Fiber Laser Cutting Video On Youtube

CNC Fiber Laser Cutting Machine Description

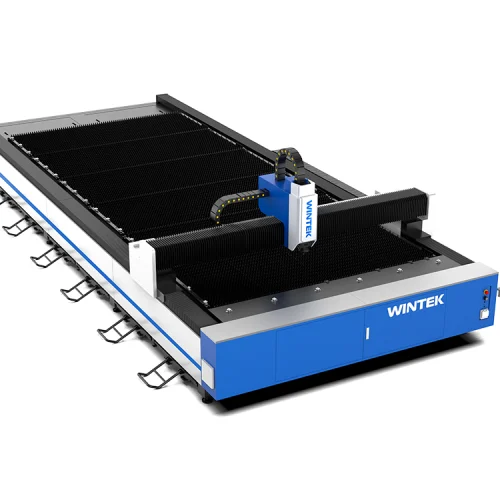

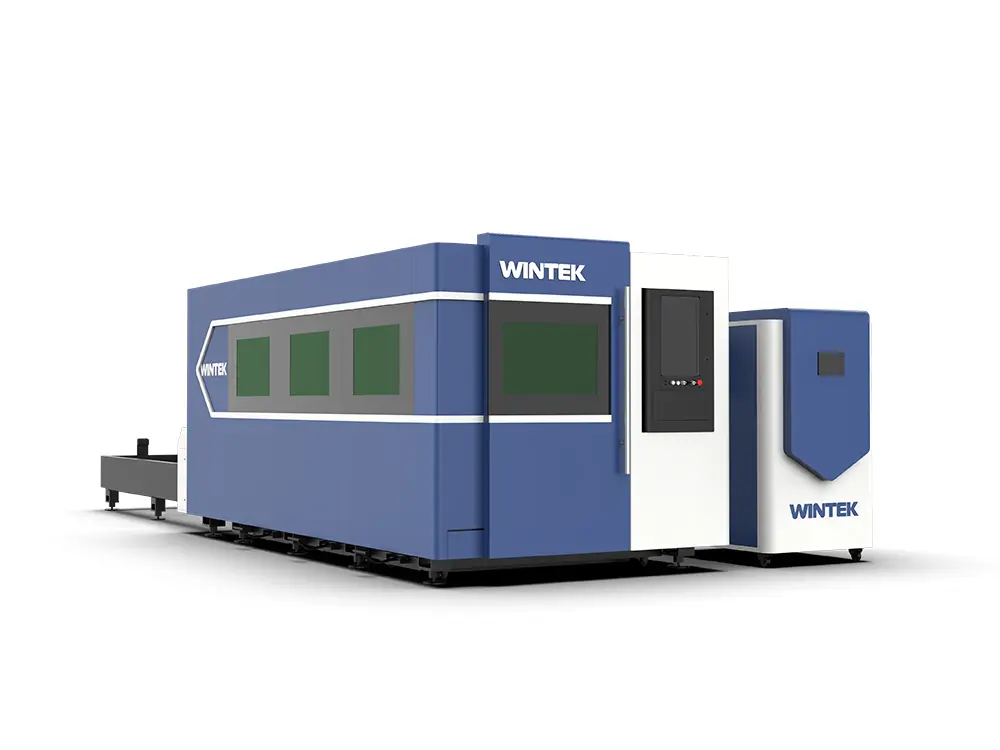

Wintek cnc fiber laser cutting machine is known for high efficiency, precision, large aperture, and wide applicability, and has become an indispensable equipment in the metal processing and manufacturing industry. Its robust structure ensures stability, durability, and consistent performance under demanding conditions. Equipped with a powerful fiber laser source, which ensures energy efficiency and low maintenance costs. Advanced software and control systems allow for easy operation and optimized cutting paths. It not only improves production efficiency but also ensures cutting quality, especially suitable for batch cutting.

