Fiber Laser Cutting Video On Youtube

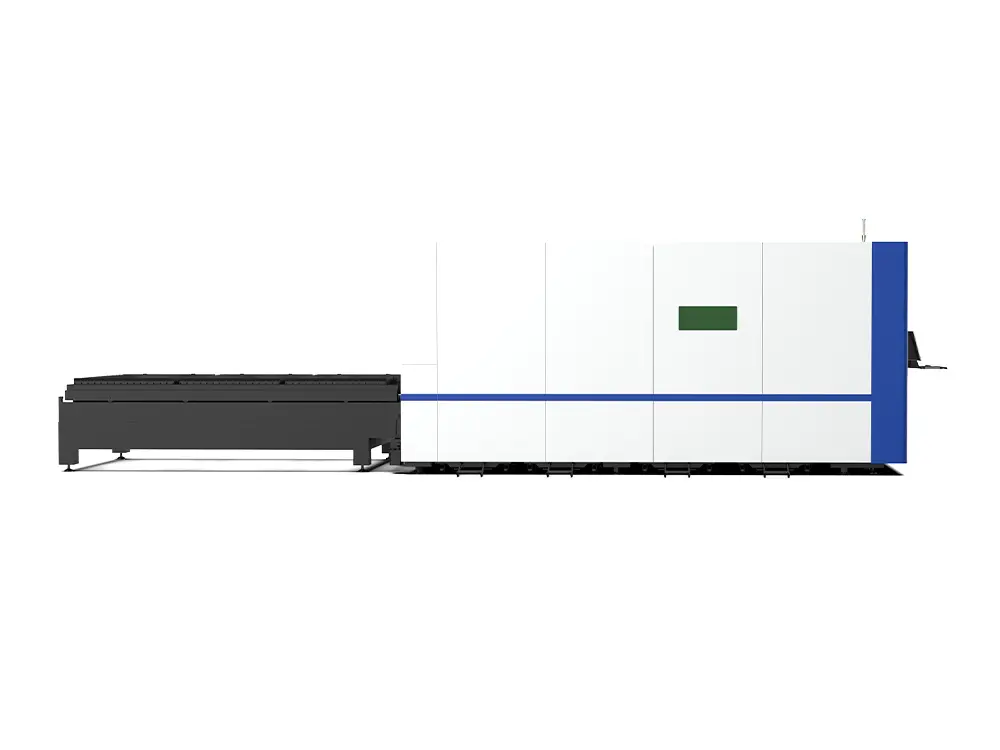

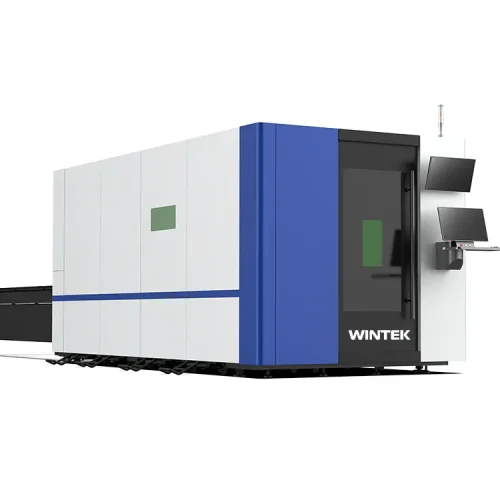

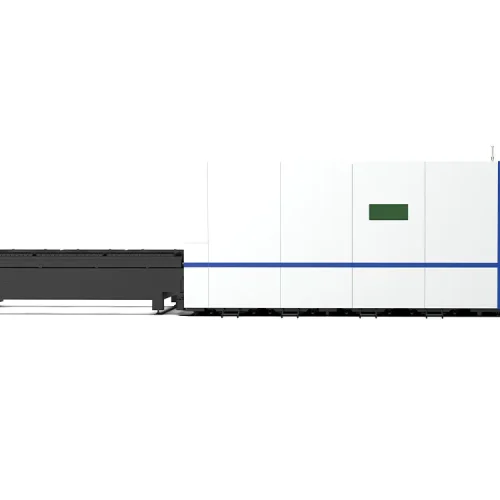

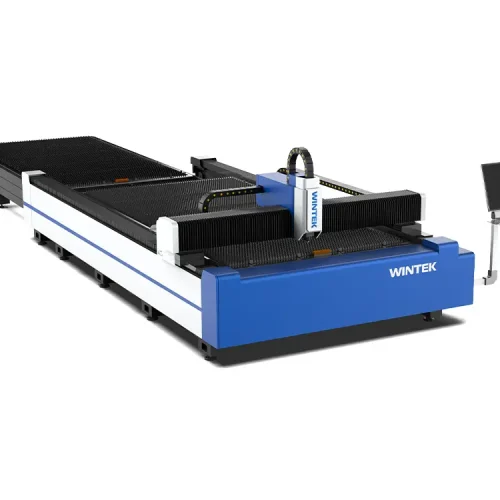

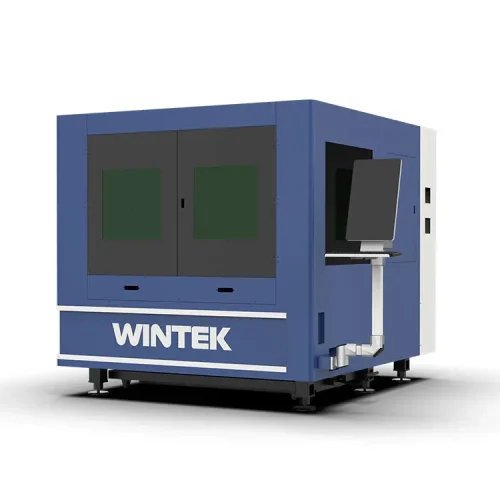

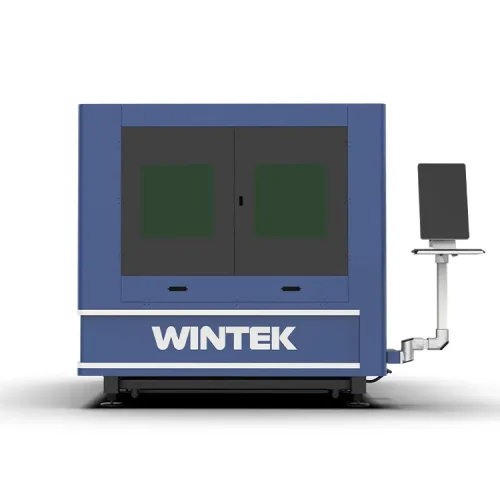

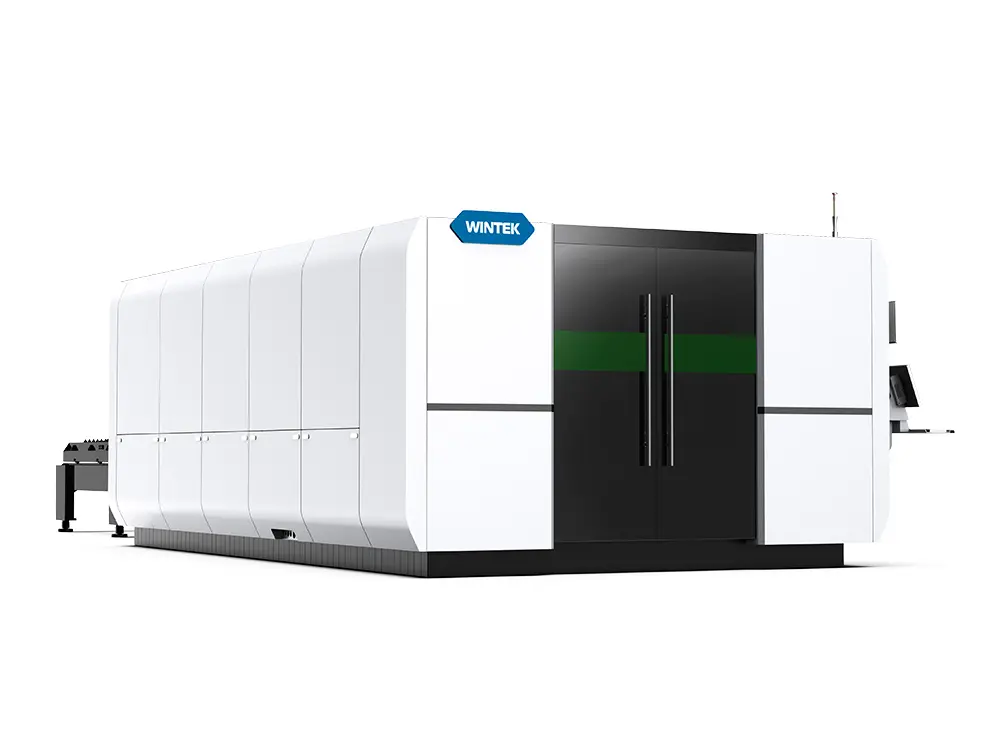

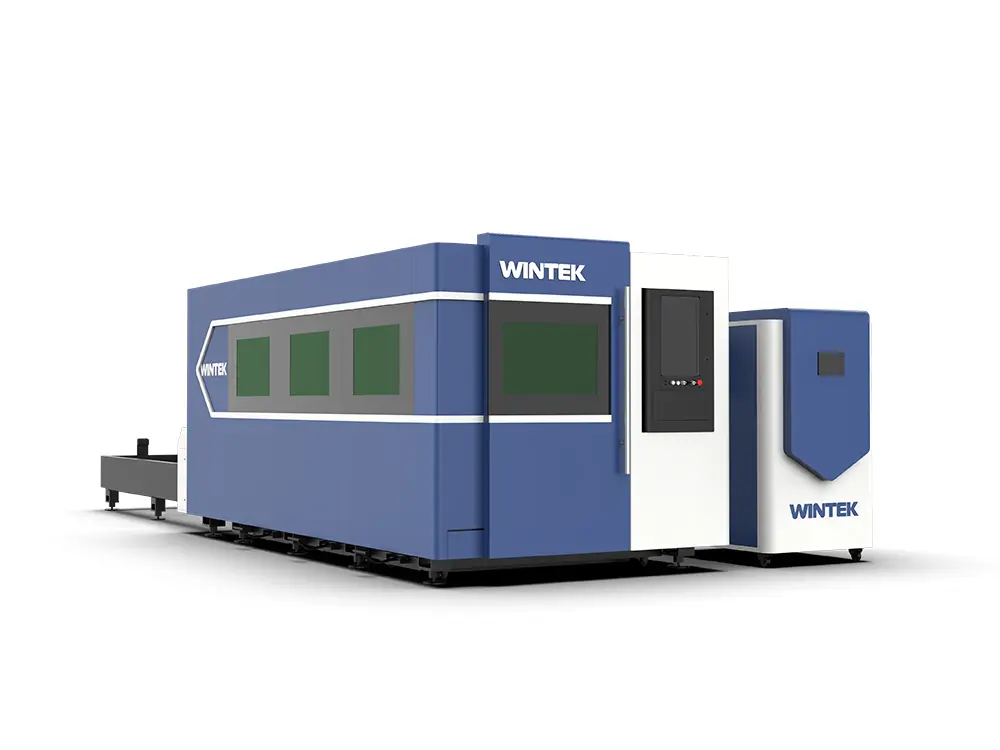

Enclosed Fiber Laser Cutting Machine Description

This is a closed fiber laser cutting machine with double worktables. It has an automatic