▍Metal Laser Welding Machine Description

Platform laser welding machines are advanced equipment designed for precise and efficient welding applications. They are equipped with high-performance laser sources that ensure excellent energy output, resistance to high temperatures, and extended service life. These machines are ideal for complex welding tasks requiring accuracy, speed, and stability. It is suitable for welding stainless steel, carbon steel, aluminum alloy, copper, galvanized sheet and other materials. It is used in electronic appliances, confidential accessories, automobiles, household appliances, metal processing and other industries.

These machines offer significant advantages, including fast welding speeds, deep penetration, minimal deformation, and aesthetically pleasing weld seams. Their specialized control systems enable a variety of welding modes, such as continuous spot welding, straight lines, and circular patterns, catering to diverse application needs. The inclusion of motorized translation stages ensures high repeatability and efficiency, making platform laser welding machines an excellent choice for high-volume and precision-driven projects.

▍Metal Laser Welding Machine 1KW-3KW Parameters

| MODEL | WTW-1500 | WTW-2000 | WTW-3000 |

|---|---|---|---|

| Laser Welding Thickness | Carbon steel: 8mm Stainless steel: 6mm Aluminum: 4mm |

Carbon steel: 10mm Stainless steel: 8mm Aluminum: 6mm |

Carbon steel: 15mm Stainless steel: 10mm Aluminum: 8mm |

| Laser Power | 1500W | 2000W | 3000W |

| Operational Voltage | Single Phase 220V 50/60HZ | Single Phase 220V 50/60HZ | Three Phase 380V 50/60HZ |

| Laser Wavelength | 1080nm | 1080nm | 1080nm |

| Fiber Cable Length | 10m | 10m | 10m |

| Maximum Movement Speed | 200mm/s | 200mm/s | 200mm/s |

| Operating System | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Laser Welding Head | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar | Sup Laser / Raytools / Relfar |

| Position Accuracy | 0.05mm | 0.05mm | 0.05mm |

| Repeatability Accuracy | 0.05mm | 0.05mm | 0.05mm |

| Cooling System | Water Cooling | Water Cooling | Water Cooling |

| Light Spot Adjustment Range | 0.1-5mm | 0.1-5mm | 0.1-5mm |

| Laser Frequency | 1-10000HZ | 1-10000HZ | 1-10000HZ |

| XYZ Travel | 800×300×300mm/500×300×300mm | 800×300×300mm/500×300×300mm | 800×300×300mm |

| Optional Components | servo/stepper motor, automatic wire feeding, rotating axis, machine head swing, extended stroke | ||

