Fiber Laser Cutting Video On Youtube

Metal Laser Cutting Machine Description

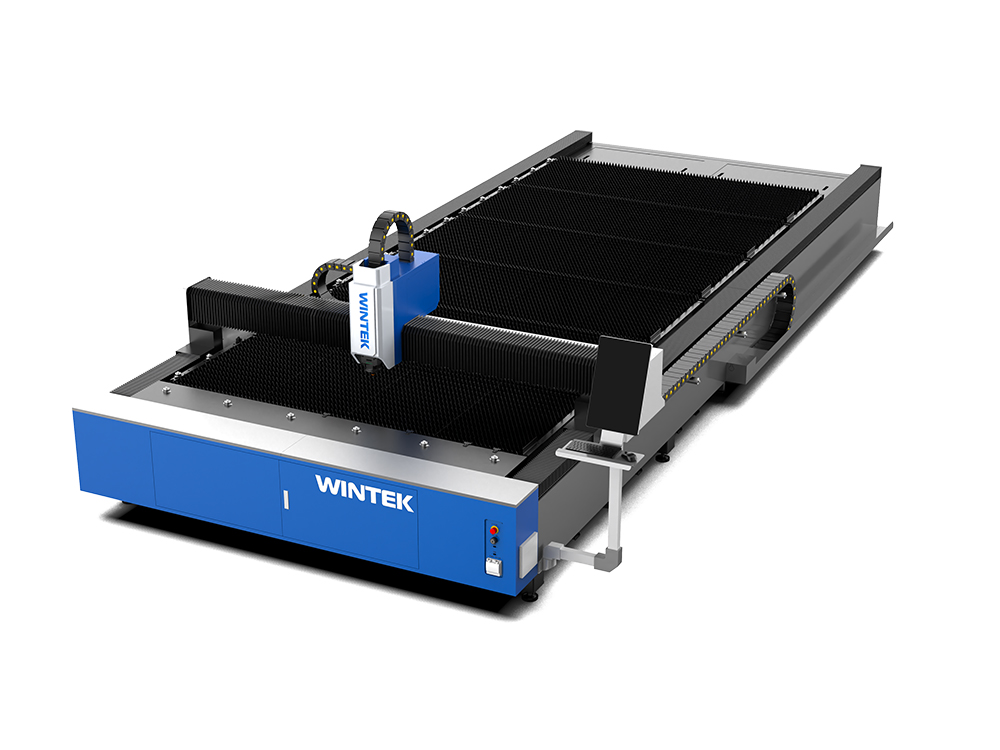

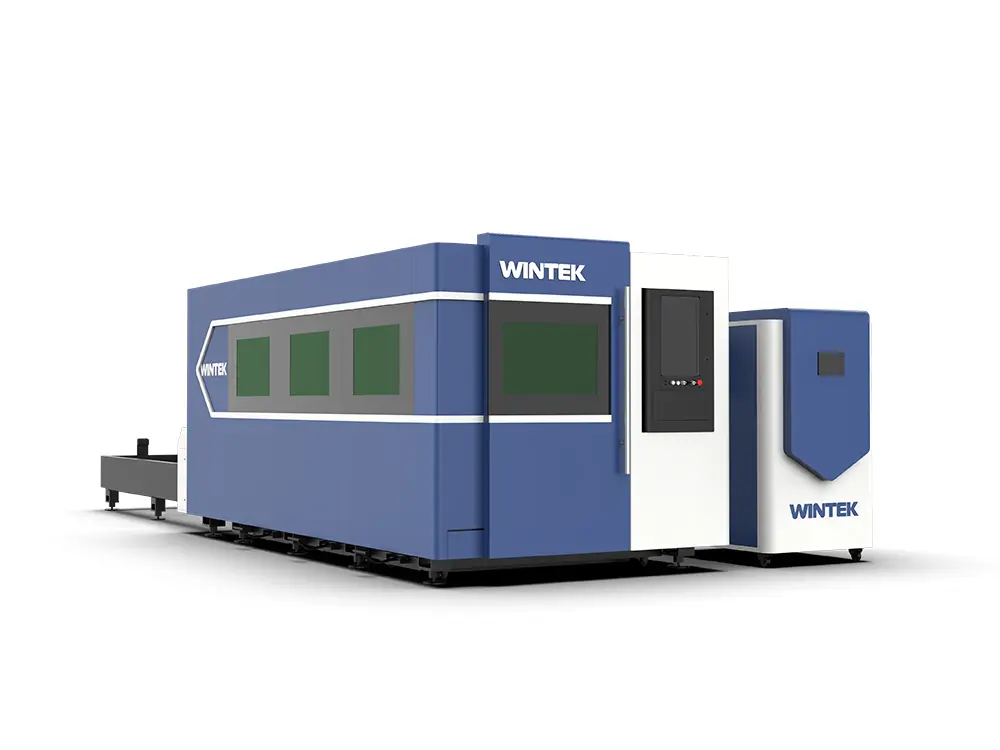

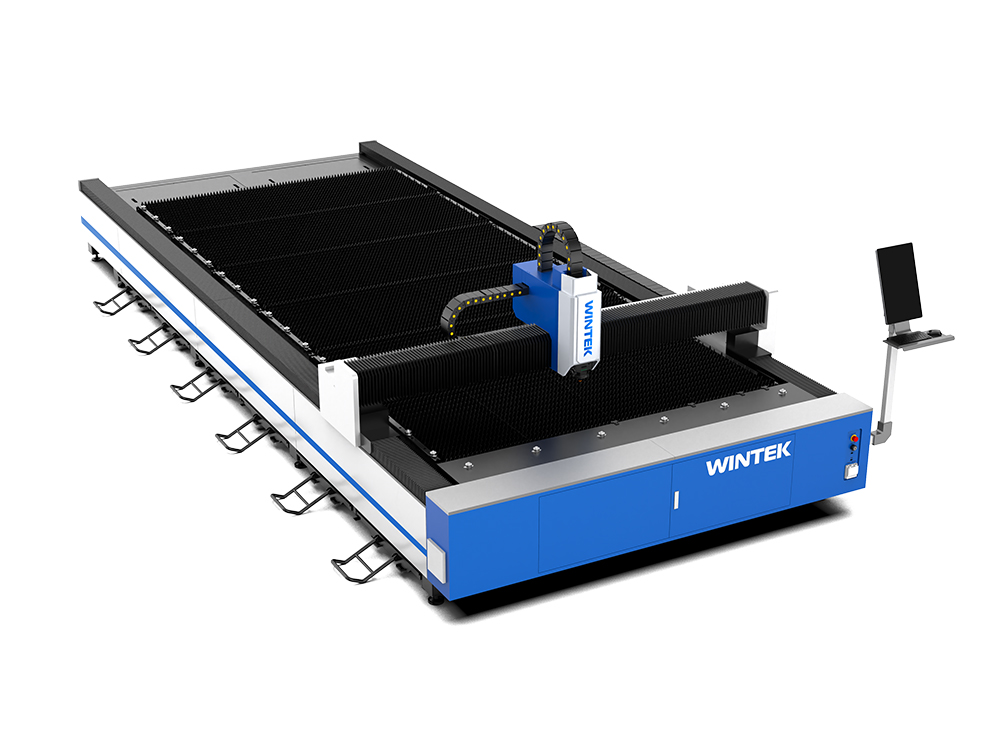

Wintek laser metal cutting machine is equipped with a 6000mm×2000mm extra-large worktable, which is suitable for the processing needs of large-size metal plates. It does not require segmented cutting, improves production efficiency, and meets the overall forming needs of complex workpieces. It can cut a variety of metal materials, including carbon steel, stainless steel, aluminum, copper, brass, titanium alloy, iron, etc.

The metal laser cutting machine adopts an integral welded bed and a high-strength gantry structure to ensure mechanical stability and durability during long-term work. Using high-power fiber lasers, the cutting accuracy is as high as ±0.03mm, the edges are smooth and burr-free, and high-precision processing of complex graphics can be easily achieved.