switching worktable that can load and unload materials simultaneously while the cutting operation is in progress, which greatly reduces downtime and improves production efficiency. The machine is equipped with a fiber laser source, with fast cutting speed and high precision, and is capable of processing a variety of metal materials, including stainless steel, carbon steel, aluminum, etc. The machine is very suitable for small-scale and large-scale production, which can improve productivity and ensure excellent cutting quality.

1) Laser power: 1KW – 30KW

2) High-performance qualified fiber generator with high reliability and a maximum life of more than 100,000 hours.

3) Faster cutting speed and higher efficiency, with a maximum cutting speed of up to 150m/min.

4) Smooth cutting surface, small deformation and flat appearance.

5) Servo motor: Japan Yaskawa/Japan Fuji/China Inovance/China Delta, etc.

6) System: FUSCUT/Raytools, etc.

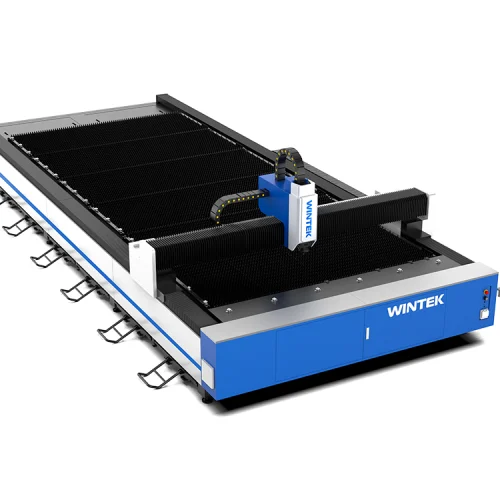

Different Design Variations of the WT3015P:

Technical Parameters

Below is a summary of the key specifications for the enclosed fiber laser cutting machine, highlighting its performance metrics. It is designed for precision and efficiency and is an ideal solution for various industrial cutting needs.

| WTP Series Enclosed Fiber Laser Cutting Machine | |||||

| Model | WT3015P | WT4020P | WT6020P | WT6025P | WT8025P |

| Working Area | 3000*1500 | 4000*2000 | 6000*2000 | 6000*2500 | 8000*2500 |

| Worktable Bearing Capacity | 1250kg | 1650kg | 2500kg | 3050kg | 3500kg |

| Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Repeat Positioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Acceleration | 1G-2.5G | 1G-2.5G | 1G-2.5G | 1G-2.5G | 1G-2.5G |

| Max. Exchange Time | 10-15s adjustable | 10-15s adjustable | 10-15s adjustable | 10-15s adjustable | 10-15s adjustable |

| Laser Power | 1000W-30000W | ||||

| Running Speed | 80-140m/min | 80-140m/min | 80-140m/min | 80-140m/min | 80-140m/min |

| Machine Bed | Plate welding bed | Plate welding bed | Plate welding bed | Plate welding bed | Plate welding bed |

Fiber Laser Cutting Machine Sample

Machine Configuration

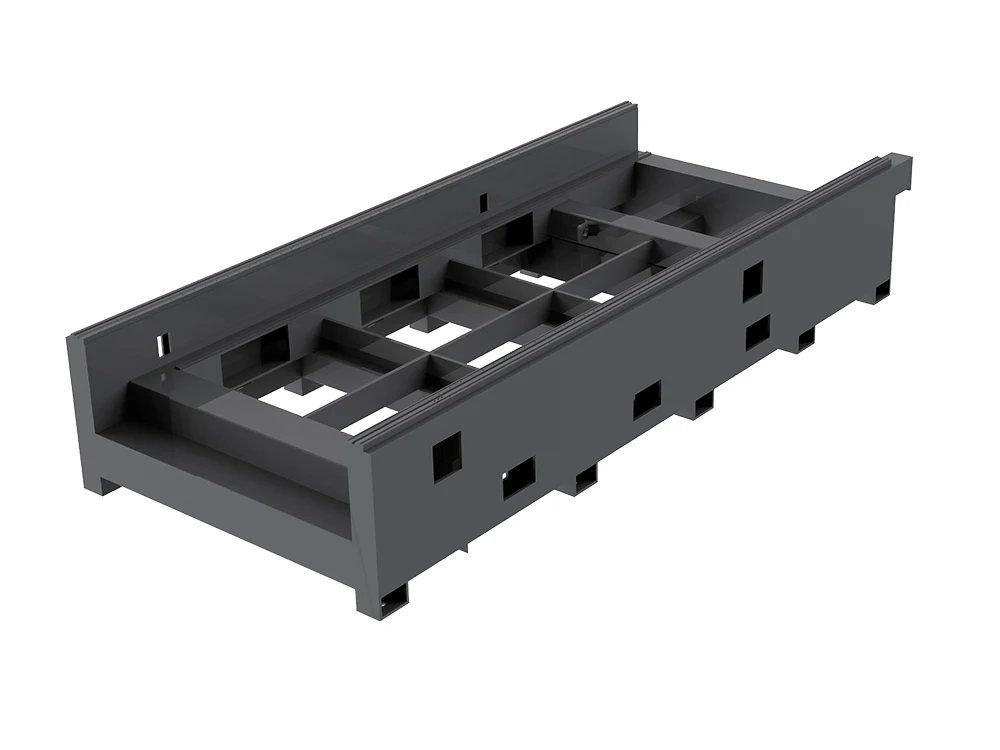

Strong and Stable Structure Table

The heavy-duty bed uses high-quality carbon structural steel, which is heat treated at 600℃ for 8 hours, then dried and cooled over 24 hours. After stress relief annealing, rough machining, and vibration aging treatment to eliminate welding.

Fully Enclosed Protective Cover

The fully enclosed design effectively isolates high-intensity laser beams, preventing harm to operators while also containing metal splashes during the cutting process to protect the environment and equipment. Additionally, the enclosed design reduces maintenance and improves overall performance by maintaining a clean environment.