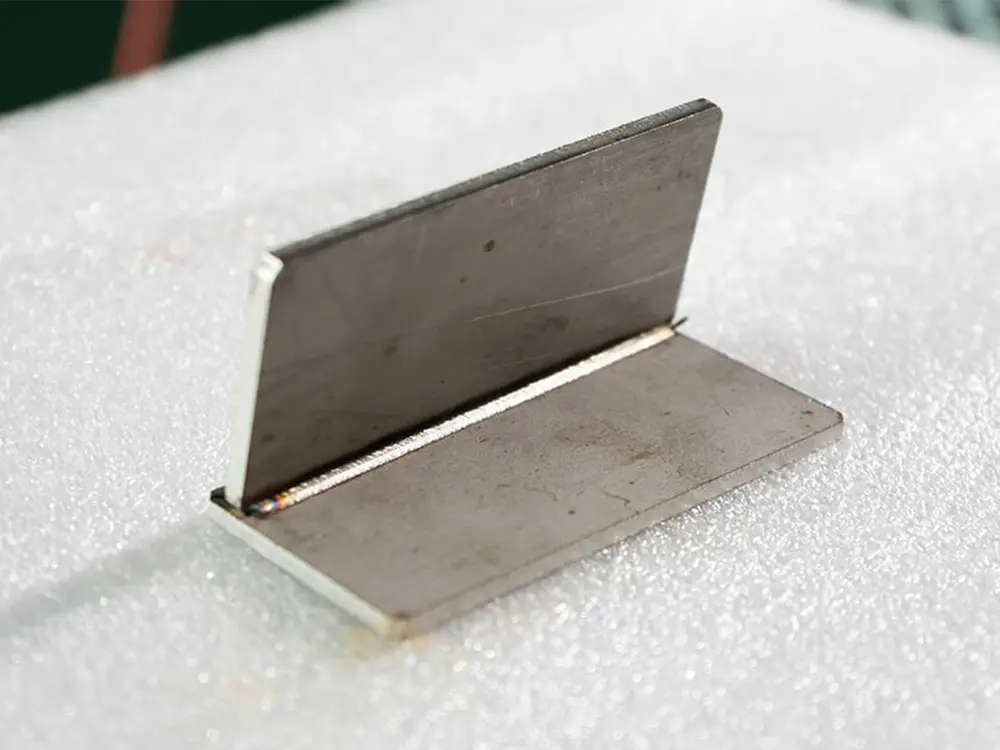

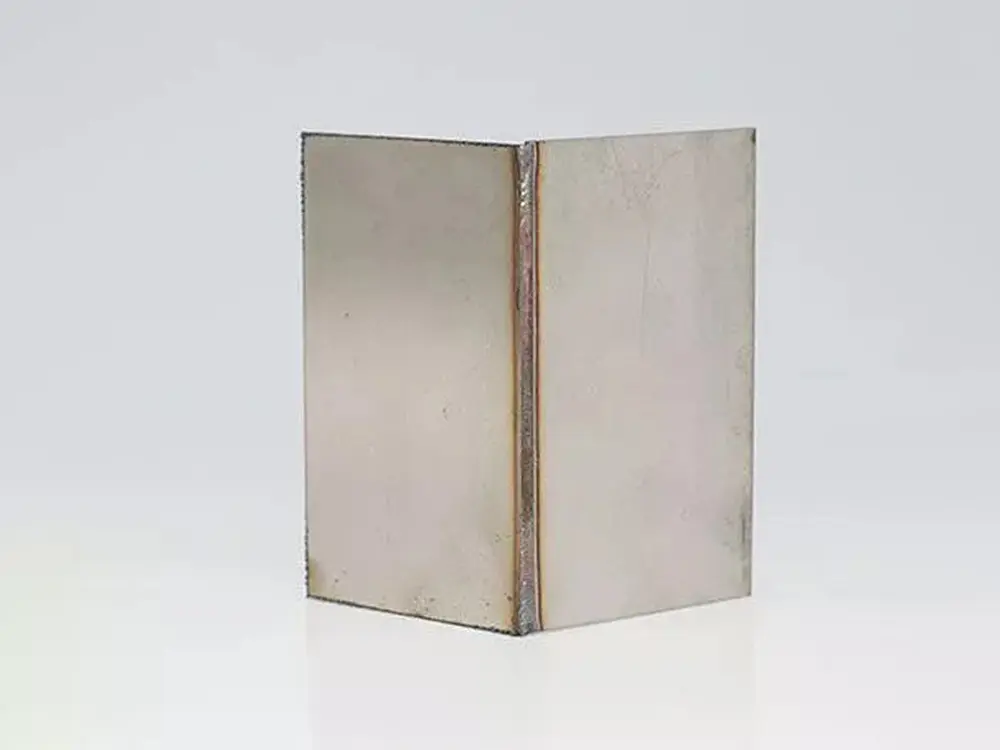

▍Metal Laser Welding Machine Sample

▍Metal Laser Welding Machine Configuration

CNC Three-Axis Moving Table (XYZ)

Controlled by advanced computer programming, it supports geometric spatial movements, allowing adaptability to a wide range of product shapes and sizes. Capable of following any welding path with precision and consistency, it enhances flexibility and accuracy in complex welding applications.

