Fiber Laser Cutting Video On Youtube

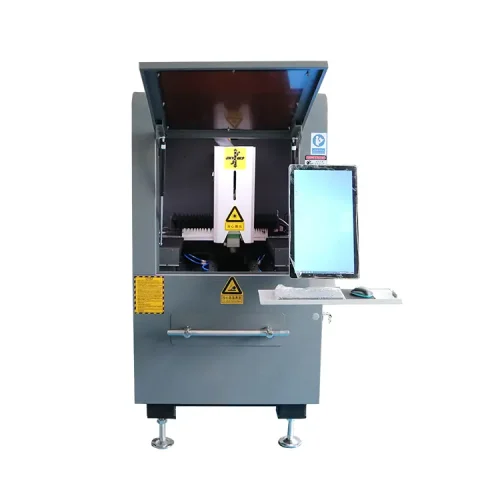

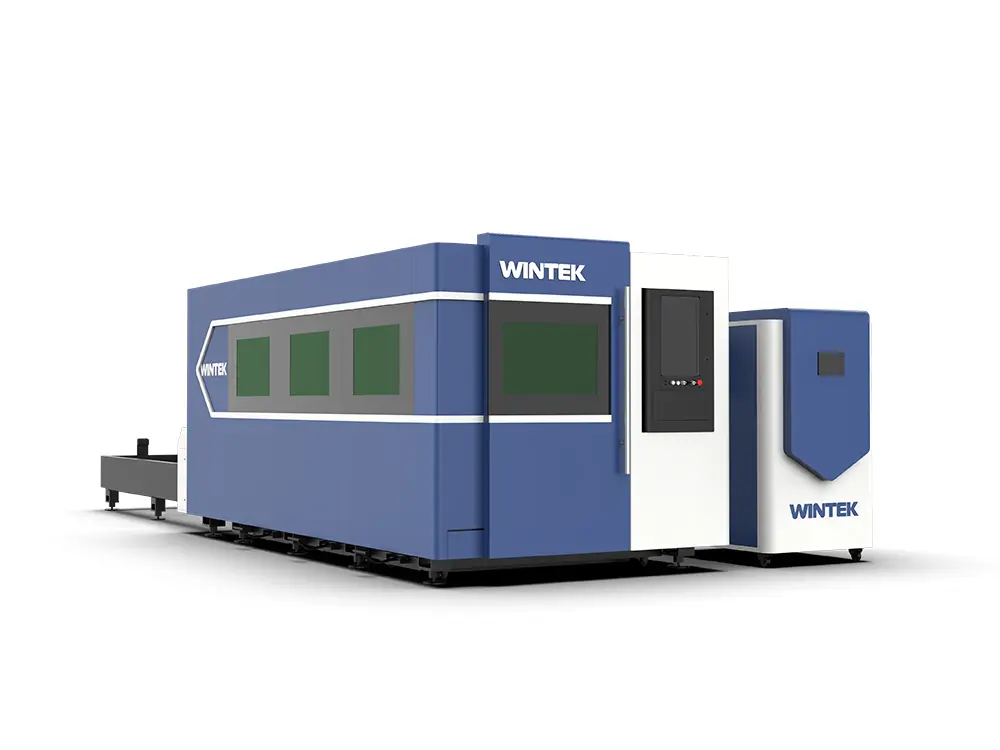

Bevel Laser Cutting Machine Description

Equipped with a dedicated five-axis laser processing intelligent control system, it effortlessly achieves various bevel types such as V, Y, X, and K with cutting angles up to ±45°. The zero-gap cutting design significantly reduces welding difficulty and cost, streamlines processes, and enhances sheet metal processing efficiency.

Featuring a renowned brand fiber laser, it ensures excellent beam quality, minimal thermal deformation, and smooth, aesthetically pleasing cuts. The seamless cutting process eliminates the need for secondary processing, enabling workpieces to be directly used for welding, reducing production steps, manufacturing costs, and labor expenses while greatly improving overall production efficiency.