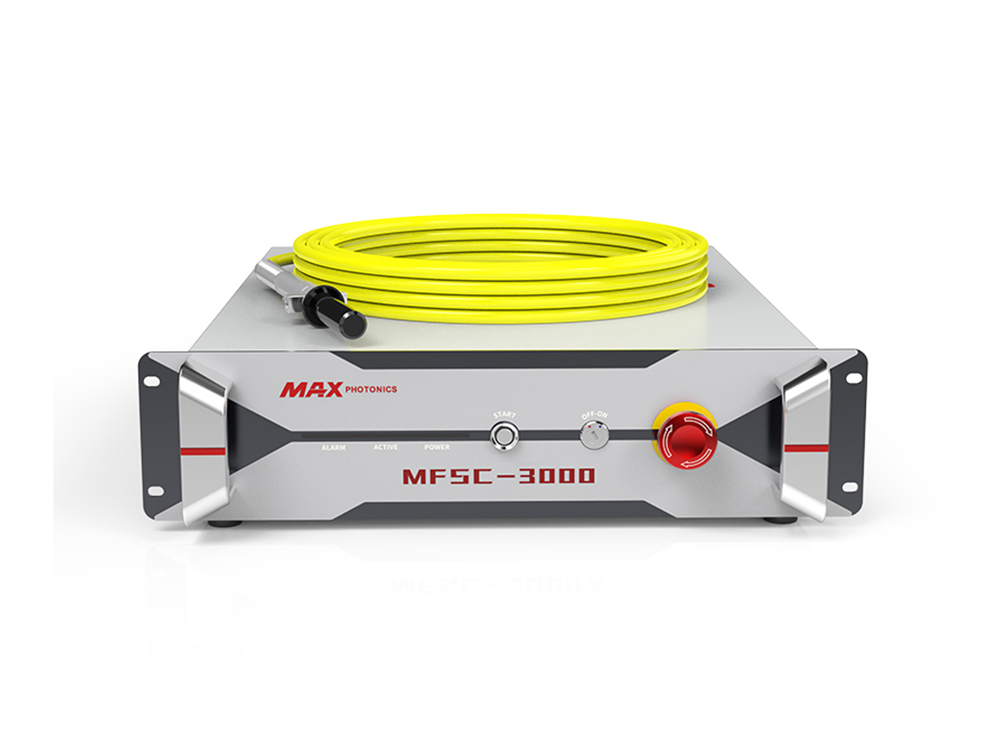

Fiber Laser Source

Fiber laser is the core component of the machine, delivering high-powered, stable, and efficient laser output. It is designed for exceptional energy efficiency, low maintenance, and long lifespan. This advanced laser source ensures precise cutting, minimal heat-affected zones, and clean edges.

Auto Focus Laser Cutting Head

Optimize the optical design to focus the laser energy on the cutting point to the maximum extent, reduce energy loss and reduce processing costs. Equipped with an anti-collision device, it can stop or retract in time to protect the cutting head and equipment from damage.

Fiber Laser Cutting Machine - Other Core Components

Aviation Aluminum Beam

Intelligent Operating System

Japan SHIMPO Reducer

Taiwan Hiwin Rails & YYC Gears

Fiber Optic Laser Cutter Benefits

Fiber laser cutting machines for sheet metal come in two main types: enclosed and open. The key difference lies in the design—enclosed machines feature a protective metal casing, while open machines lack this cover. Open machines typically have a single loading table and are more cost-effective. However, enclosed machines are generally equipped with dual loading tables, offering higher processing efficiency and enhanced safety. So, what are the advantages of enclosed fiber laser cutting machines?

1) Standard Exchange Platform: Equipped with a specialized exchange platform, these machines offer fast switching, convenient loading and unloading, and simultaneous sheet cutting and material handling.

2) Intelligent CNC System: The system supports one-click start, user-friendly human-machine interaction, intelligent edge detection, and automatic positioning. It allows importing various file types, intelligent nesting, automatic sequencing, process visualization, and simple operation.

3) European Standard Protective Cover: The enclosed design includes a protective cover that meets European standards. It filters and processes fumes and dust generated during cutting, ensuring compliant emissions.

4) Auto-Focusing Cutting Head: The fiber cutting head features a built-in motor drive, enabling programmed continuous focus adjustment for fast thick-plate piercing and seamless cutting across various thicknesses and materials.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.