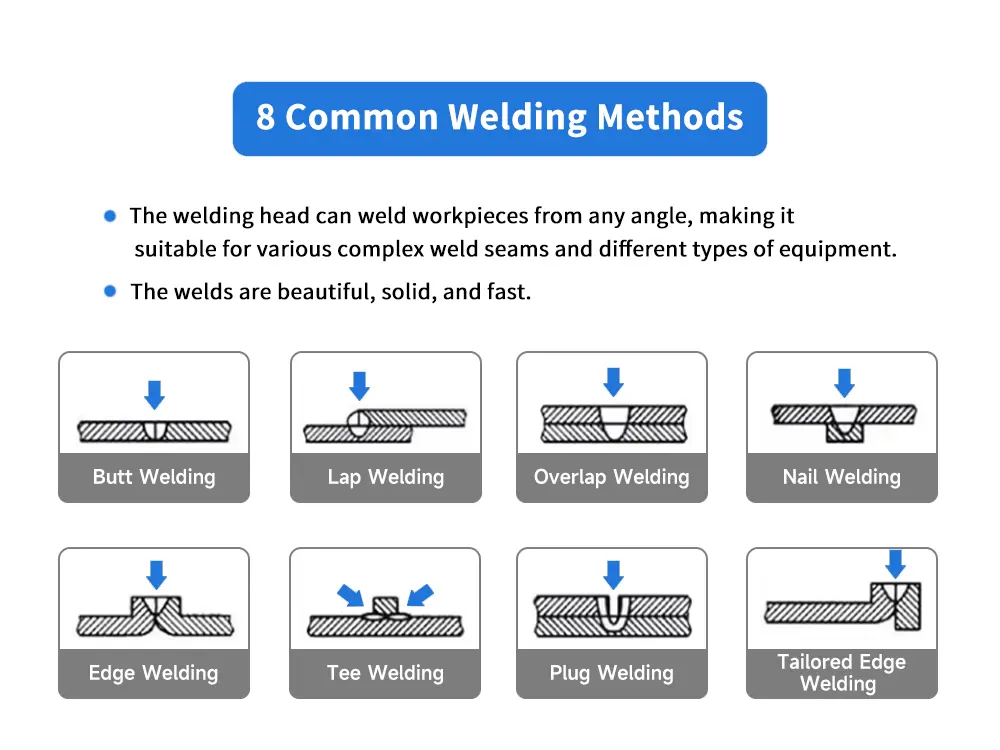

Welding At Any Angle

The welding head allows full 360° operation, offering exceptional versatility for complex weld seams and irregular shapes. Delivers high-quality, strong, and aesthetically pleasing welds, adaptable to a wide range of equipment and applications.

