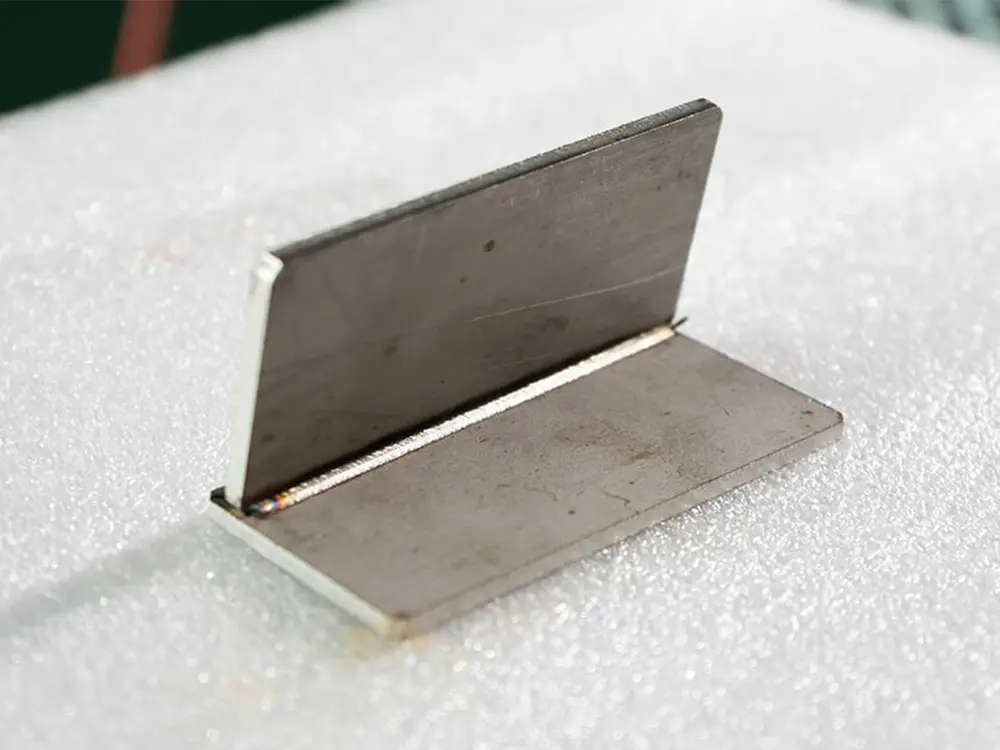

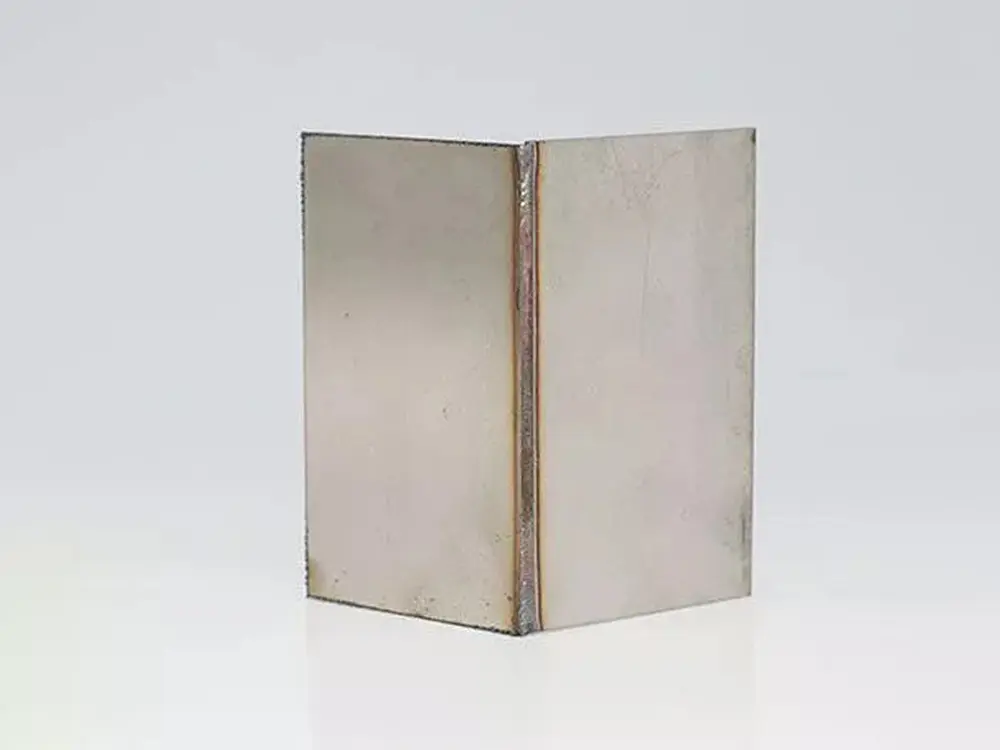

▍Handheld Metal Laser Welding Machine Sample

▍Metal Laser Welding Machine Configuration

Laser Source

The laser beam has a concentrated and high-energy density, enabling deep penetration welding and faster processing speeds. Fiber lasers provide power options from 1000-3000w to meet the welding needs of different thicknesses and materials.

Laser Welding Gun

-Narrow weld seam, good appearance quality.

-Large welding depth, can be used for thicker materials.

-Focusable beam, concentrated energy.

-Non-contact welding, avoid tool wear.