High-precision servo control and reducer coordination ensure the cutting head’s motion accuracy, minimizing bevel angle errors for processed parts. This makes it ideal for large-scale, high-precision bevel component production with stable and reliable quality.

With kilowatt-level laser power and multi-axis linkage technology, it handles bevel cutting of metal plates up to 60mm thick effortlessly, broadening processing capabilities and enhancing production efficiency and flexibility.

UPGRADE SERIES

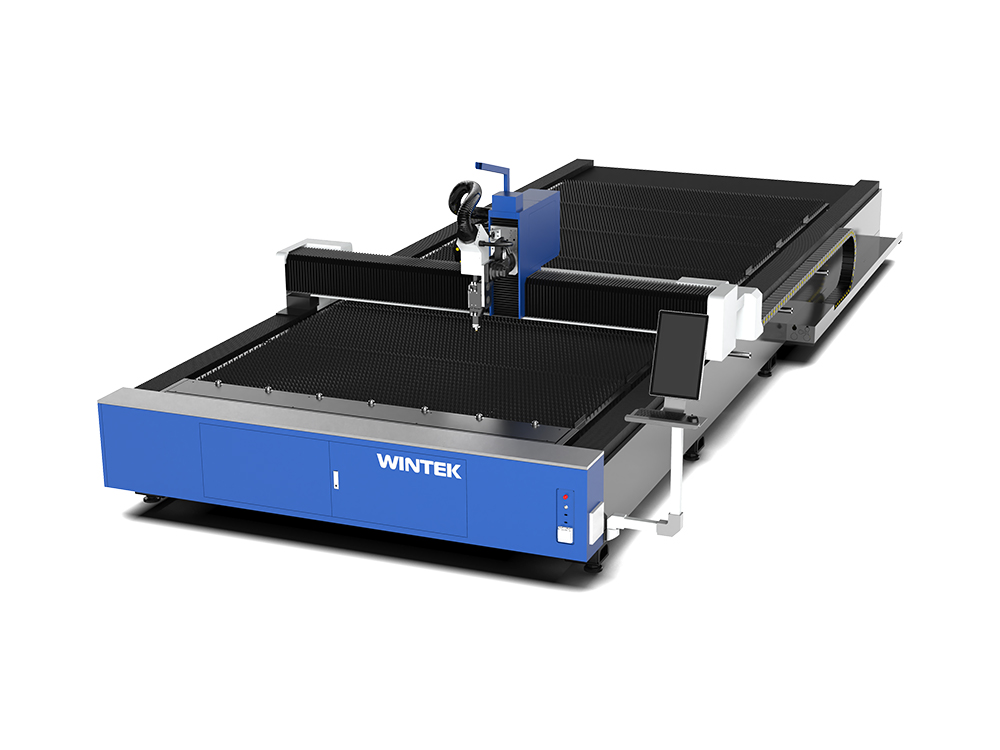

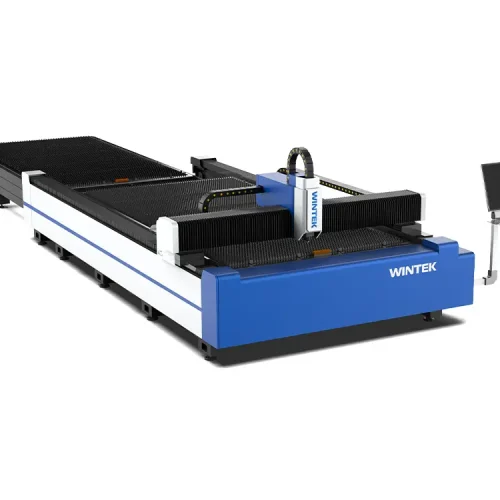

AE – series

The fiber laser cutting machine features a 10-15s exchange platform, enabling rapid material changes to boost productivity and minimize downtime.

