Fiber Laser Cutting Video On Youtube

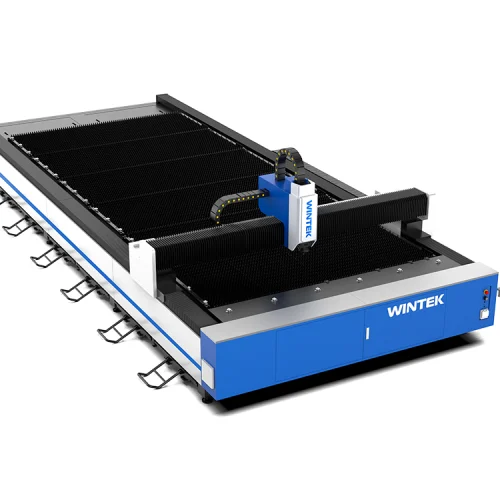

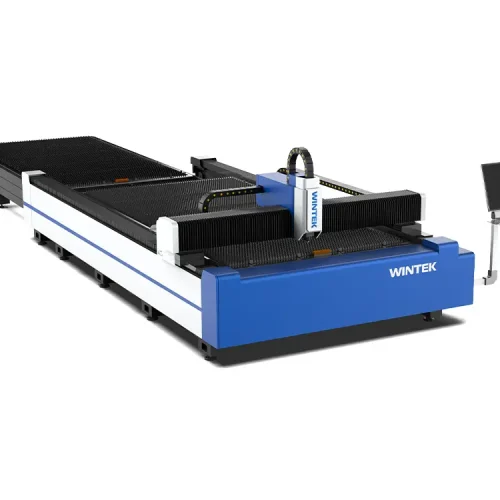

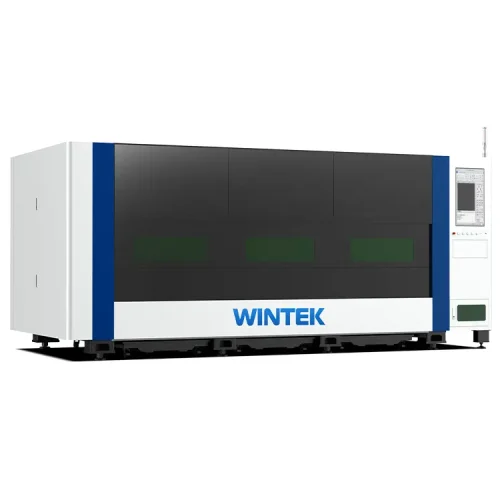

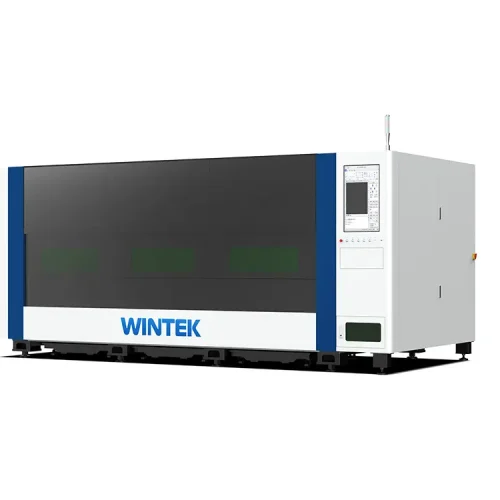

▍3030 Laser Cutting Machine Description

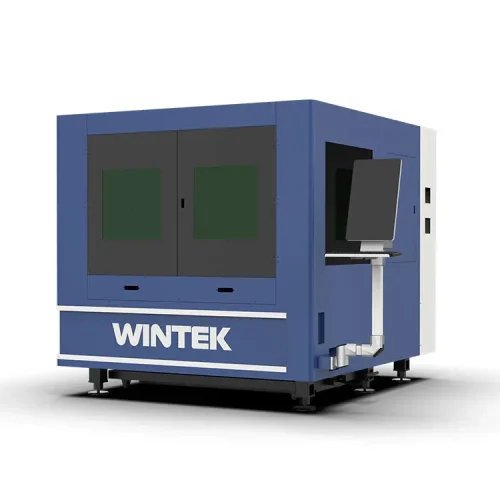

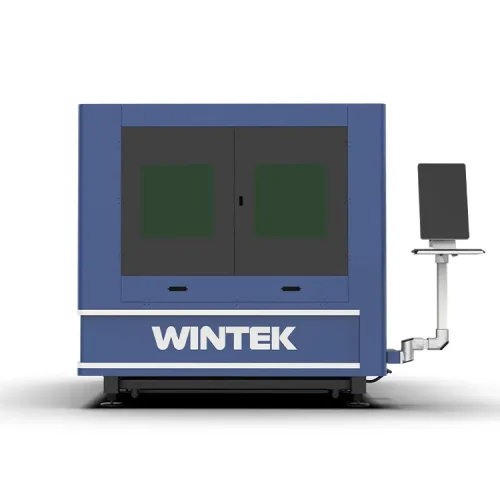

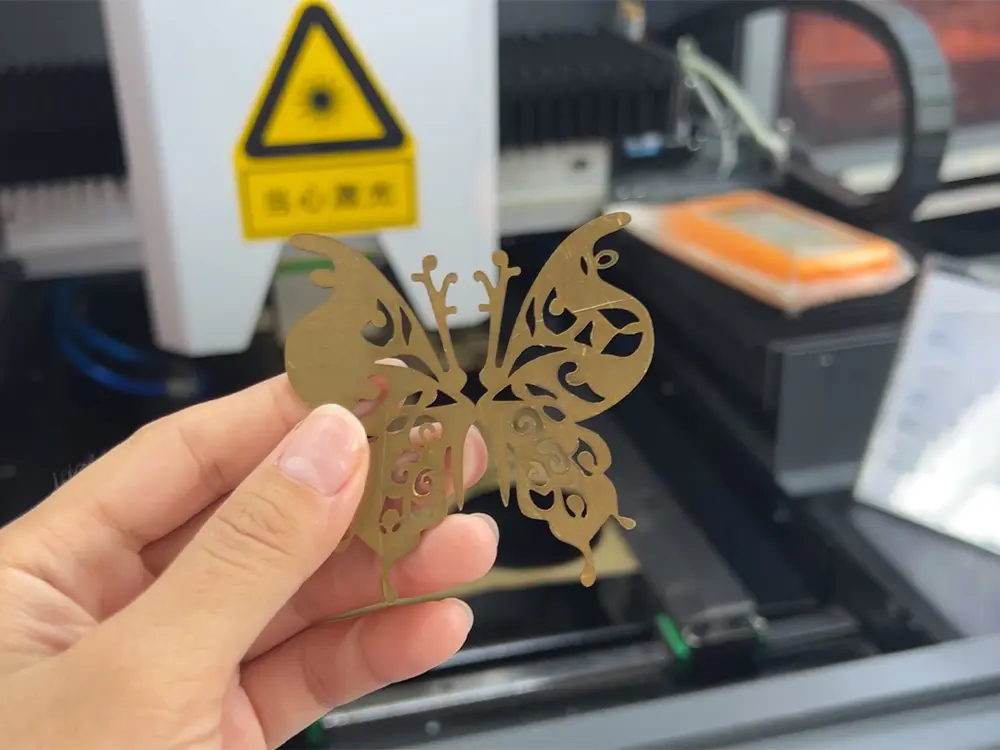

WT3030P sheet metal laser cutting machine uses advanced fiber lasers and precision transmission systems. The cutting accuracy can reach ±0.02mm, ensuring excellent processing quality and smooth edges without burrs. It is suitable for cutting various complex patterns and small workpieces.

Supports cutting of a variety of metal materials, including carbon steel, stainless steel, aluminum alloy, copper, titanium alloy, etc. It has a wide range of processing thickness and can meet the cutting needs of materials of different thickness.

Wintek sheet metal laser cutting machine is equipped with an advanced CNC control system, it supports intelligent typeset and one-button start, making it easy to operate. Real-time monitoring and diagnostics improve equipment reliability and reduce downtime.

▍3030 Laser Cutting Machine 1KW-3KW Technical Parameters

| Model | WT3030P | WT6060P | WT6090P | WT1390P |

| Working Area | 300*300mm | 600*600mm | 600*900mm | 1300*900mm |

| Worktable Bearing Capacity | 100kg | 200kg | 230kg | 250kg |

| Overall Weight | 0.6T | 0.8T | 1.0T | 1.3T |

| Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Repeat Positioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Acceleration | 0.8G-1.5G | 0.8G-1.5G | 0.8G-1.5G | 0.8G-1.5G |

| Laser Power | 1000W&1500W&2000W&3000W&6000W | |||

| Laser Generator | MAX / Raycus / IPG / Reci, etc | |||

| Machine Bed | Stable welding bed | Stable welding bed | Stable welding bed | Stable welding bed |

| Running Speed | 80-140m/min | 80-140m/min | 80-140m/min | 80-140m/min |

| Application Industry | Jewelry making, precision components, decoration, sheet metal fabrication, molds, hardware, etc. | |||