UPGRADE SERIES

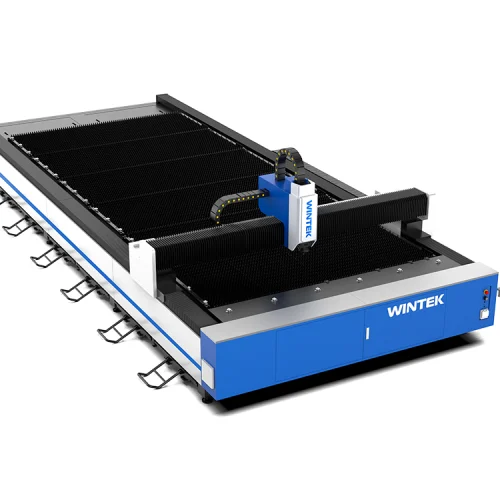

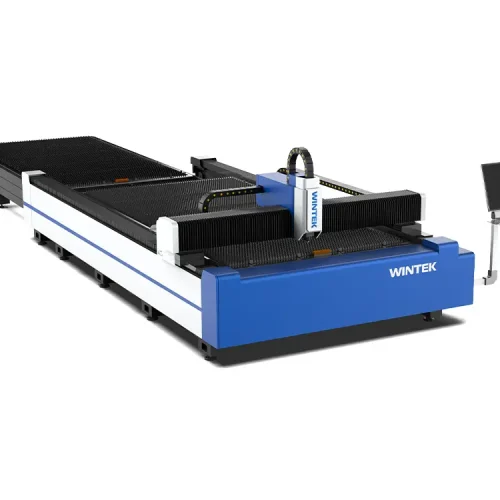

AE – series

The fiber laser cutting machine features a 10-15s exchange platform, enabling rapid material changes to boost productivity and minimize downtime.

DETAILS

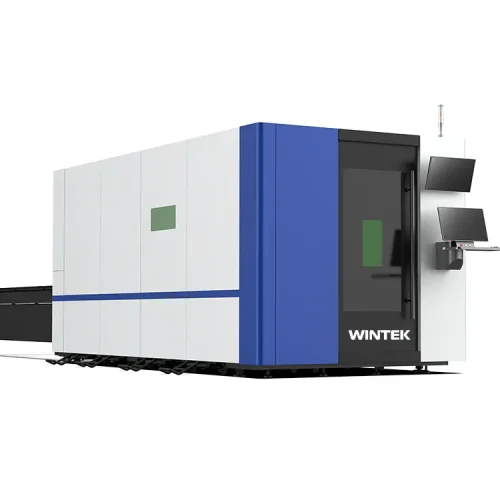

AT – series

This fiber laser cutting machine can cut sheets and tubes, combining two functions in one to save costs. It can cut plates up to 35mm thick and pipes up to 6m/350mm.

DETAILS

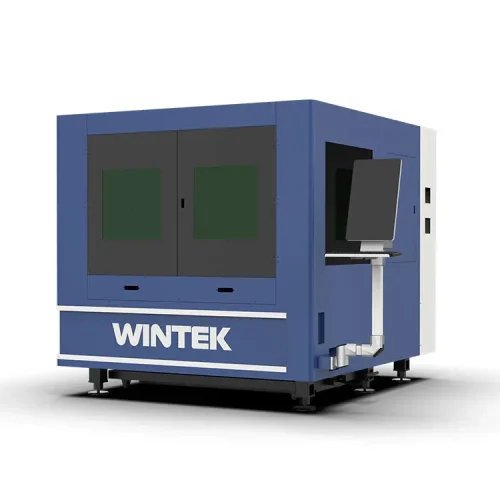

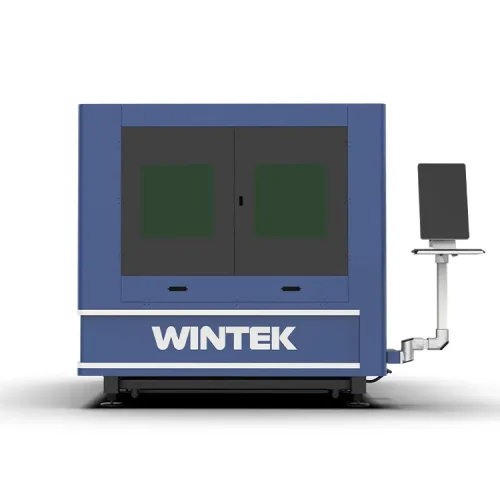

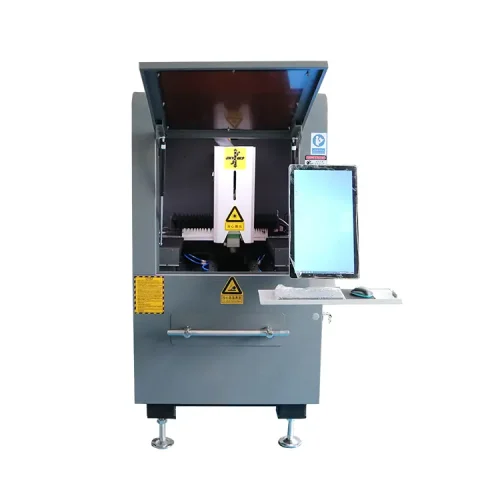

P – series

The fully enclosed fiber laser cutting machine ensures maximum safety, reduced noise, and improved efficiency, making it ideal for high-precision industrial applications.