DETAILS

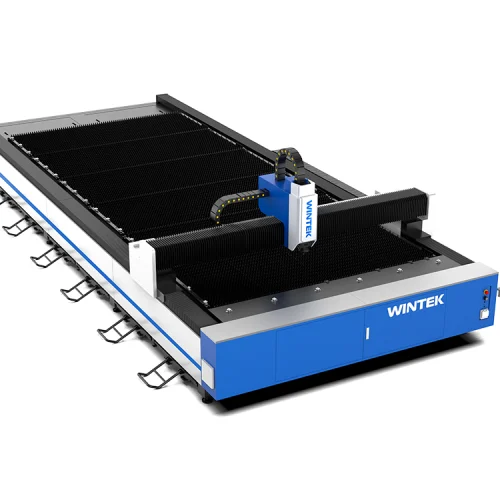

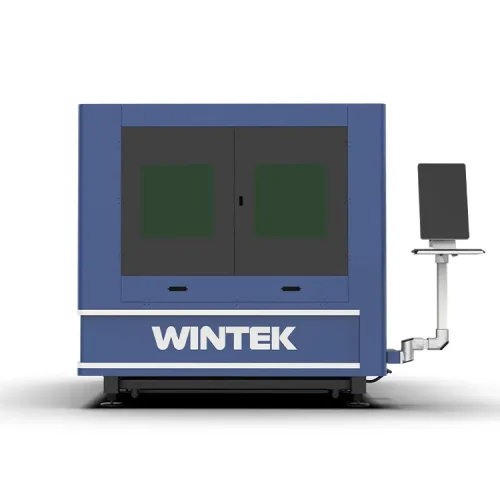

AT – series

This fiber laser cutting machine can cut sheets and tubes, combining two functions in one to save costs. It can cut plates up to 35mm thick and pipes up to 6m/350mm.

DETAILS

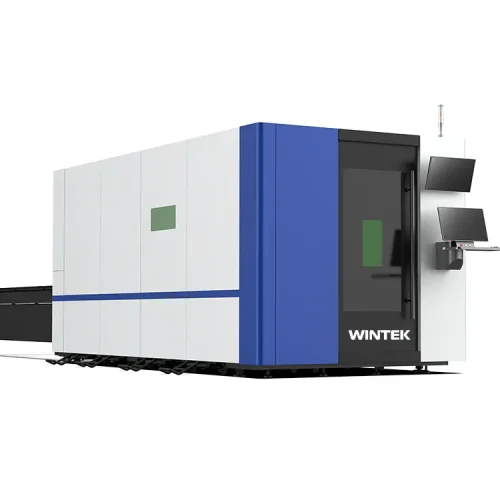

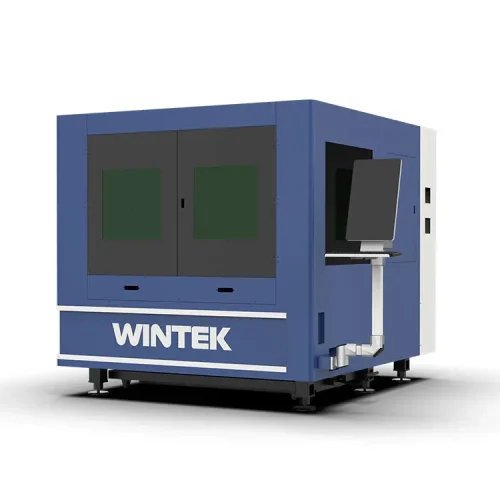

P – series

The fully enclosed fiber laser cutting machine ensures maximum safety, reduced noise, and improved efficiency, making it ideal for high-precision industrial applications.

