Fiber Laser Cutting Video On Youtube

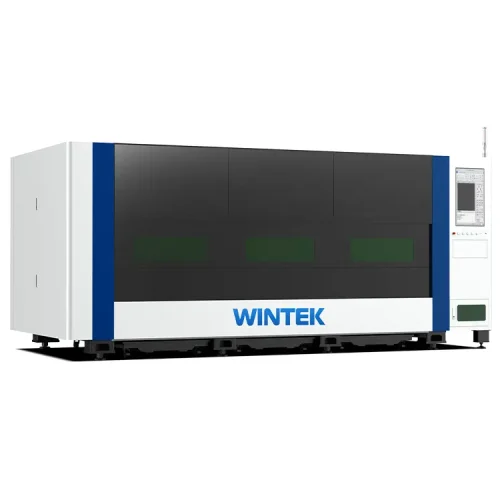

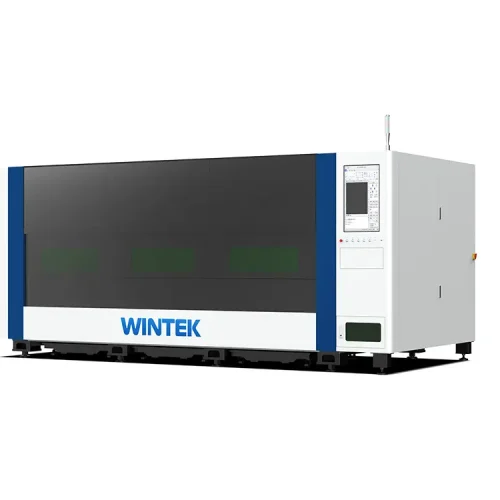

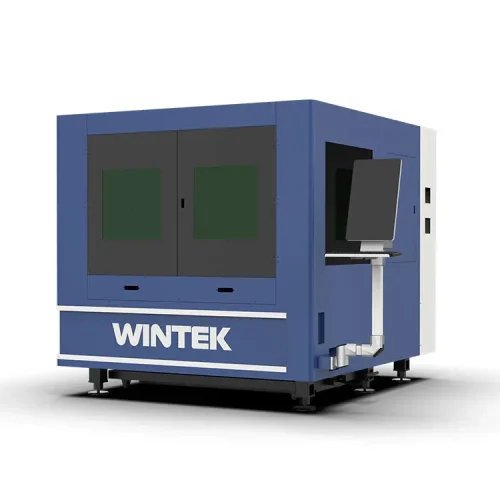

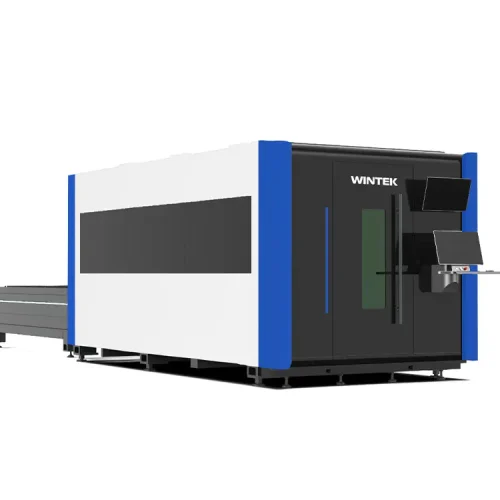

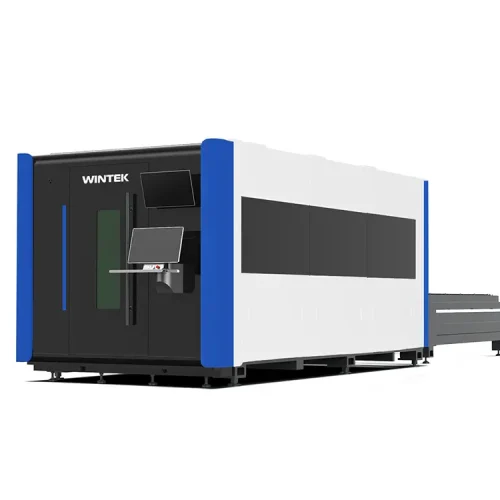

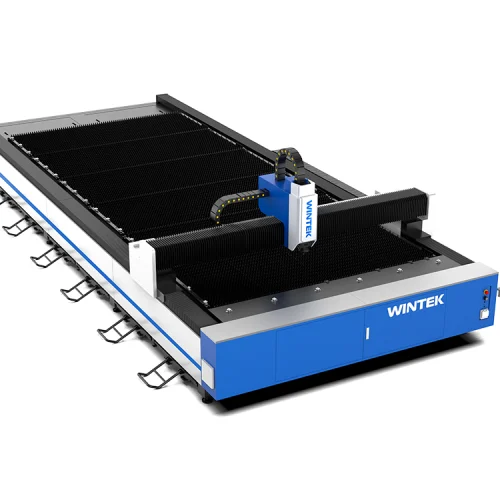

▍Flatbed Laser Cutting Machine Description

The 1325 flatbed laser cutting machine is designed to meet the demands of modern industries, offering a power range from 1KW to 12KW for precise cutting of various metal materials. It is an ideal solution for applications in automotive manufacturing, construction, home appliances, aerospace, and other industries.

This machine features a fully enclosed design, significantly enhancing operational safety by preventing laser radiation and minimizing the spread of dust and fumes. Its sturdy flatbed structure, combined with a high-precision transmission system, ensures stability and accuracy during high-speed cutting, effortlessly handling complex processing requirements.

Advanced fiber laser technology is a key highlight of this machine. It delivers fast cutting speeds and high efficiency, producing smooth, burr-free edges that reduce post-processing costs and time. Additionally, the machine is equipped with an intelligent operating system featuring a user-friendly interface, allowing for easy parameter adjustments and seamless switching between various cutting modes to accommodate different materials and applications.

Wintek 1325 laser cutting machine uses core components from globally renowned brands, ensuring long-term stable performance through rigorous testing and quality assurance. Its low maintenance costs and extended lifespan make it a valuable investment for any business.

