Fiber Laser Cutting Video On Youtube

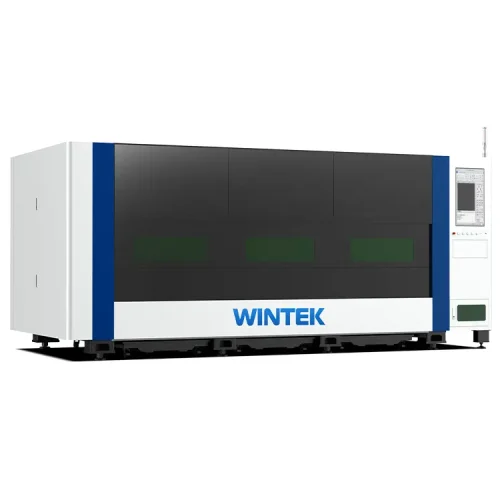

▍Fiber Laser Metal Cutting Machine Description

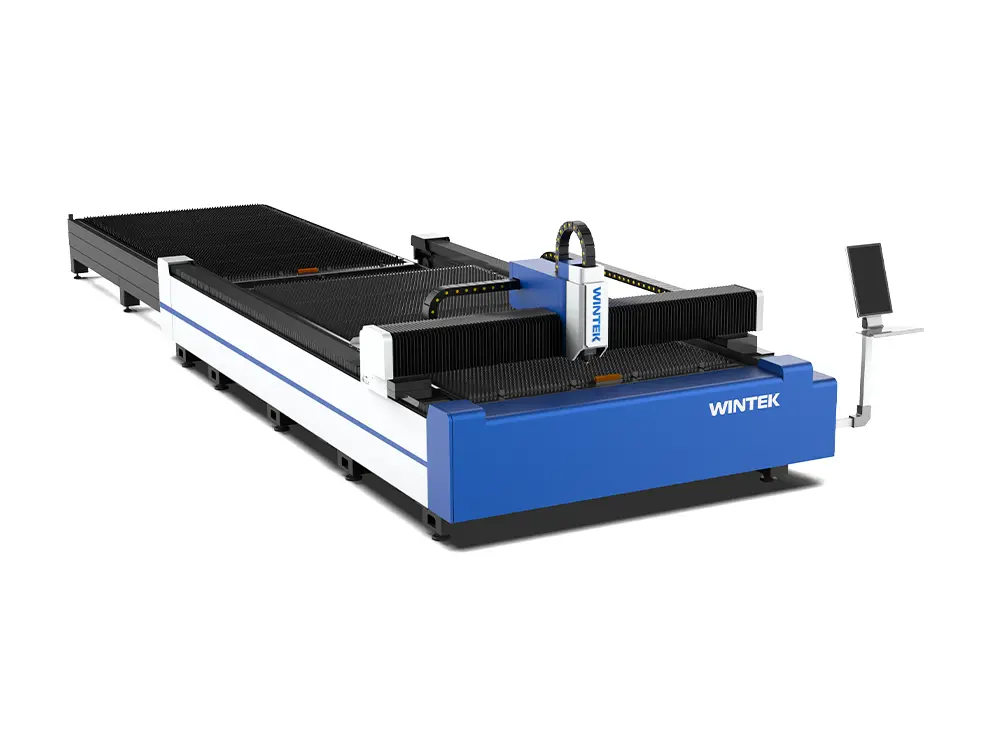

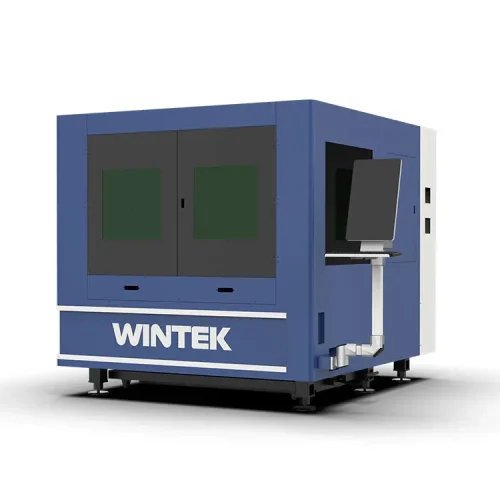

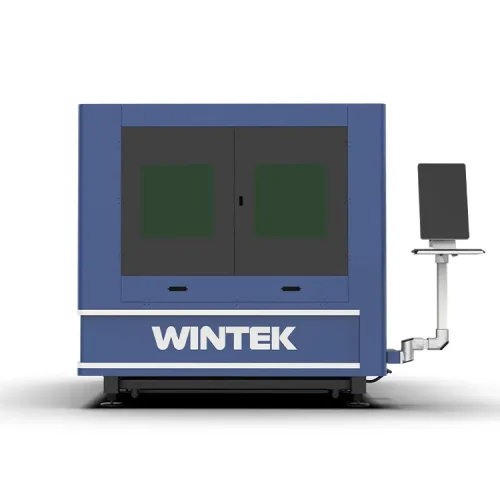

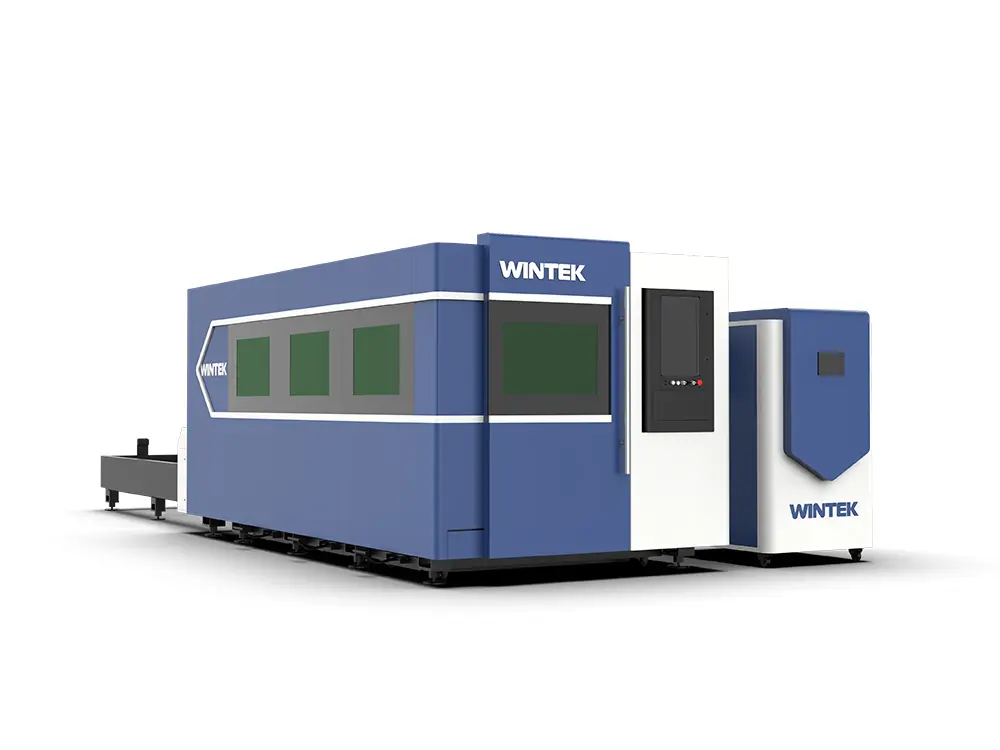

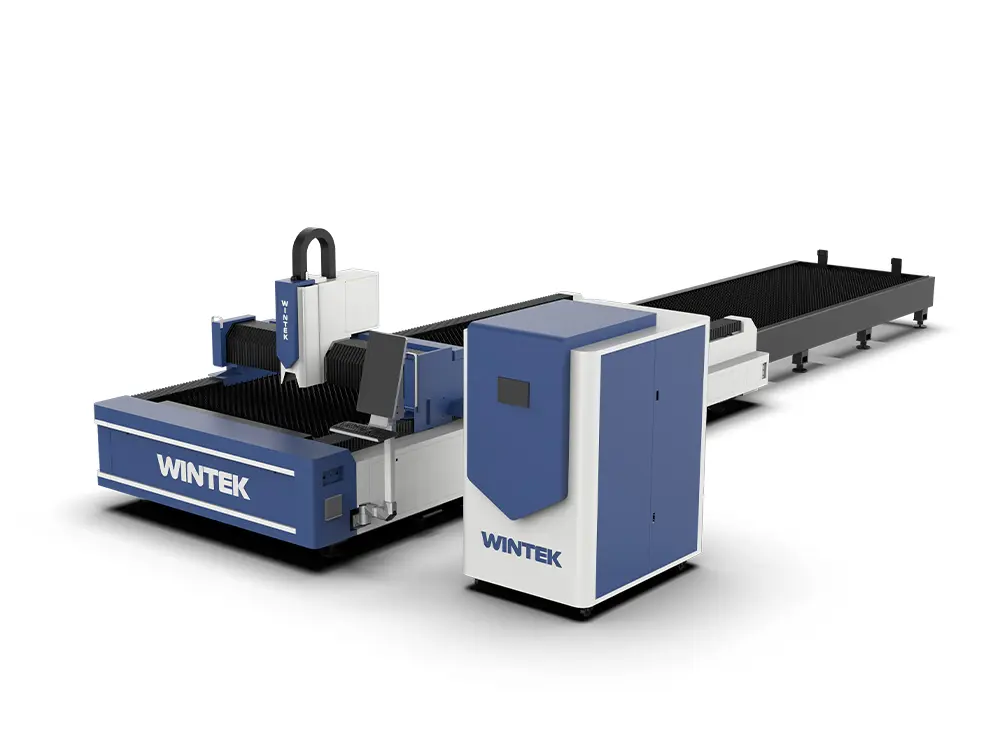

The double platform fiber laser cutting machine is an efficient design to improve cutting efficiency and ease of operation. The exchange table can achieve rapid loading and unloading during the cutting process without stopping the machine, greatly shortening the working cycle and improving production efficiency. Its