DETAILSTechnical Parameters

Below is a summary of the key specifications for the bevel laser cutting machine, highlighting its performance metrics. It is designed for precision and efficiency and is an ideal solution for various industrial cutting needs.

| Product Name | WT6020AB |

| Laser Power | 6KW-30KW |

| Laser Wave Length | 1064nm |

| Position Accuracy | 0.03 mm/m |

| Repeatability Accuracy | 0.02 mm/m |

| Acceleration | 0.8G-1.5G |

| Cutting Speed | 80-140 m/min |

| Interface | USB, RJ45 |

| Working Voltage | 380v, 3phase, 50hz/60hz (customized) |

| Auxiliary Gas | oxygen, nitrogen, compressed air |

| Work Environment | 0-45°C, Moisture 45-85% |

| Machine Size / Packing Size | 8000*2700*1950mm/8100*2800*2300mm |

Fiber Laser Cutting Machine Sample

Machine Configuration

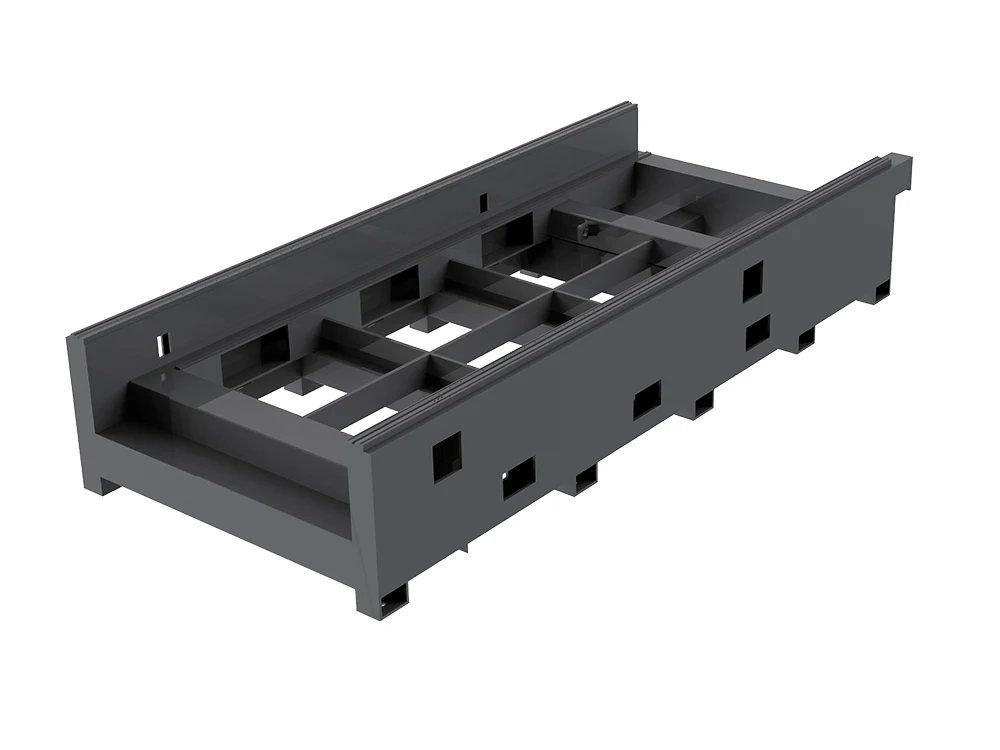

Strong Plate Welded Bed

Strict heat treatment eliminates stress and prevents deformation caused by temperature changes in the bed material, ensuring long-term stable operation. Special shock-absorbing structures and materials absorb vibrations during work, improving cutting accuracy and stability.