▍Flatbed Laser Cutting Machine 1KW-12KW Technical Parameters

| Product Name | WT1325P |

| Laser Power | 1000W-12000W |

| Cutting Area | 1300mm × 2500mm (optional customization for larger sizes) |

| Laser Wave Length | 1064nm |

| Position Accuracy | ±0.03mm |

| Repeatability Accuracy | ±0.02mm |

| Max Acceleration | 0.8G-1.5G |

| Cutting Speed | 80-140 m/min |

| Table Load Bearing | 700kg |

| Dimensions | 4450mm × 2100mm × 2130mm |

| Overall Weight | 4060kg |

▍Flatbed Laser Cutting Machine Sample

▍Flatbed Laser Cutting Machine Configuration

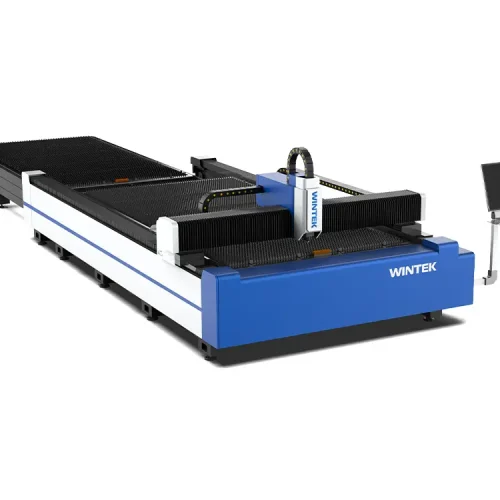

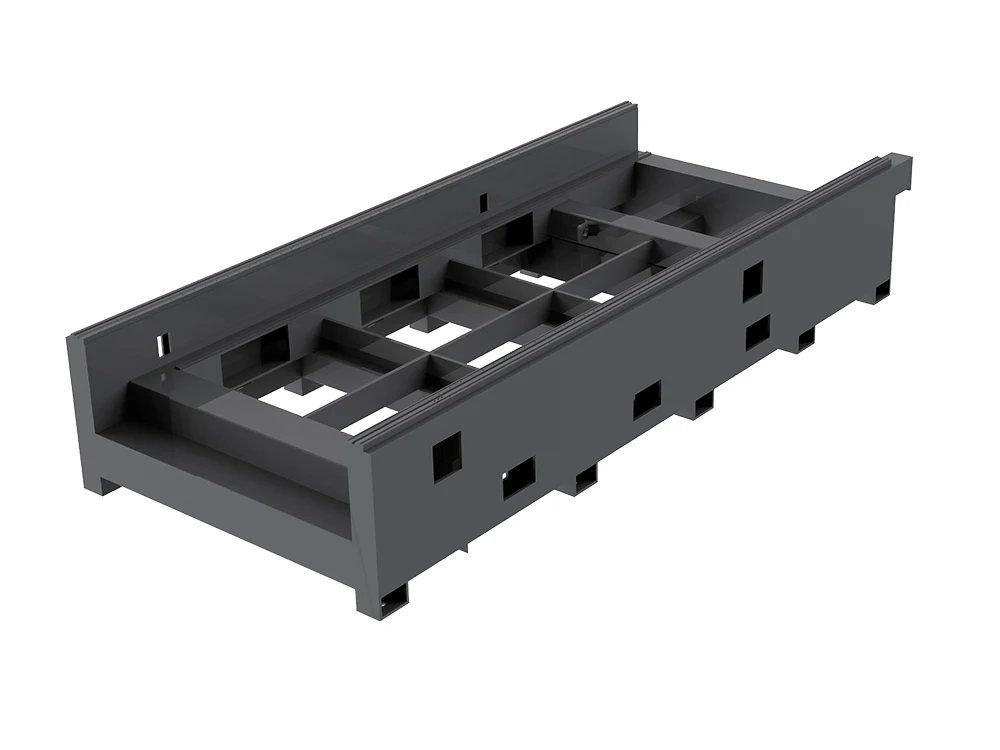

Laser Machine Bed

The machine bed features a heavy-duty welded steel structure, treated with high-temperature annealing and vibration aging to maintain stability and prevent deformation over prolonged use. Its robust design provides excellent support and stability during high-speed cutting, meeting the demands of high-precision processing.