sturdy structure, smooth operation, and strong load-bearing capacity can meet the cutting needs of materials of various sizes and weights.

WINTEK exchange table design allows the machine to work continuously during cutting. The exchange table system allows the workbench to be accurately aligned when replaced, ensuring that the cutting accuracy is not affected. Support processing of different sizes and materials to meet diverse production needs.

▍Fiber Laser Metal Cutting Machine 1KW-30KW Technical Parameters

| WTE Series Dual Table Fiber Laser Cutting Machine | |||||

|---|---|---|---|---|---|

| Model | WT3015E | WT4020E | WT6015E | WT6020E | WT6025E |

| Working Area | 3000*1500 | 4000*2000 | 6000*1500 | 6000*2000 | 6000*2500 |

| Worktable Bearing Capacity | 1250kg | 1650kg | 2500kg | 2500kg | 3500kg |

| Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Repeat Positioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Acceleration | 1G-2.5G | 1G-2.5G | 1G-2.5G | 1G-2.5G | 1G-2.5G |

| Running Speed | 80-140m/min | 80-140m/min | 80-140m/min | 80-140m/min | 80-140m/min |

| Machine Bed | Plate welding bed | Plate welding bed | Plate welding bed | Plate welding bed | Plate welding bed |

| Dimensions | 8300*2220*2300 | 10500*2900*2300 | 14800*2220*2300 | 14800*2900*2300 | 14800*3600*2300 |