▍3030 Laser Cutting Machine Sample

▍3030 Laser Cutting Machine Configuration

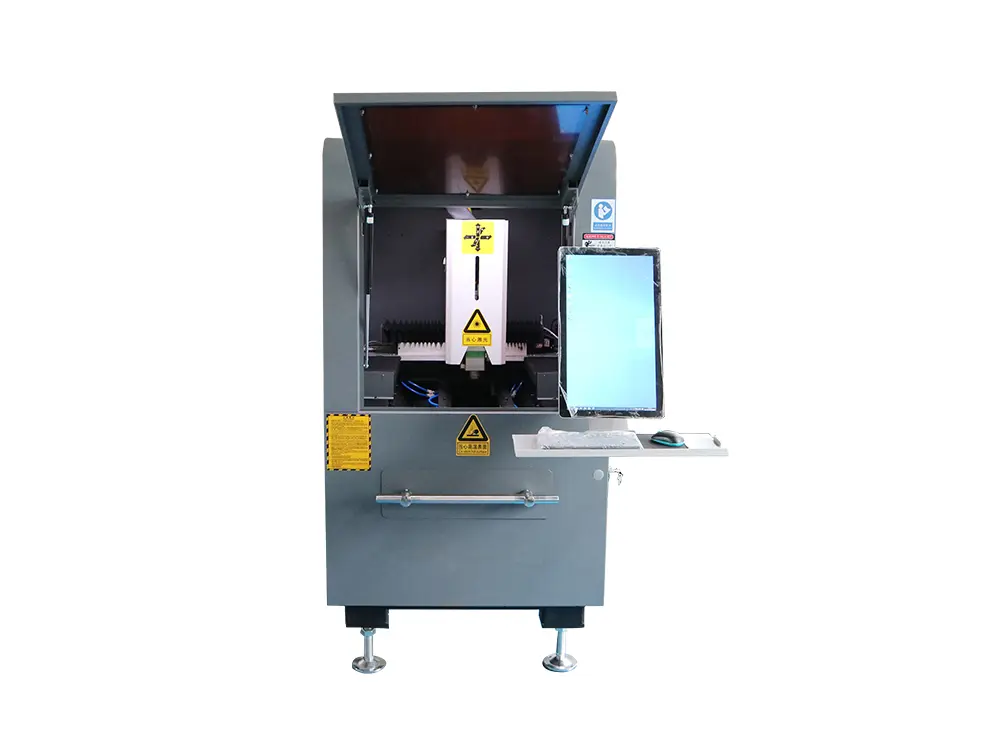

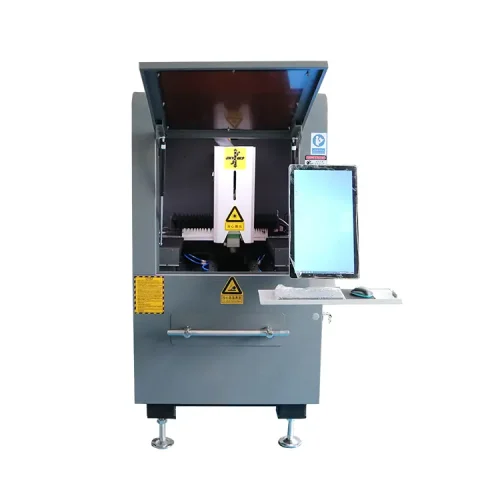

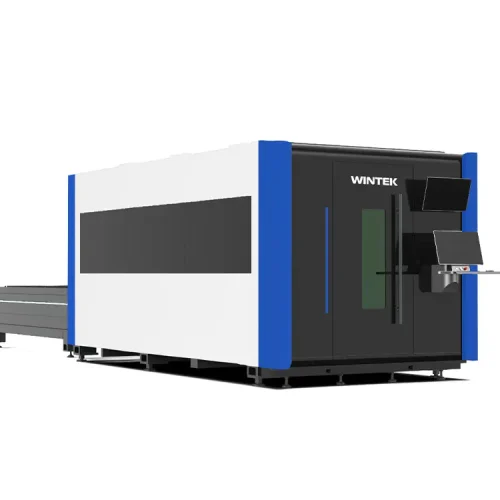

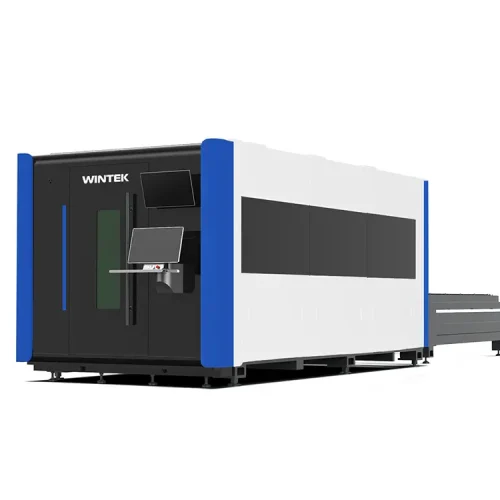

Mini Enclosed Protective Cover

The compact design is tailor-made for small fiber laser cutting machines, the cover is space-saving and easy to integrate into various working setups. The cover minimizes external interference by enclosing the cutting area, ensuring high cutting precision while providing a cleaner and safer working environment.