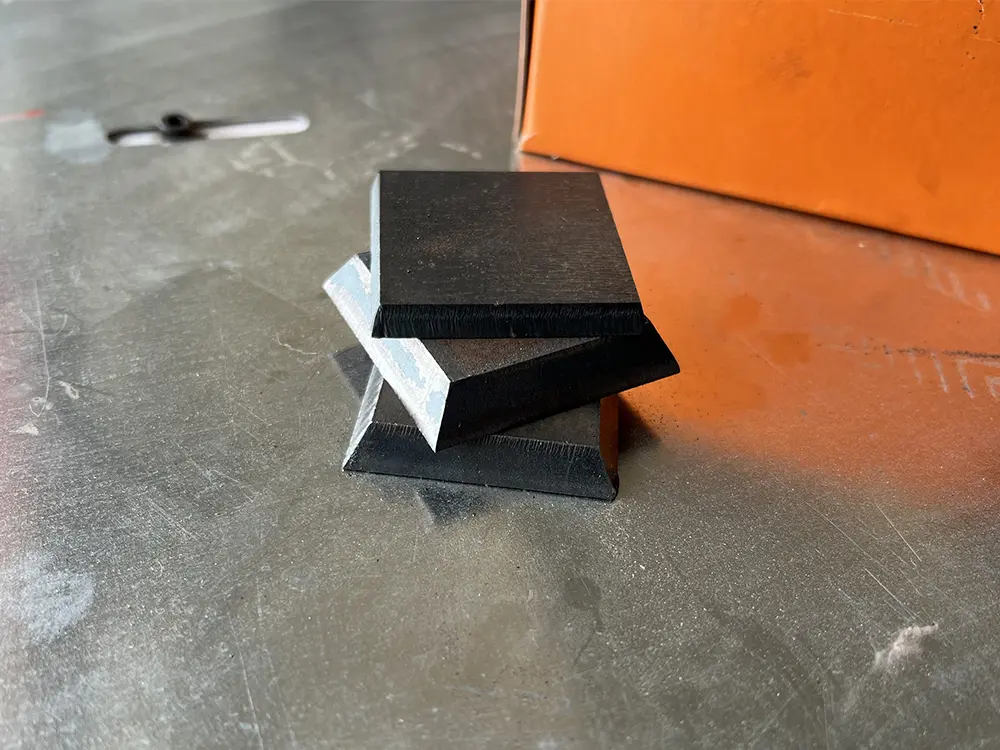

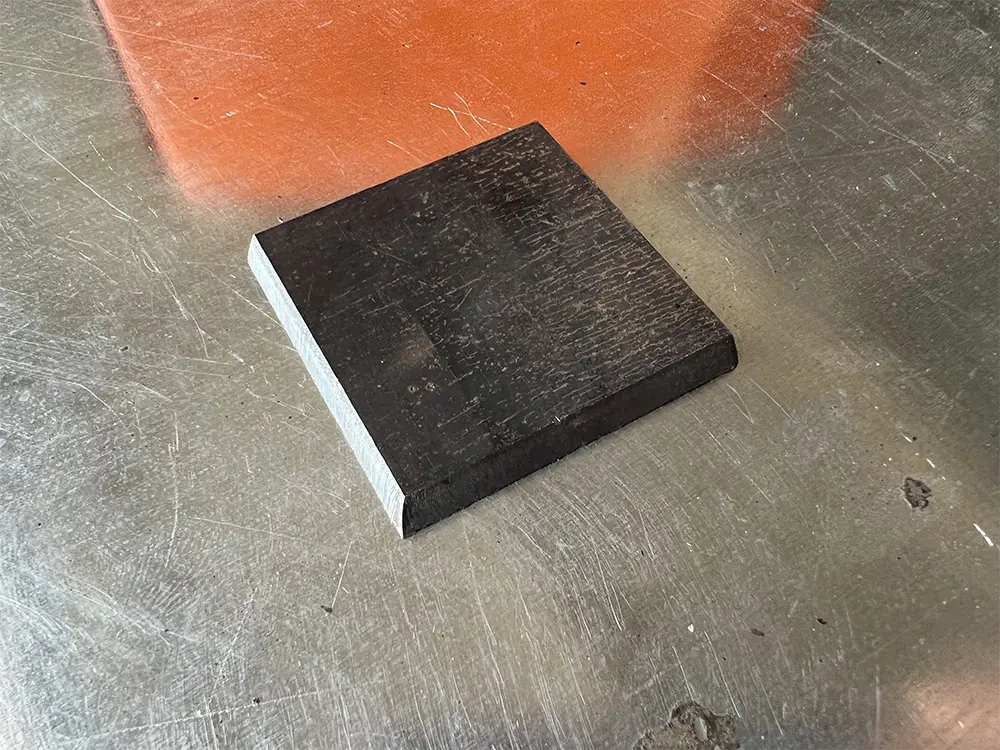

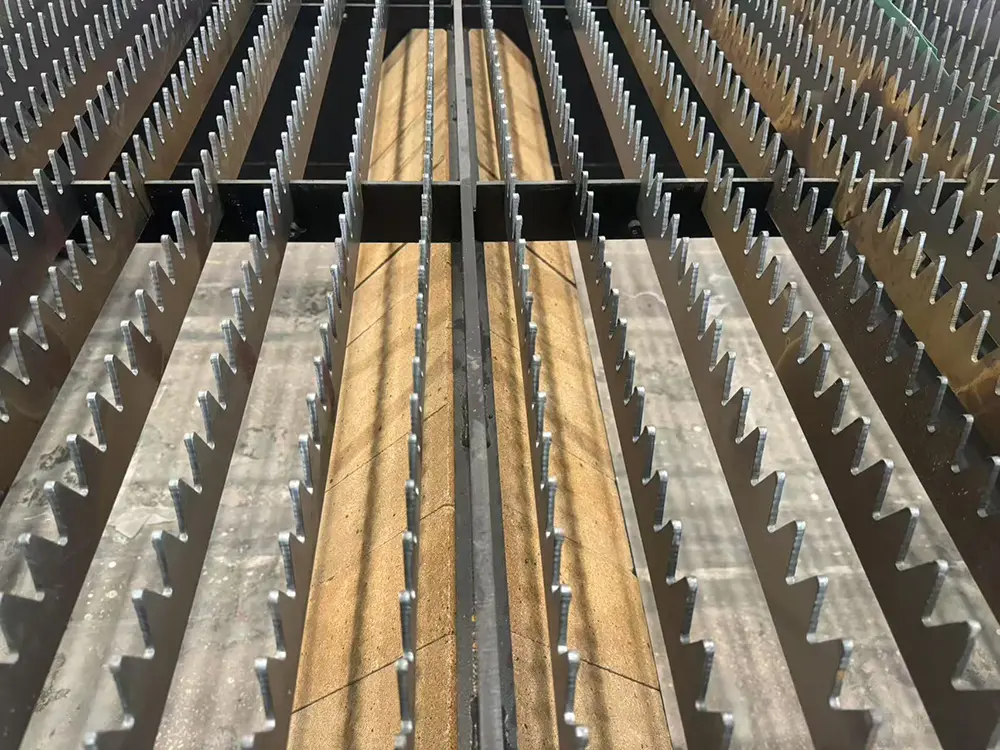

High Temperature Resistant Bricks

Fire bricks can withstand the high temperatures generated during laser cutting, preventing high temperatures from damaging the workbench surface or the structure under the cutting platform. Prevent slag from falling onto fire bricks to avoid direct contact with machine tool metal parts.