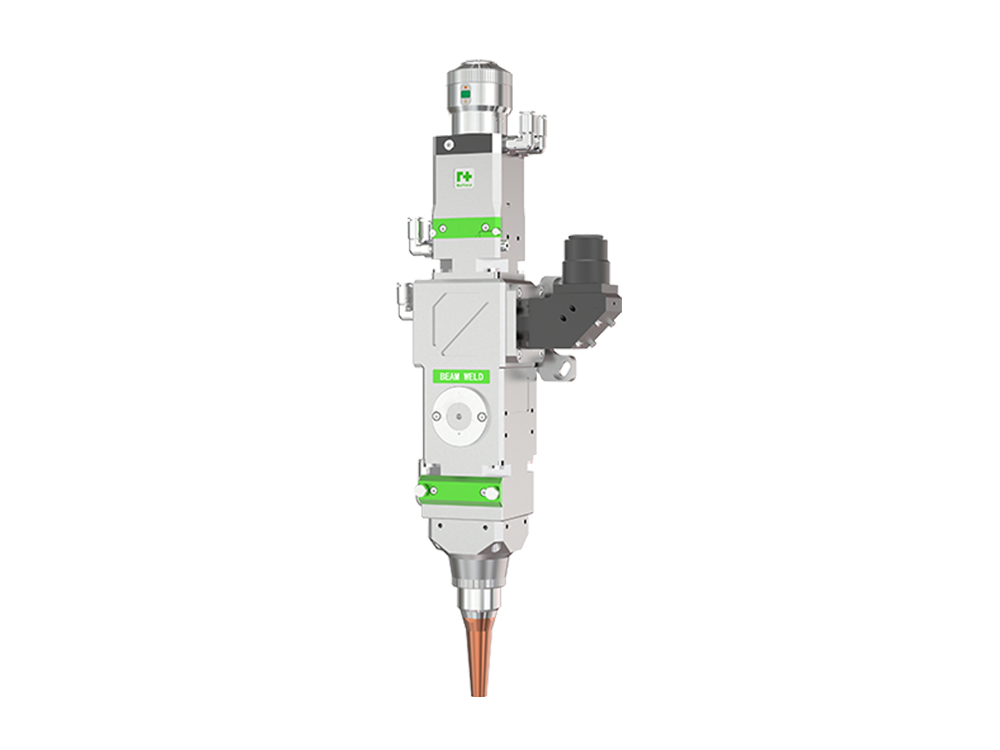

Dual-Swing Laser Welding Head

Provides exceptional flexibility for continuous and spot welding, ensuring precise control and consistent results. Delivers high welding strength, superior accuracy, and rapid operation. Suitable for various welding tasks, including intricate designs and complex seams, while maintaining uniform quality and efficiency.

Water Cooling System

The water cooling system of a laser welding machine maintains optimal temperatures for the laser source and critical components, ensuring stable and efficient operation. With built-in temperature sensors, safety mechanisms, and energy-efficient design, it provides reliable performance while minimizing operational costs.