-Easy to control beam, precise welding position.

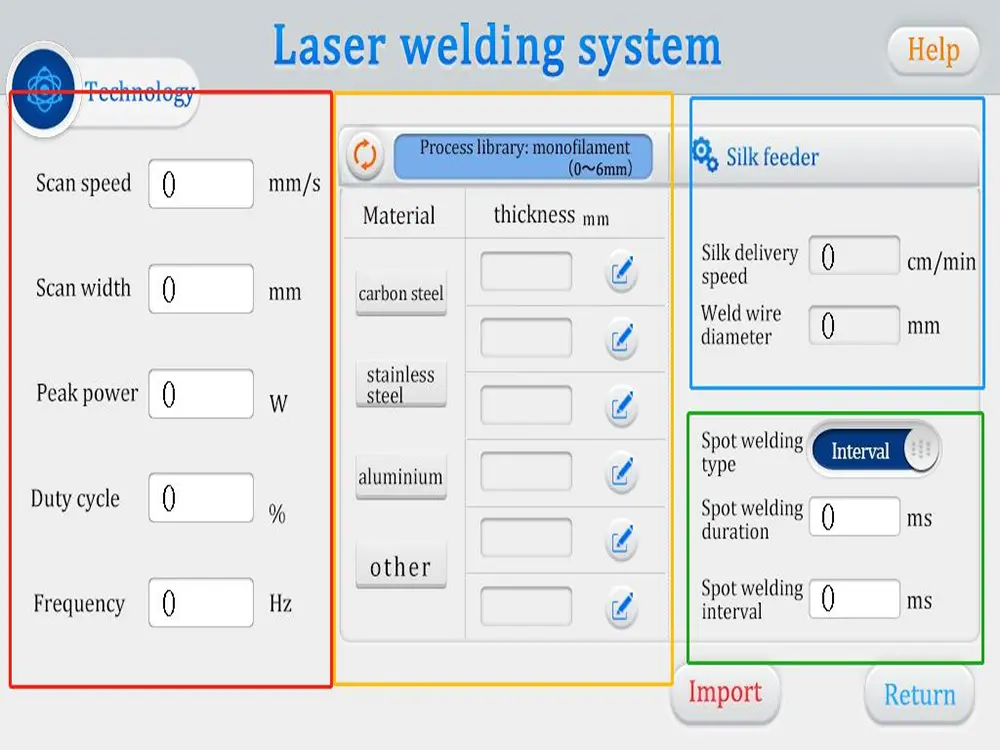

Easy Operation Software

Laser welding machine operating systems typically feature intuitive and easy-to-navigate interfaces that allow operators to quickly set up and control the machine. The software enables precise adjustment of laser power, welding speed, and focus position, ensuring high weld quality.

Automatic Wire Feeder

Adapt to a variety of welding wire specifications, and can be compatible with welding wires of different diameters and materials. High wire feeding accuracy, can accurately control the amount of welding wire delivered, and ensure stable welding quality.