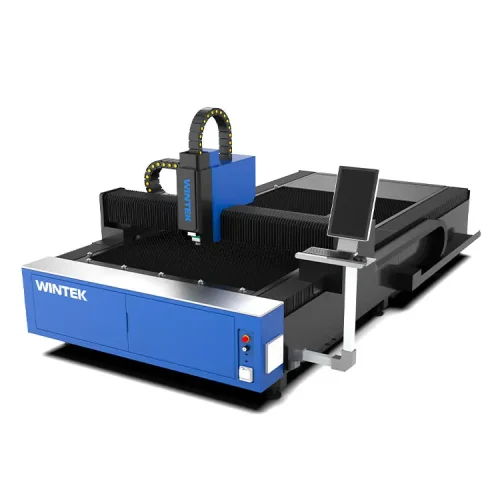

The WT3015A metal laser cutting machine features a spacious 3000mm x 1500mm cutting area, ensuring ease of operation and a high degree of automation. It features an open platform design and supports sheet thicknesses from 0.5 mm to 20 mm, meeting basic cutting needs with precision and reliability. Its versatility makes it suitable for various industries, including machinery manufacturing, automotive production, advertising, and metal processing.

UPGRADE SERIES

AE – series

The fiber laser cutting machine features a 10-15s exchange platform, enabling rapid material changes to boost productivity and minimize downtime.

DETAILS

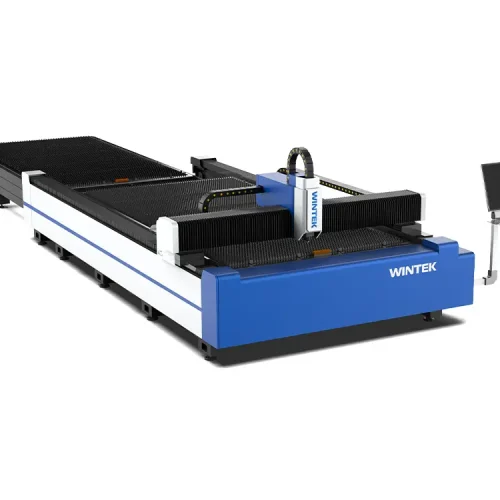

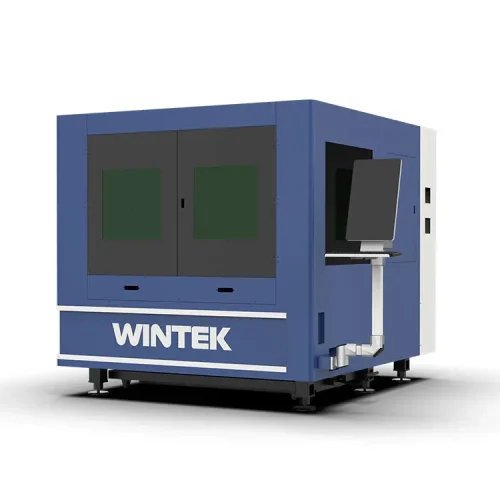

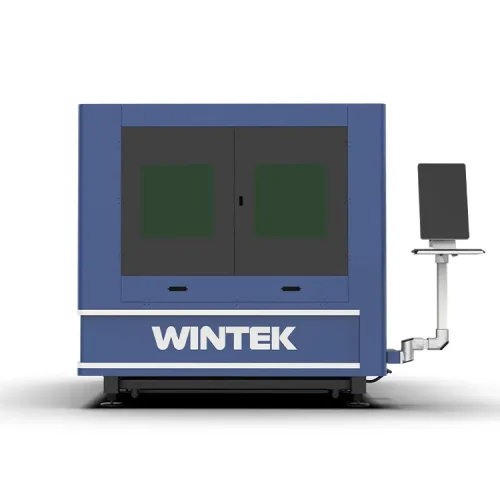

AT – series

This fiber laser cutting machine can cut sheets and tubes, combining two functions in one to save costs. It can cut plates up to 35mm thick and pipes up to 6m/350mm.