DETAILSTechnical Parameters

Below is a summary of the key specifications for the metal laser cutting machine, highlighting its performance metrics. It is designed for precision and efficiency and is an ideal solution for various industrial cutting needs.

| Equipment model | WT6020A |

| Fiber Laser Power | 1KW-30KW |

| Cutting Area | 6050mm×2030mm |

| Moving Speed | 80-140 m/min |

| Position Accuracy | 0.02mm |

| Cutting Head | Automatic focus cutting head |

| Reducer | Japan Shimpo |

| Electrical Components | France Schneider |

| Machine Gantry | Aviation grade cast aluminum beam |

| Repeat Positioning Accuracy | ≤±0.02mm/m |

| Machine Structure | Big thickness stable & strong welding plate structure |

| Max Acceleration | 1G / 1.5G / 2.5G / 4G |

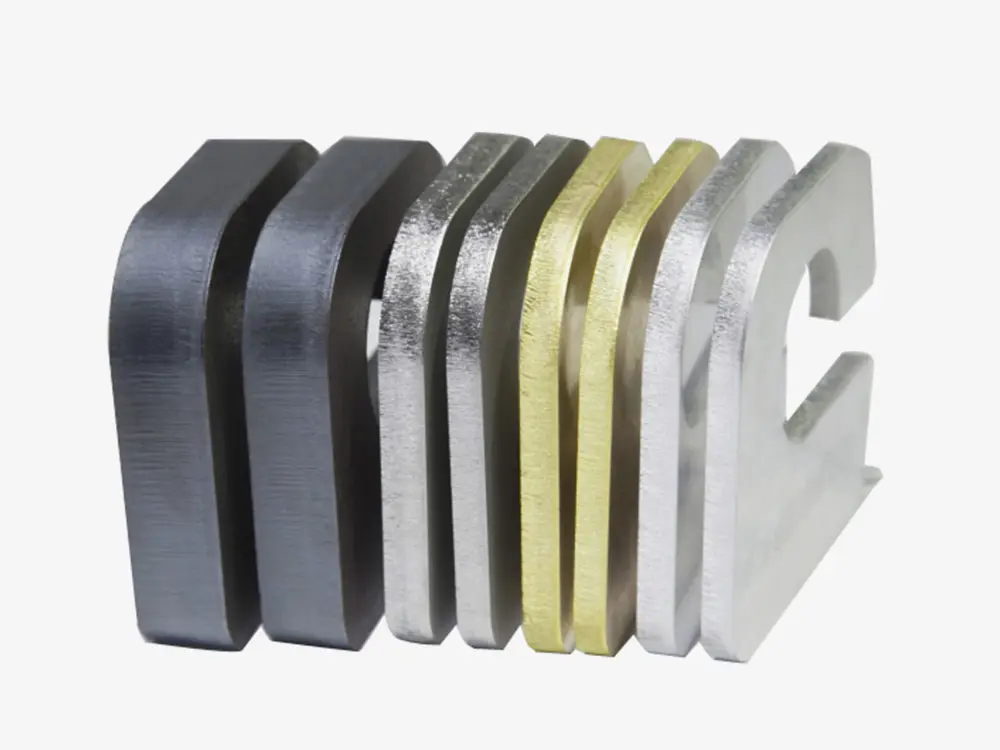

Fiber Laser Cutting Machine Sample

Machine Configuration

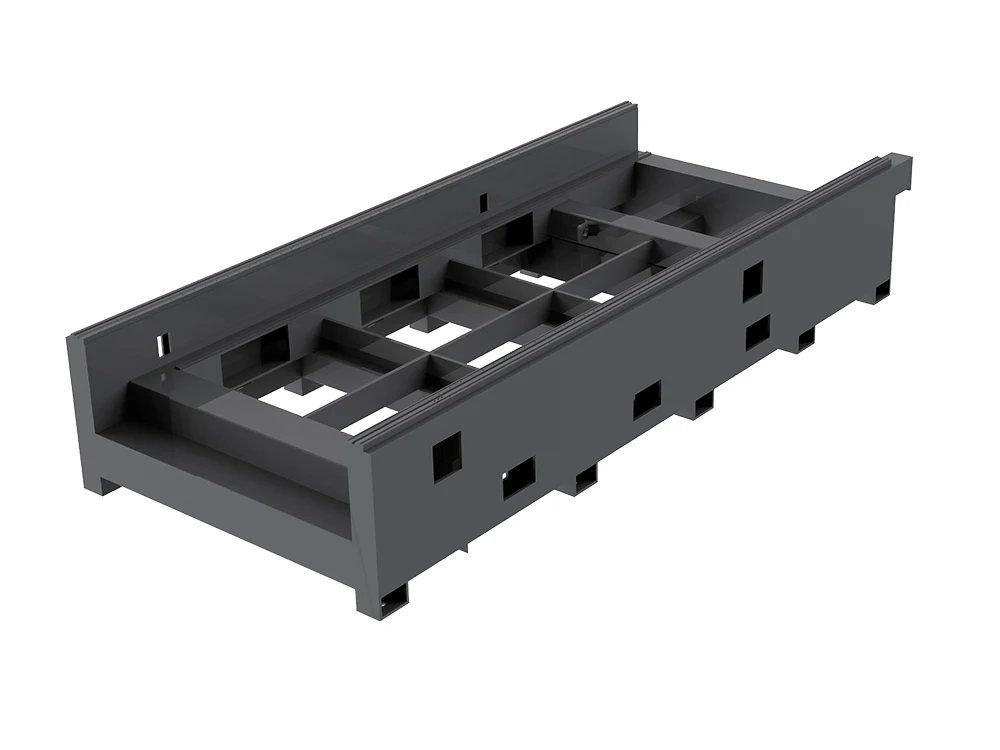

Heavy-Duty Steel Welded Bed

The whole bed adopts sheet metal welding design, which is treated by high temperature annealing and natural aging to eliminate welding stress and prevent bed deformation. After precise