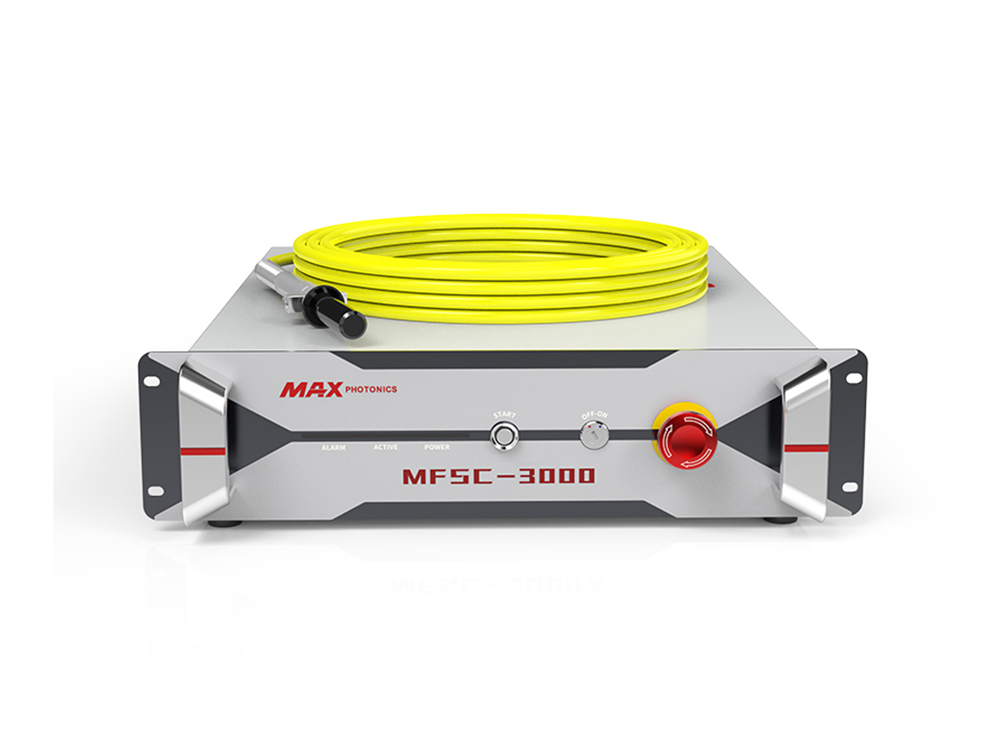

Fiber Laser Source

The laser beam output by the fiber laser is of high quality and has strong focusing ability. It can achieve finer cutting effects and is suitable for applications with higher precision requirements. The fiber laser has high electro-optical conversion efficiency, simple and stable structure, and low maintenance cost.

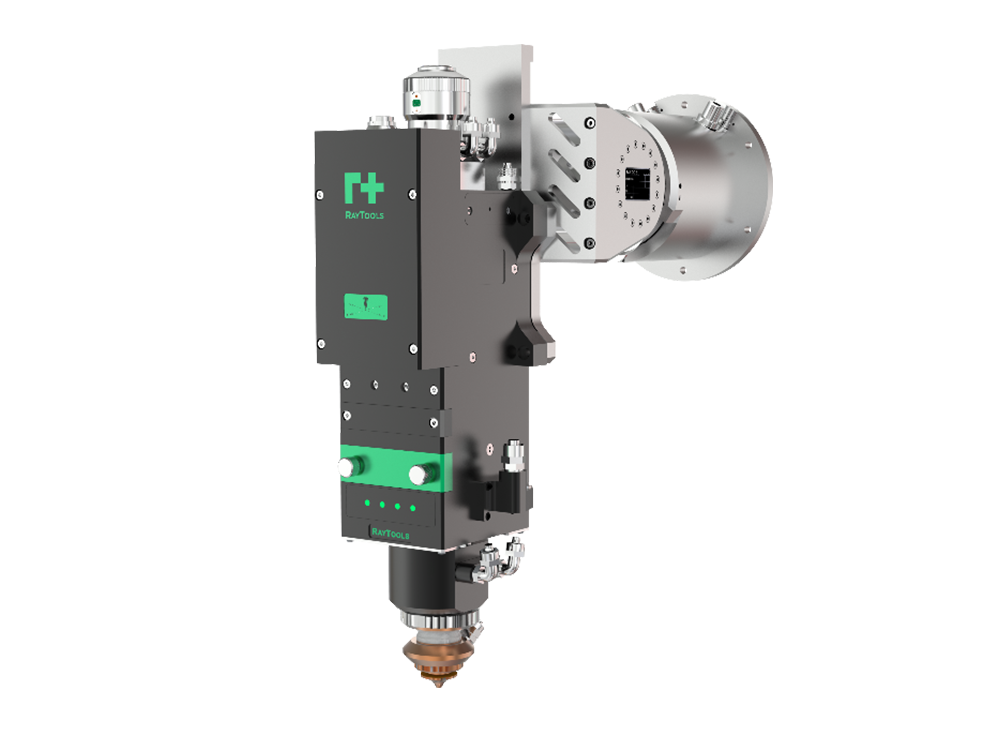

Bevel Laser Cutting Head

The bevel laser cutting head can achieve multi-angle bevel processing from 0° to 45°, and supports V-type, Y-type, X-type, and K-type bevels. The built-in water cooling system effectively reduces the temperature of the cutting head, prevents overheating, and increases service life.