DETAILS

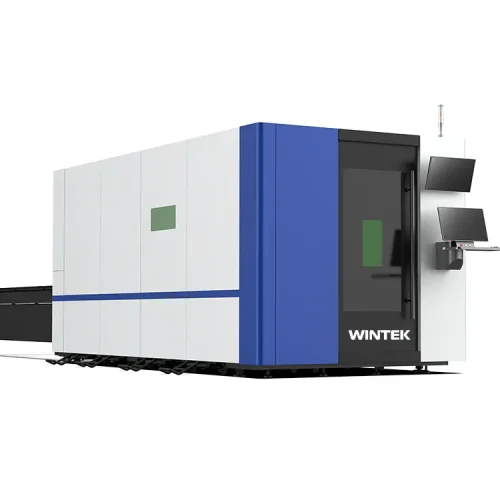

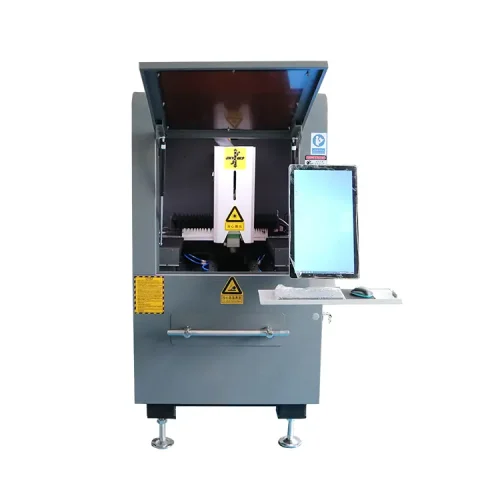

P – series

The fully enclosed fiber laser cutting machine ensures maximum safety, reduced noise, and improved efficiency, making it ideal for high-precision industrial applications.

DETAILSTechnical Parameters

Below is a summary of the key specifications for the fiber laser cutting machine, highlighting its performance metrics. It is designed for precision and efficiency and is an ideal solution for various industrial cutting needs.

| Product Name | WT3015A |

| Fiber Laser Power | 1KW-30KW |

| Laser Wave Length | 1064nm |

| Cutting Speed | 80-140 m/min |

| Fiber Laser Lifespan | More than 100000 hours |

| Auxiliary Gas | oxygen, nitrogen, compressed air |

| Repeatability Accuracy | 0.03mm |

| Position Accuracy | 0.02mm |

| Cutting Head | Automatic focus cutting head |

| Electrical Components | France Schneider |

| Working Voltage | 380v, 3phase, 50hz/60hz (customized) |

| Acceleration | 0.8G-2.5G |

Fiber Laser Cutting Machine Sample

Machine Configuration

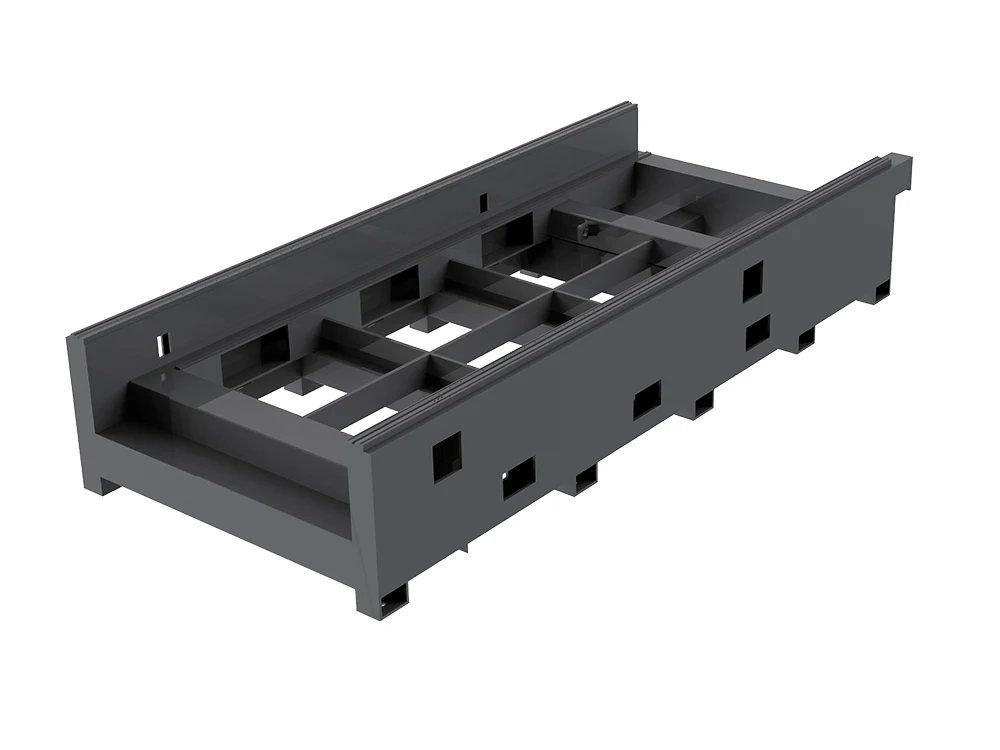

Heavy-Duty Steel Welded Bed

Wintek bed adopts plate welding design and uses high-rigidity materials to ensure that the bed does not deform during high-speed, high-power laser cutting, providing stable cutting performance. The high-precision bed manufacturing process ensures the accuracy of the cutting machine.