| Laser Power | 1000W-30000W | ||||

| Cutting Thickness | 1–50mm (Depends on Material and Power) | ||||

| Optional Features | Voltage Regulator, Dust Collector, Air Compressor | ||||

▍Fiber Laser Metal Cutting Machine Sample

▍Fiber Laser Metal Cutting Machine Configuration

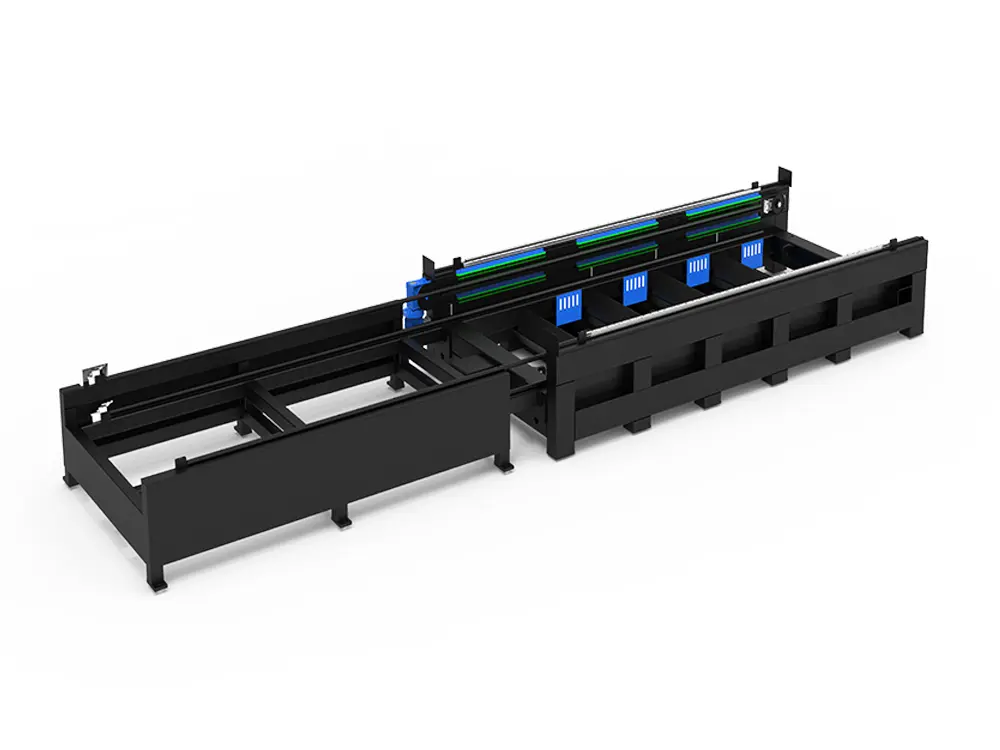

Pneumatic Exchange Platform

The fiber laser cutting machine is equipped with two worktables, one for cutting and the other for loading and unloading. The platforms can be switched automatically to reduce the idle time of the equipment.