Fiber Laser Welding Machine - Other Core Components

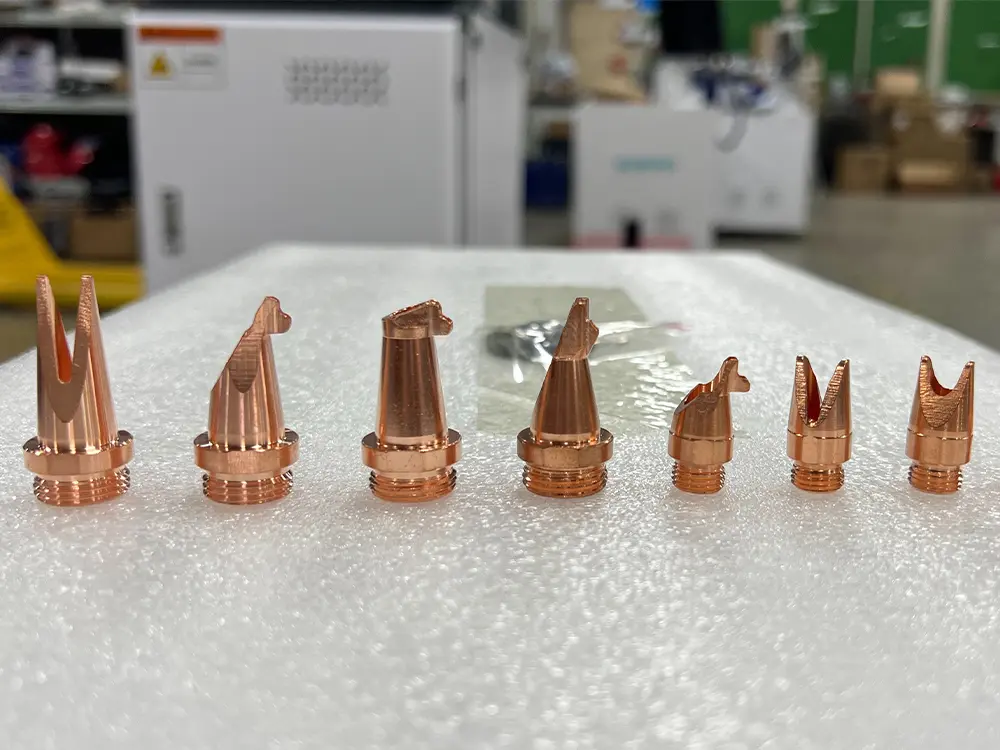

Multi Nozzles

Ground Clamp

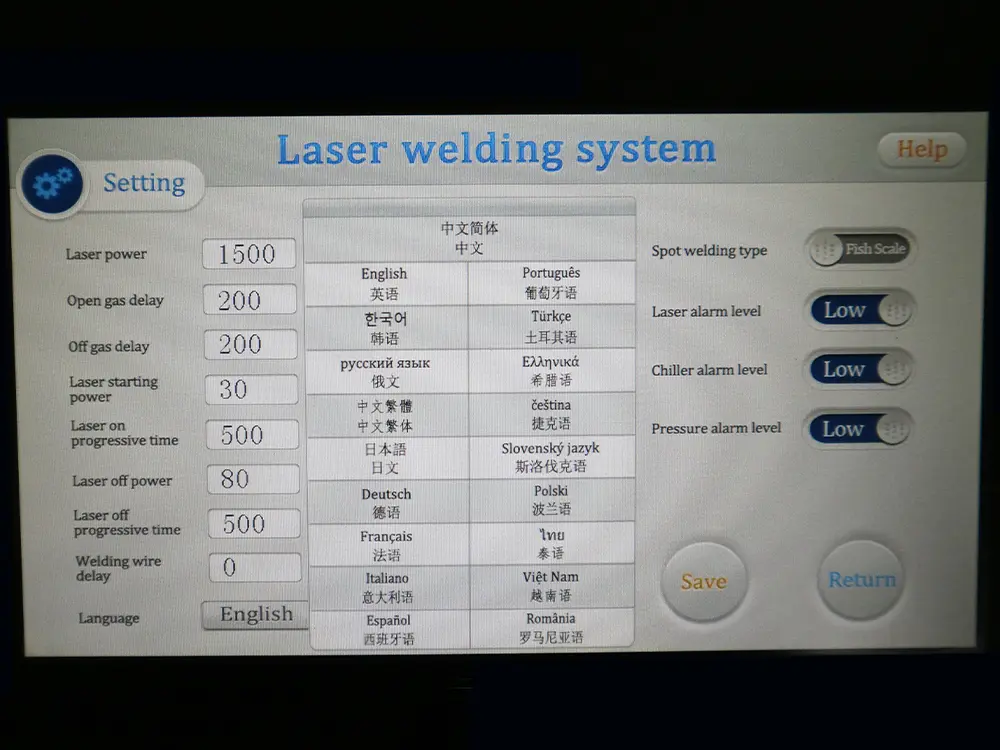

Laser Welding System

Safety Goggles

▍Best Laser Welding Machine Benefits

1. Equipped with a well-known brand laser source with high reflectivity, strong energy output, high temperature resistance and corrosion resistance to ensure an ultra-long service life.

2. Features a dual-temperature, dual-control dedicated chiller, providing enhanced stability for extended, high-power welding operations.

3. Delivers fast welding speeds, deep penetration, minimal deformation, aesthetically pleasing weld seams, and low material consumption.

4. Includes a specialized welding control system with high stability, ease of use, and support for various welding modes, including continuous spot welding, straight lines, circles, arcs, and programmable patterns.

5. Incorporates a motorized translation stage with high repeat positioning accuracy, fast welding speeds, and efficient processing performance.

▍Metal Fiber Laser Welding Machine FAQs

Q: What is the advantage of the dual-swing welding head?

The dual-swing welding head offers exceptional flexibility and control, allowing for both continuous and spot welding. It enhances precision and consistency, producing strong, aesthetically pleasing welds. This design also enables the machine to handle complex and irregular welding paths with ease, making it versatile for a wide range of applications.

Q: Why does a platform laser welding machine need a CNC-controlled multi-axis motion system?

The CNC-controlled multi-axis motion system is a crucial component of a platform laser welding machine, enabling flexible welding operations in three-dimensional space and meeting the demands of complex welding paths. With precise numerical control, the multi-axis system ensures smooth operation and high accuracy, making it especially suitable for workpieces requiring intricate weld designs. Additionally, this system supports pre-programmed path operations, achieving automated welding processes to boost efficiency.

Q: What are the differences between platform laser welding machines and handheld laser welding machines?

Platform laser welding machines are ideal for high-precision and large-scale production, focusing on automation and consistency. In contrast, handheld laser welding machines offer greater flexibility, making them suitable for small-scale, diverse, or on-site welding tasks.

Q: What geometric shapes can a platform laser welding machine weld?

The platform laser welding machine can weld a variety of geometric shapes, including flat surfaces, curved surfaces, circular, square, and irregular shapes. The combination of a multi-axis motion system and a rotary worktable allows it to handle complex welding requirements effectively.

Contact us now to explore our metal welding machines. Fill out the form for a personalized quote.