Bevel Laser Cutting Machine - Other Core Components

Water Chiller

Aviation Aluminum Beam

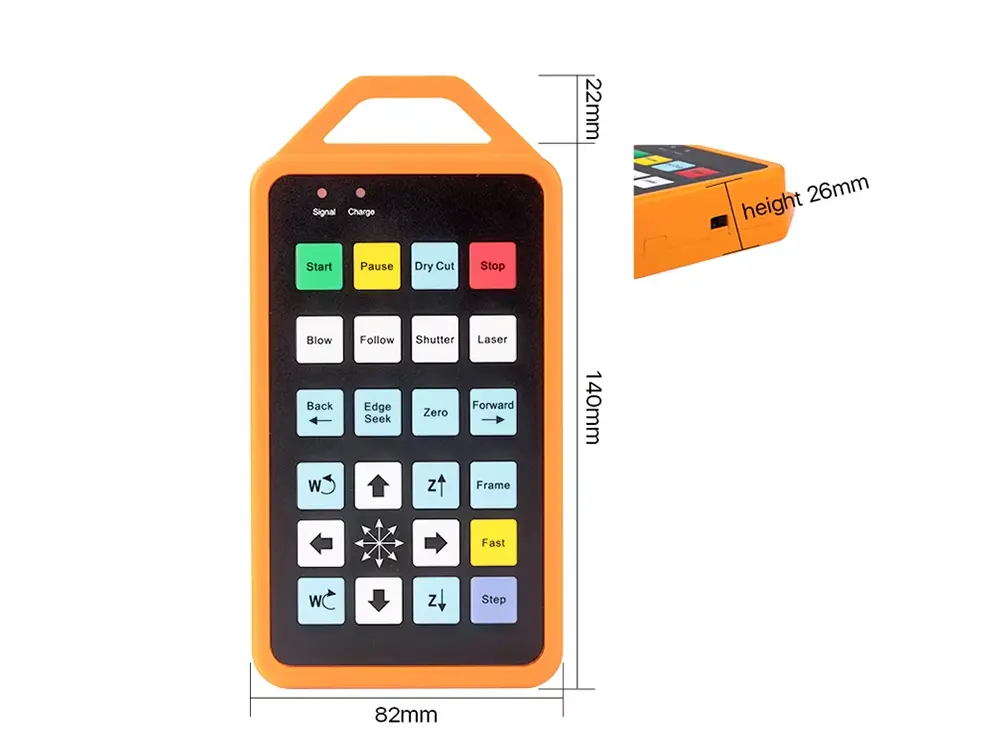

Wireless Handheld Control

Japan Servo Motor and Driver

Fiber Optic Laser Cutter Benefits

Wintek bevel fiber laser cutting machine adopts imported fiber laser with good beam quality, small thermal deformation and good cutting quality.

The CNC system can precisely control all axes, breaking through the conventional straight cutting method, and realizing bevel cutting with a swing of not less than ±45° on both axes. Different styles of bevels such as Y-type, V-type and X-type are formed at one time, which reduces the process, splices zero gap, reduces the difficulty of welding, and greatly improves the efficiency of sheet metal processing.

Professional laser cutting software with graphic layout and sharp corner smoothing functions can realize high-speed punching and fast cutting functions. It has function detection, automatic diagnosis, fault isolation, fault analysis and data display system, and can quickly troubleshoot and effectively reduce after-sales service costs.

Feel free to contact us now for more details!

Our team is ready to provide you with tailored solutions and support.