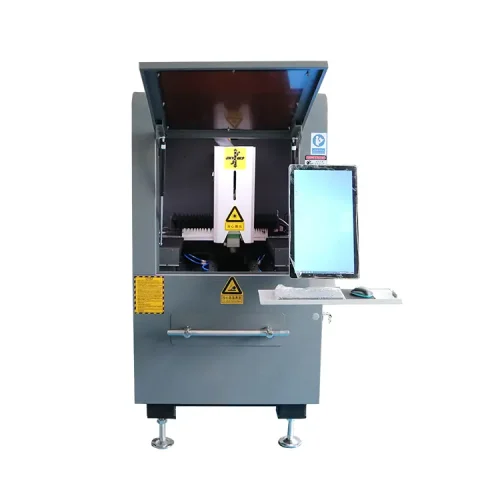

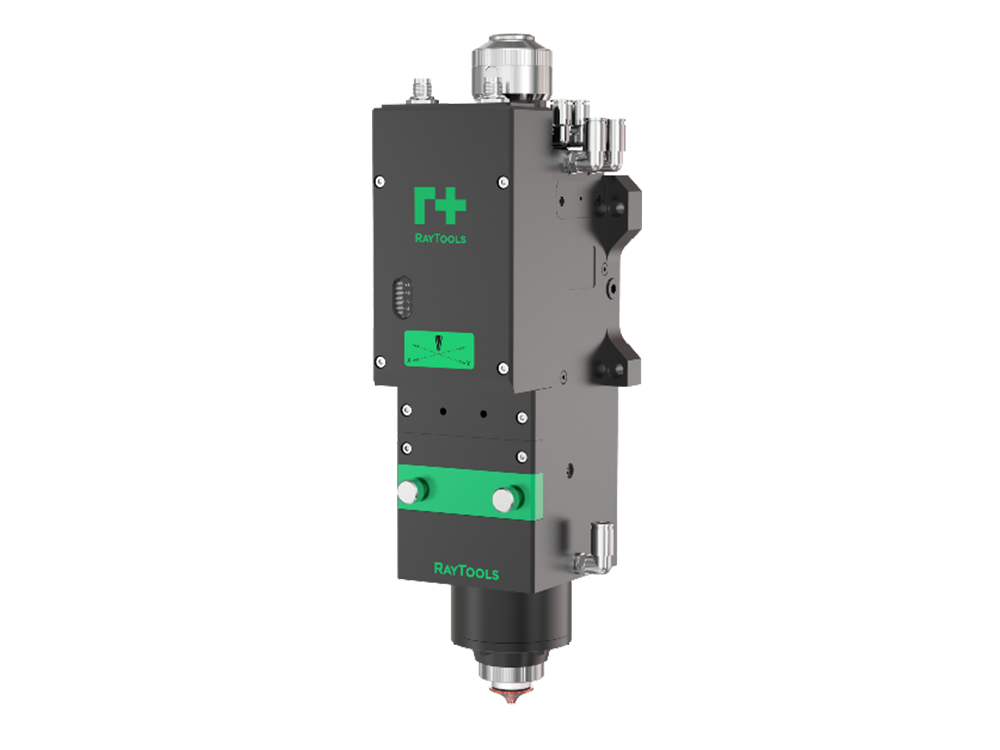

Flexible and Durable Cutting Head

Completely sealed internal structure can avoid optical parts polluted by dust. Collimator lens and focus lens are equipped in drawer installation way, which is convenient for maintenance and replacement. Adopting water-cooling heat sink inside to reduce the temperature of the cutting head to improve its service life.

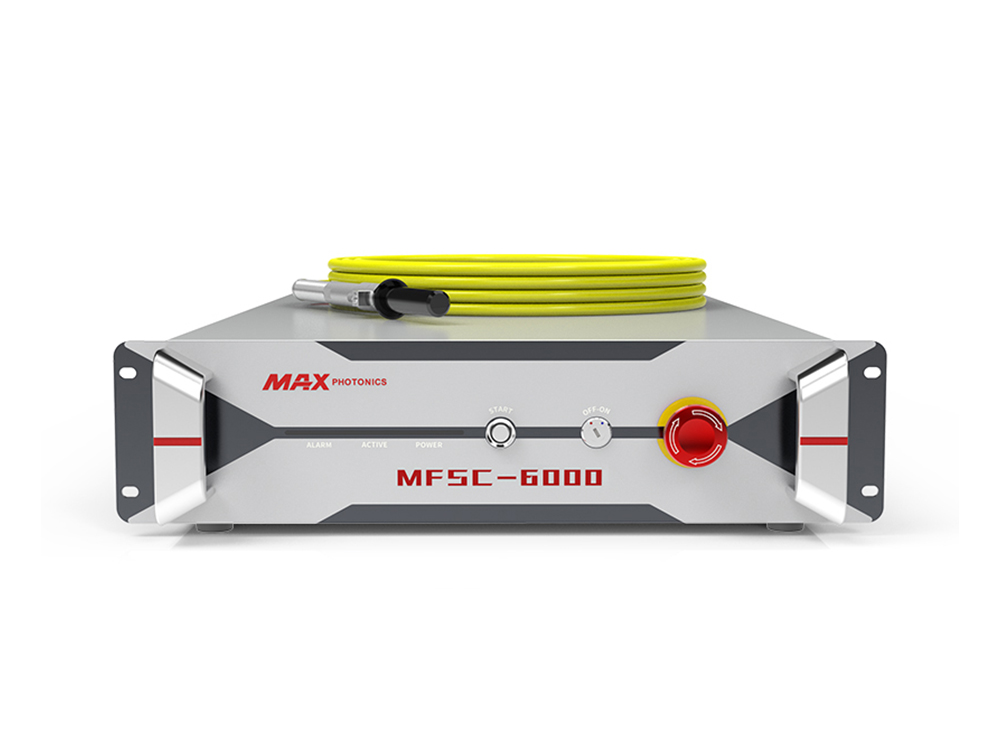

Fiber Laser Source

Fiber laser cutting machine system uses high-efficiency lasers with high conversion efficiency and can provide powerful laser output. The fiber lasers provide stable power output, avoiding the influence of power fluctuations on cutting quality and cutting speed.

Taiwan Hiwin Rails & YYC Gears

– Smooth transmission.

– Quiet, non-polluting, reliable and long-lasting.

– Achieve high precision and speed in cutting process.