design and testing, the bed has high reliability and long-term trouble-free operation. Combined with advanced manufacturing techniques, it ensures exceptional performance and durability, making it an ideal choice for industrial applications.

Aviation Grade Tensile Aluminum Beam

The machine features an aerospace-grade stretched aluminum crossbeam, manufactured to aerospace standards and formed using a 4,300-ton press extrusion process. The crossbeam undergoes T6 heat treatment, ensuring maximum strength and exceptional resistance to deformation. It can withstand various loads generated during laser cutting and avoid loss of accuracy due to deformation.

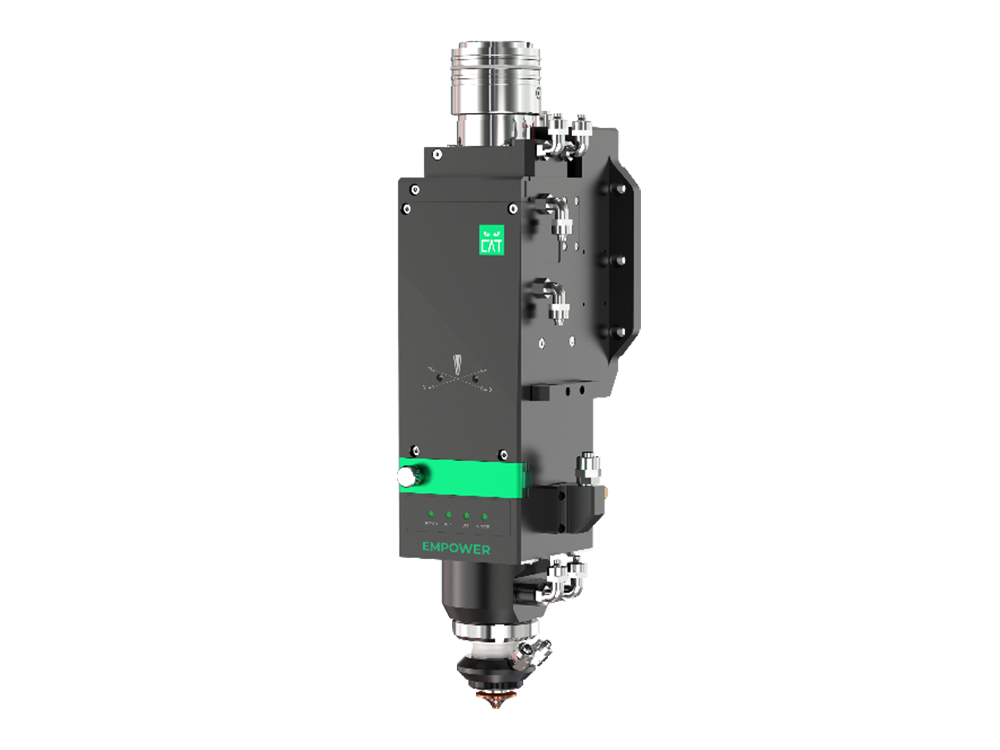

Laser Cutting Head

The laser head can focus the laser beam precisely on the surface of the material. It ensures that the laser beam maintains high quality and uniform energy distribution during transmission and focusing. It makes the cutting surface smooth and vertical, reducing defects. This advanced focusing capability also allows for efficient cutting of various materials and thicknesses, enhancing productivity.