Aviation Grade Tensile Aluminum Beam

Made from premium aerospace aluminum, it offers excellent rigidity and stability during high-speed operations. The beam is processed by T6 heat treatment, which can obtain the highest strength and strong deformation resistance.

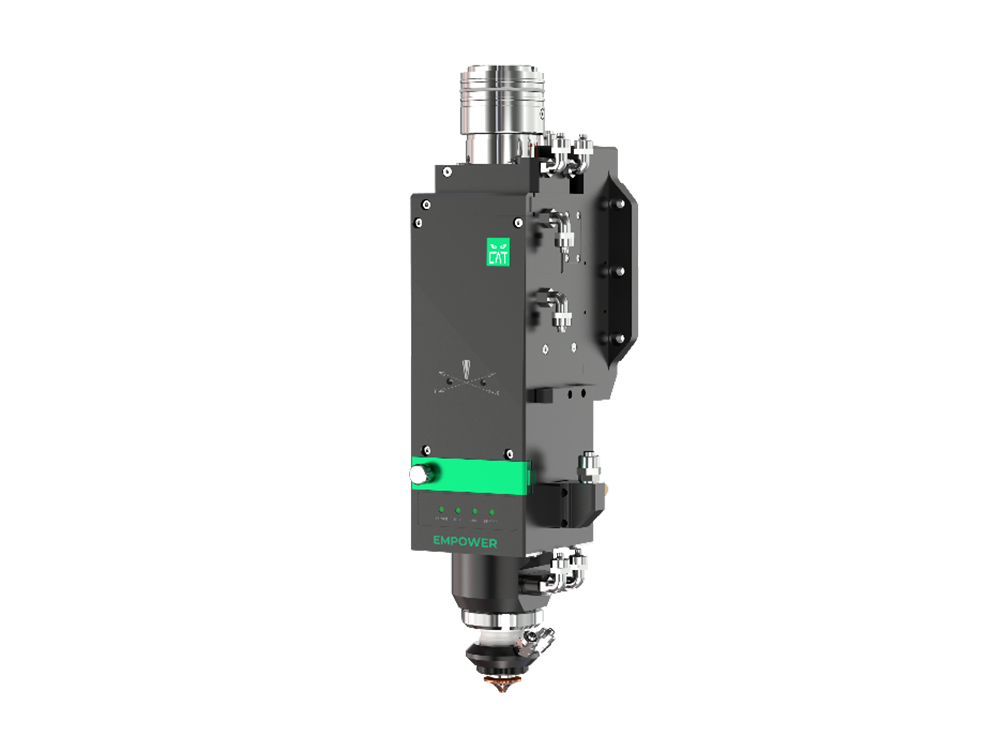

Laser Cutting Head

The cutting head has intelligent detection and feedback functions, which can monitor the cutting status in real time, such as power, temperature, etc. Then the information is fed back to the control system so that the parameters can be adjusted in time.

Intelligent Operating System

With its intuitive interface, even beginners can operate it easily. The system supports multiple file formats, ensuring seamless compatibility with various fiber laser cutting machines. It optimizes cutting accuracy, speed, and overall productivity, making it an essential tool for efficient manufacturing.