– Excellent quality and stability, in accordance with international standards.

Fiber Laser Cutting Machine - Other Core Components

Water Chiller

Aviation Aluminum Beam

Intelligent Operating System

Japan Servo Motor and Driver

▍Fiber Optic Laser Cutter Benefits

With the dual exchange platform structure, the exchange time can be completed within 10-15 seconds. Cutting and loading can be performed at the same time, which greatly reduces the exchange time and improves production efficiency.

The gear rack transmission system has good rigidity and higher precision, which saves the waiting time for loading and unloading. Compared with the traditional sprocket chain transmission method, its performance in all aspects has been significantly improved.

Stable performance, high cutting quality, full positioning of the guide rail, and high-quality finishing technology bring stable processing accuracy, efficient cutting ability, and accurate positioning effect.

Professionally used for cutting a variety of metal plates, high-quality cutting of carbon steel plates, stainless steel plates, aluminum alloy plates, galvanized plates, silicon steel, titanium alloys, aluminum-zinc plates and other materials.

Fiber Laser Metal Cutting Machine Upgrade Series

AT – series

This fiber laser cutting machine can cut sheets and tubes, combining two functions in one to save costs. It can cut plates up to 35mm thick and pipes up to 6m/350mm.

DETAILS

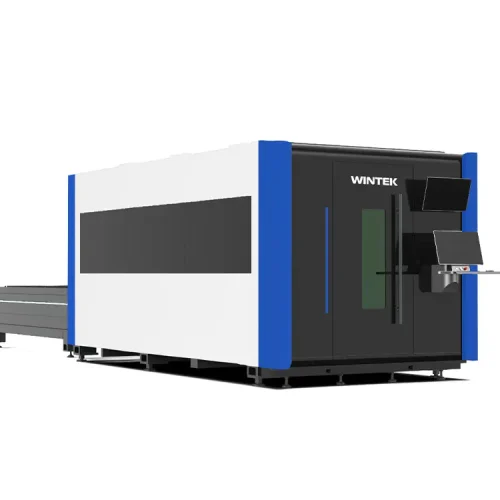

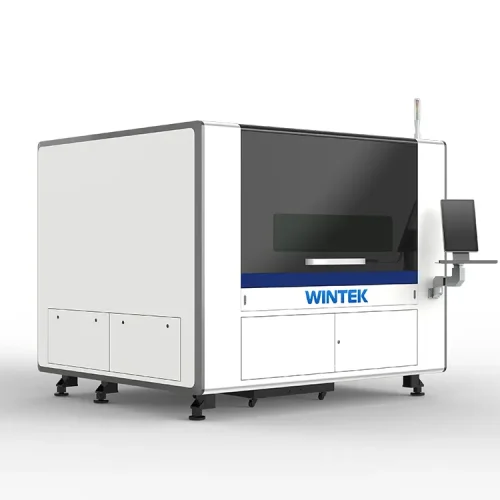

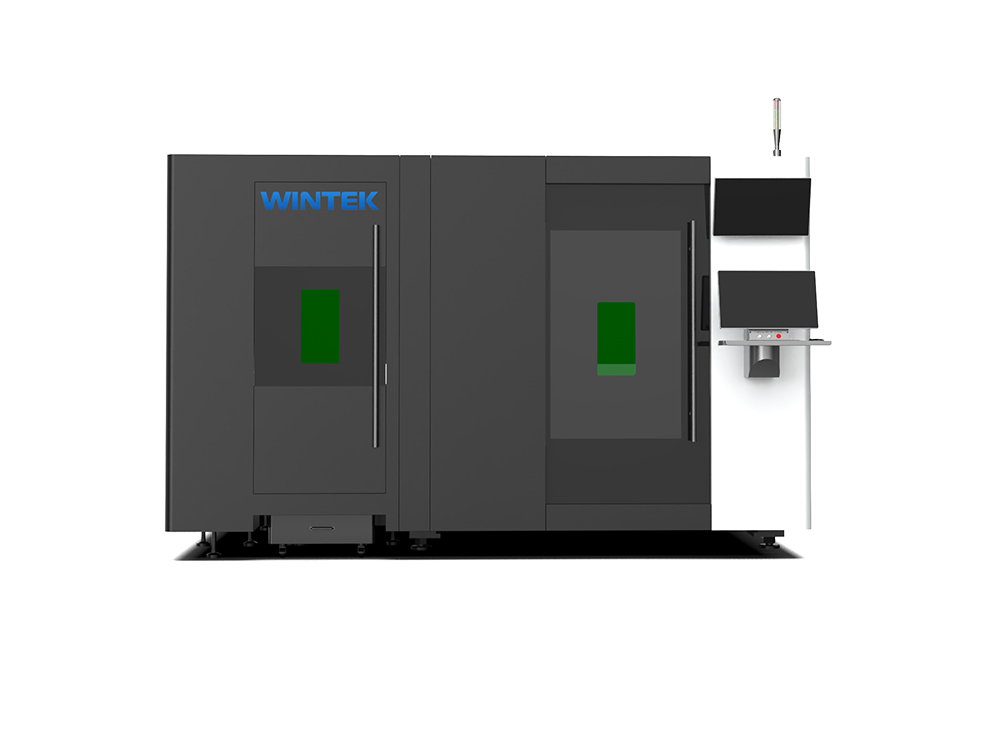

P – series

The fully enclosed fiber laser cutting machine ensures maximum safety, reduced noise, and improved efficiency, making it ideal for high-precision industrial applications.

DETAILS

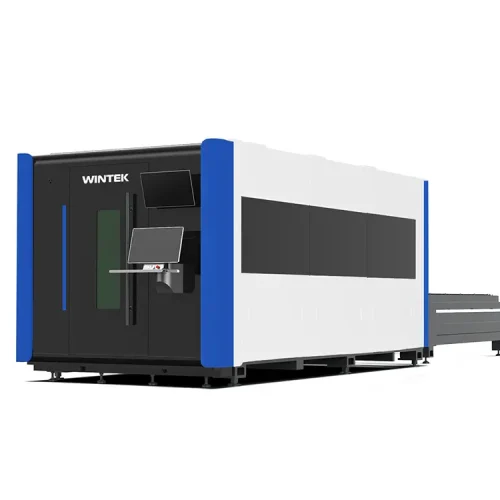

ATP – series

Equipped with a fully enclosed design, exchange table, and pipe-cutting capabilities, this machine ensures safety, efficiency, and versatility for sheet and tube processing.

DETAILS▍Fiber Laser Metal Cutting Machine FAQs

Q: How long can a fiber laser metal cutting machine be used? How long is your warranty?