Portable Laser Welding Machine - Other Core Components

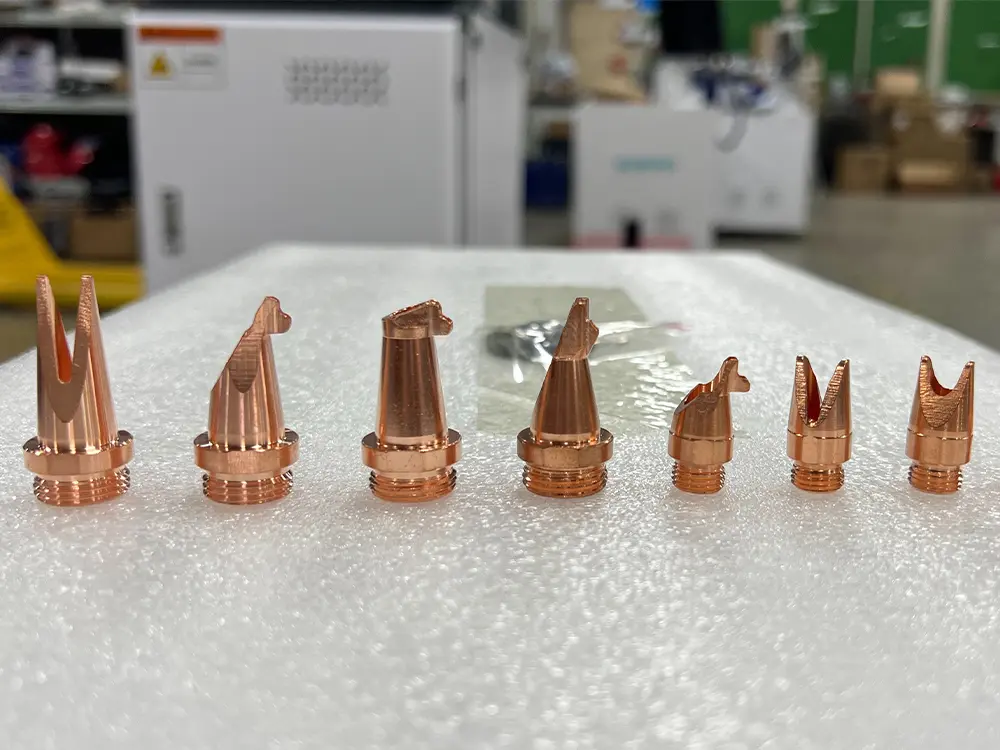

Multi Nozzles

Ground Clamp

Water Chiller

Safety Goggles

▍Handheld Laser Welding Machine Benefits

1. Portability and Flexibility: Compact and lightweight, ideal for various complex scenarios.

2. Ease of Operation: Intuitive handheld design, easy to use without extensive training.

3. High Welding Efficiency: Faster welding speed, 2-10 times that of traditional methods.

4. Superior Welding Quality: Fine and aesthetic welds with minimal thermal deformation.

5. Wide Application Range: Supports efficient welding of various metal materials.

6. Cost-Effective: Low energy consumption, minimal material waste, and reduced post-processing costs.

▍Handheld Fiber Laser Welding Machine FAQs

Q: Do handheld laser welding machines require gas?

Yes, handheld laser welders typically require shielding gases like argon or nitrogen. These gases protect the weld area from oxidation and contamination during the welding process, resulting in cleaner and stronger welds. The choice of gas can vary depending on the material being welded; for instance, argon is commonly used for stainless steel, while nitrogen is sometimes used for aluminum or titanium. Using shielding gas ensures higher weld quality, reduces defects, and improves overall efficiency.

Q: How much does a handheld laser welding cost?

The price of a handheld laser welder is usually between $2,000 and $5,000, depending on the hardware configuration and power of the device. For smaller-scale applications, lower-powered machines are more cost-effective, while industrial-grade models may cost more due to enhanced durability and advanced technology. Contact us for a customized quote based on your specific requirements.

Q: What materials can be welded with a handheld laser welder?

Handheld laser welding machines are widely used and can efficiently and precisely weld various metal materials, including carbon steel, stainless steel, aluminum, copper, galvanized steel, and titanium alloys.

Q: How do I maintain a handheld laser welding machine?

To maintain a handheld laser welding machine, clean the protective lenses, nozzles, and optical components regularly to prevent contamination and ensure beam quality. Check all cables and connectors for wear or damage, and inspect the water cooling system to ensure there are no leaks and it functions properly. Avoid running the machine at maximum power for extended periods to reduce stress on components, and always use recommended shielding gases and consumables. Regularly inspect and refill or replace the coolant in the water cooling system as needed, and schedule periodic maintenance checks by certified technicians to address potential issues early.

Contact us now to explore our handheld laser welders. Fill out the form for a personalized quote.