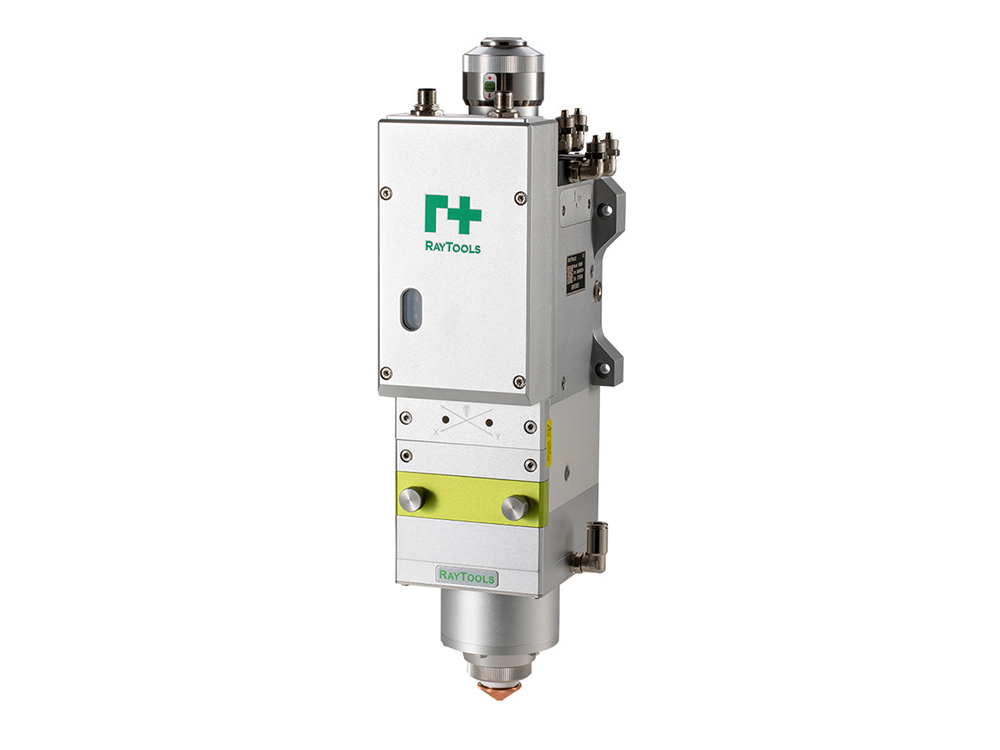

Intelligent Laser Cutting Head

Cutting head uses an advanced optical system, adaptive focusing functions and high-speed sensors to ensure optimal cutting performance of various materials. With automatic height adjustment, anti-collision technology, and real-time monitoring, it can improve accuracy and reduce downtime.

Fiber Laser Source

The laser beam output by the fiber laser is of high quality and strong focusing ability. It can achieve finer cutting effect and is suitable for applications with higher precision requirements. Compared with traditional lasers, fiber lasers are energy efficient, low operating costs, and are environmentally friendly.

High Precision Screw Transmission

The screw drive has small gaps and high positioning accuracy, which is suitable for scenes that require fine cutting and complex patterns. During long-term operation, the screw drive maintains high stability and is not prone to positioning deviation.

Fiber Laser Cutting Machine - Other Core Components

Intelligent Operating System

Japan SHIMPO Reducer

Taiwan Hiwin Rails & YYC Gears

Water Chiller

▍3030 Laser Cutting Machine Benefits

-

Compact Design for Versatile Applications

The Mini Enclosed 3030 Laser Cutting Machine is specifically designed for small-scale precision cutting applications. Its compact footprint makes it ideal for businesses with limited space, while its robust construction ensures stable and reliable performance.

-

Advanced Features for Precision and Efficiency

The 3030 model is equipped with a high-precision autofocus laser head to ensure that every cut is clean and accurate. The intelligent CNC control system supports automatic edge detection, easy file imports, and optimized nesting, reducing material waste and enhancing efficiency. These advanced features, combined with user-friendly operation, allow even novice operators to achieve professional-grade results.

-

Safe and Eco-Friendly Operation

The fully enclosed design of the Mini 3030 not only enhances operator safety by isolating the cutting process but also ensures compliance with environmental standards. Additionally, the enclosure reduces noise during operation, contributing to a more comfortable working environment.

Contact us now to explore our fiber laser cutters. Fill out the form for a personalized quote. Our team is ready to provide you with tailored solutions and support.