Wintek laser cutting machines are a long-term investment, designed for a lifespan of over ten years, as the fiber laser source typically has a rated service life exceeding 100,000 hours. Our standard warranty includes 2 years for the entire machine and consumable parts. During the warranty period, we provide free technical support and replacement for non-consumable components that fail due to manufacturing defects.

Q: What are the wearing parts of a fiber laser metal cutting machine?

In the field of laser cutting, certain components require special attention to maintain optimal performance. These include protective lenses, nozzles, and ceramic rings. Proper maintenance and timely replacement of these parts are essential to ensure the machine operates at its best.

Q: What auxiliary gases are required when using a fiber laser metal cutting machine?

Fiber laser metal cutting machines require auxiliary gases such as oxygen, nitrogen, or compressed air to enhance cutting performance. Oxygen is commonly used for cutting carbon steel, improving efficiency and creating smooth cuts, though it may cause slight oxidation on the edges. Nitrogen is preferred for stainless steel and aluminum, as it prevents oxidation and ensures polished, clean edges. Compressed air is a more cost-effective option, suitable for basic cutting tasks and thinner materials. The choice of gas depends on the material, thickness, and desired edge quality, with proper pressure and flow being crucial for achieving the best results.

Q: What are the main advantages of a fiber laser metal cutting machine?

Fiber laser metal cutting machines excel in high precision, fast speeds, and versatility, processing materials like carbon steel, stainless steel, and aluminum. They are energy-efficient, cost-effective, and low-maintenance, with a long lifespan and consistent performance, making them ideal for industries requiring accuracy and efficiency.

Contact us now to explore our metal laser cutters. Fill out the form for a personalized quote. Our team is ready to provide you with tailored solutions and support.