Fiber Laser Cutting Machine - Other Core Components

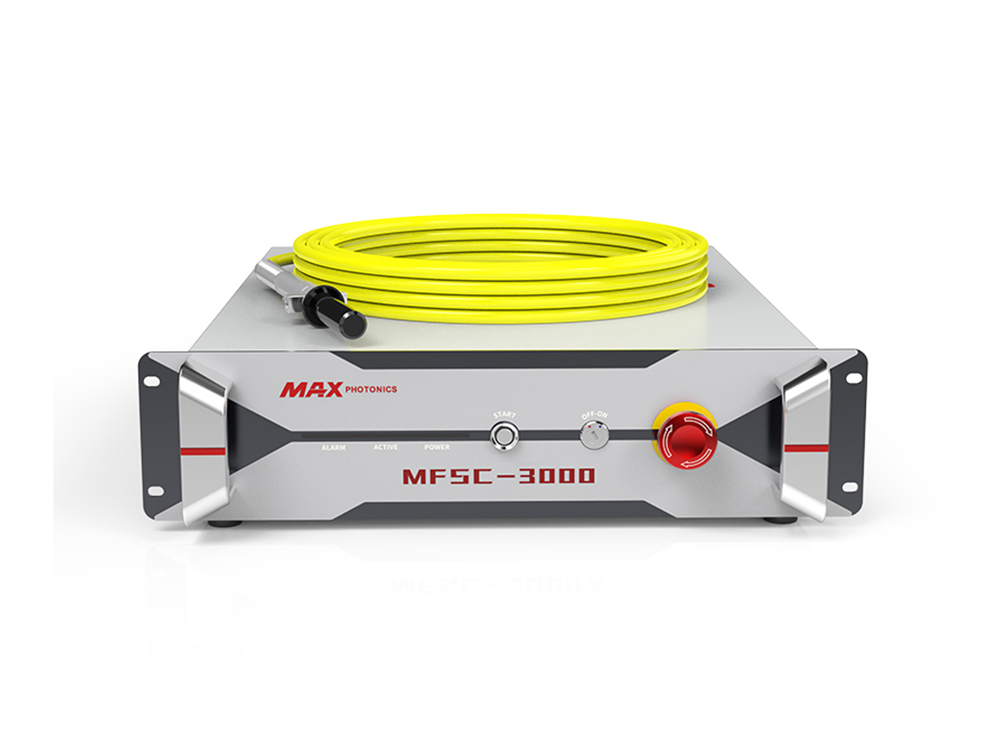

Fiber Laser Source

Taiwan Hiwin Rails & YYC Gears

Water Chiller

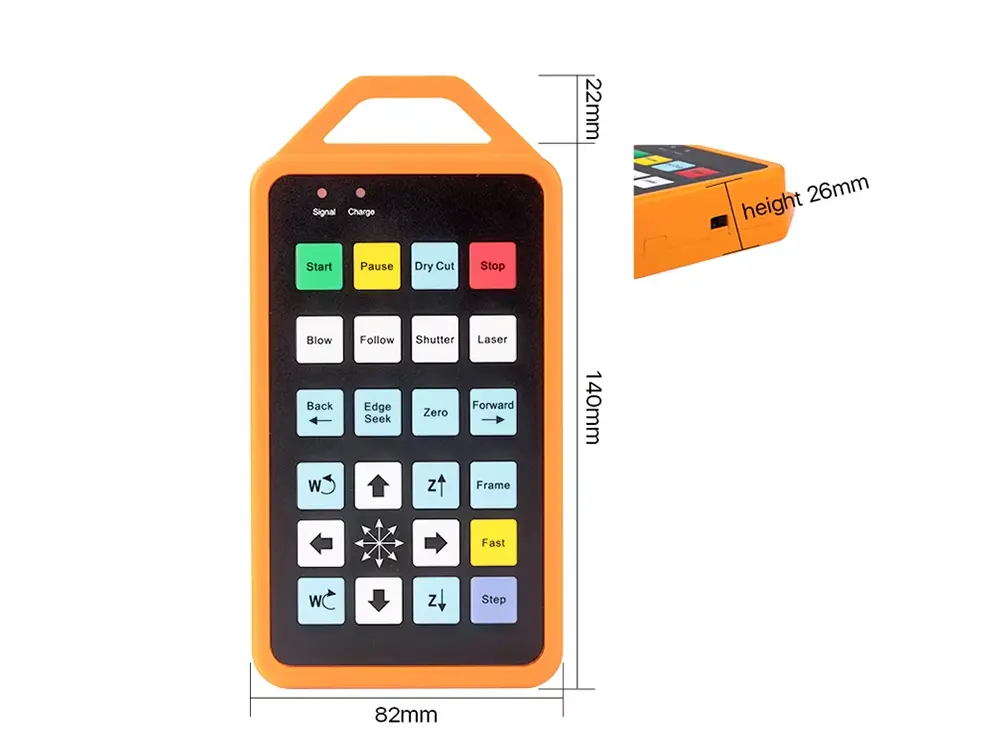

Wireless Handheld Control

Fiber Optic Laser Cutter Benefits

1. High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cut surface without burrs.

2. The laser cutting head does not contact the surface of the material and will not scratch the workpiece.

3. The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

4. Good processing flexibility, can process any graphics, and can also cut pipes and other special-shaped materials.

5. Can cut steel plates, stainless steel, aluminum alloy plates, cemented carbide and other materials of any hardness without deformation.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.