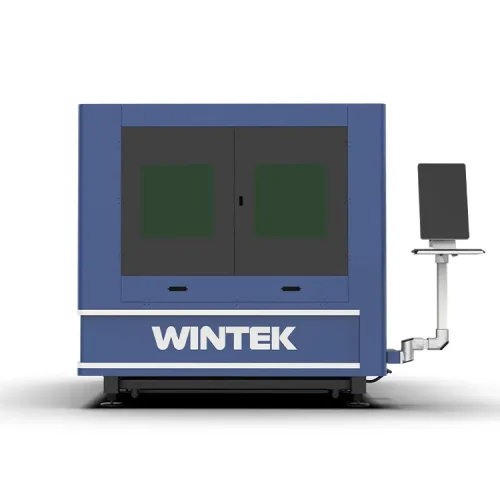

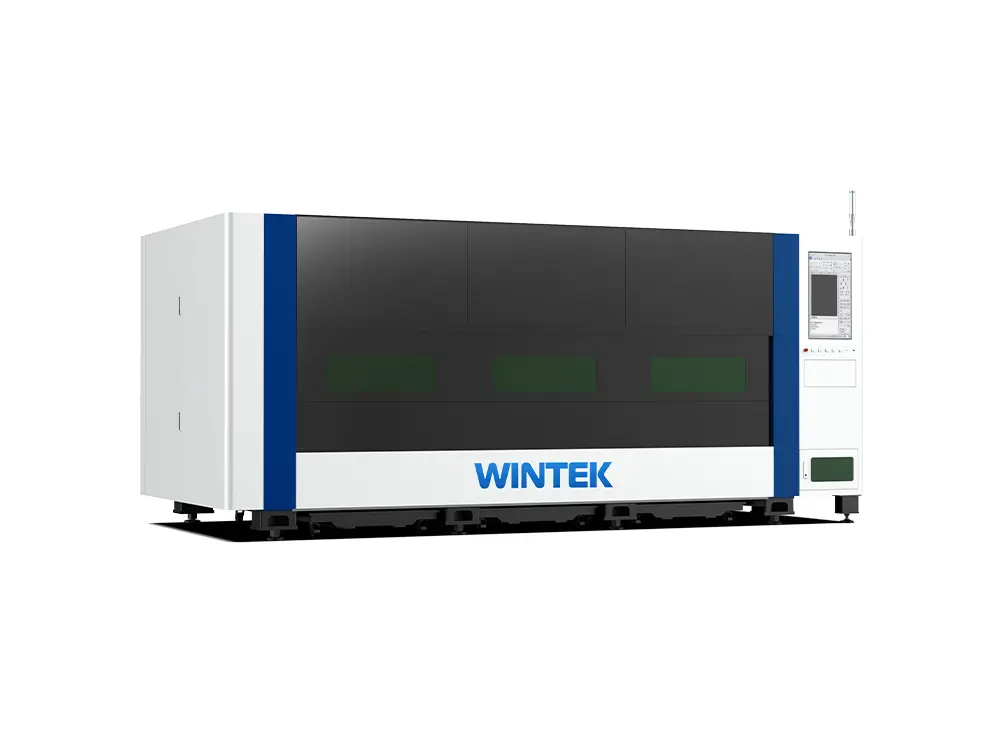

Highly Integrated Design

One-key electric interactive door opening.

Combined with a pull-up and pull-down material structure.

High equipment space utilization.

More secure and efficient production.

MAX Fiber Laser Source

Equipped with MAX fiber laser, the machine offers power options ranging from 1000W to 12000W, capable of cutting various materials. The MAX laser is renowned for its high electro-optical conversion efficiency, stable performance, and over 100,000 hours of operational lifespan. Its exceptional beam quality ensures smooth, burr-free cutting edges, making it ideal for precision applications.

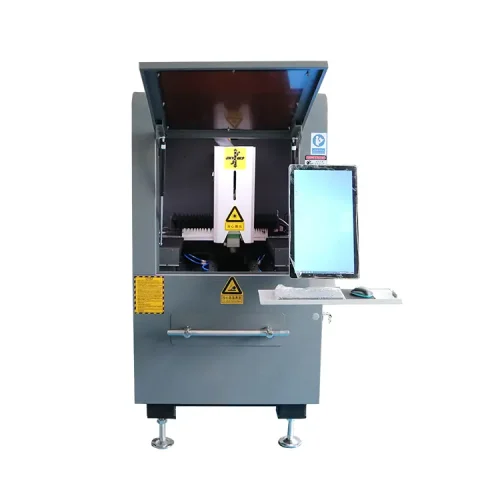

Laser Cutting Head

The cutting head features an advanced autofocus system that automatically adjusts the focal point based on material thickness. This ensures high precision and efficiency during the cutting process. The cutting head is equipped with anti-collision functionality and an efficient cooling system, enhancing its stability and lifespan.

Fiber Laser Cutting Machine - Other Core Components

Intelligent Operating System

Water Chiller

Taiwan Hiwin Rails & YYC Gears

Japan Servo Motor and Driver

▍Flatbed Laser Cutting Machine Benefits

- High Precision: Combined with advanced fiber laser technology, ensures precise cuts with smooth, burr-free edges, suitable for intricate designs and high-quality finishes.

- Enhanced Stability: The heavy-duty, welded steel machine bed provides robust support, ensuring stability and minimal vibration during high-speed operations.

- Improved Efficiency: High cutting speeds, coupled with automated features such as autofocus and intelligent software, reduce setup time and increase productivity.

- Cost-Effective Operation: The fiber laser’s high electro-optical conversion efficiency results in lower energy consumption and reduced operating costs.

- Safety and Clean Environment: Fully enclosed designs prevent laser radiation and minimize dust and fume emissions, creating a safer and more eco-friendly workspace.

- Long Equipment Lifespan: Premium components from global brands and features like efficient cooling systems ensure long-term stability and reduce maintenance needs.

- User-Friendly Interface: Equipped with advanced CNC control systems and intuitive software, the machine offers ease of operation and supports various file formats.

- Scalability: Customizable cutting areas and power options cater to specific business needs, from small-scale operations to large industrial production lines.

- Time-Saving Features: Automatic height adjustment, fast material loading, and the ability to cut various materials without tool changes streamline the production process.

Contact us now to explore our fiber laser cutters. Fill out the form for a personalized quote. Our team is ready to provide you with tailored solutions and support.