Intelligent Operation Software

The cutting software offers advanced cutting path optimization, improving efficiency and reducing material waste. During the cutting process, the system can monitor the cutting situation of the material in real time and automatically adjust the cutting parameters (such as speed, power) to ensure the cutting effect.

Fiber Laser Cutting Machine - Other Core Components

Fiber Laser Source

Taiwan Hiwin Rails & YYC Gears

Japan SHIMPO Reducer

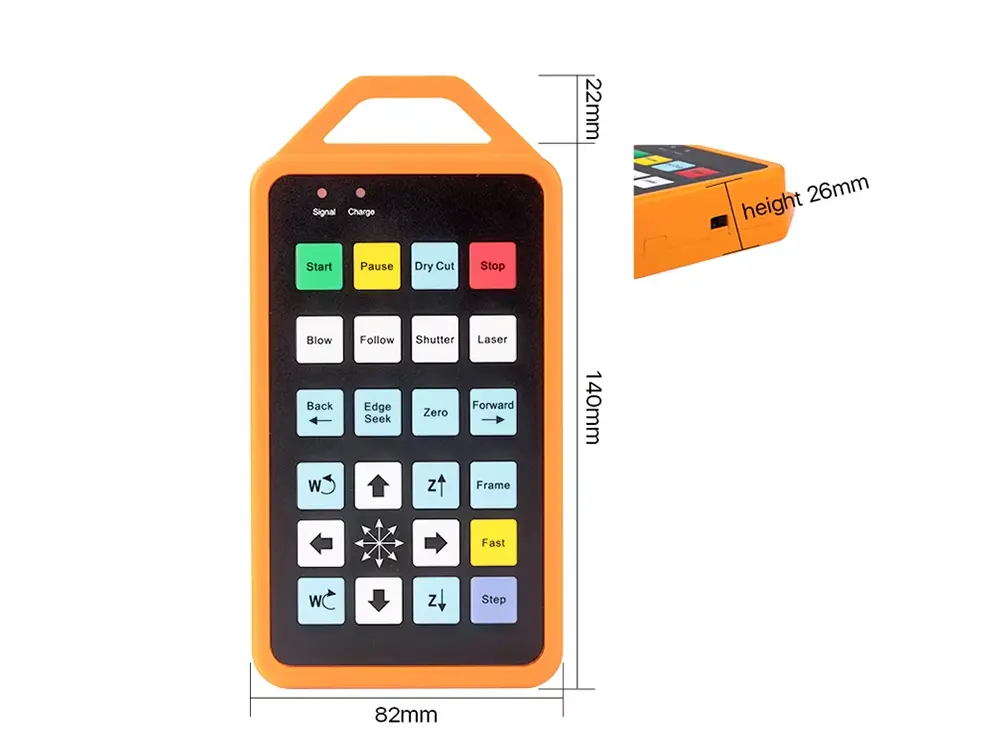

Wireless Handheld Control

Fiber Optic Laser Cutter Benefits

1. Low Cost of Use: Fiber laser cutting machines offer low operational and maintenance costs, ideal for businesses with multiple machines. Less maintenance means more cutting time, and their superior cutting efficiency reduces costs, benefiting small and medium-sized enterprises.

2. High Efficiency and Precision: Laser cutting machines lead the market in efficiency, offering higher photoelectric conversion, precise cuts, minimal energy waste, and better finishes. With stable power and proper settings, they eliminate the need for secondary processing, saving costs.

3. Convenient Operation: Modern fiber laser machines feature computer numerical control and remote operation. After importing cutting designs, they work automatically with minimal input. Many models also include automated loading and unloading, reducing labor costs further.

4. Wide Applications: Fiber laser machines are versatile, serving industries from heavy equipment, rail transportation, aerospace, to jewelry processing and advertising board processing. With power ranges from 1000W to 30000W, they can cut plates up to 80mm thick, making them adaptable for diverse needs.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.